Customized Aluminium Tuag Casting Tsev

Khoom Paub meej

Vim li cas Aluminium Tuag Casting?

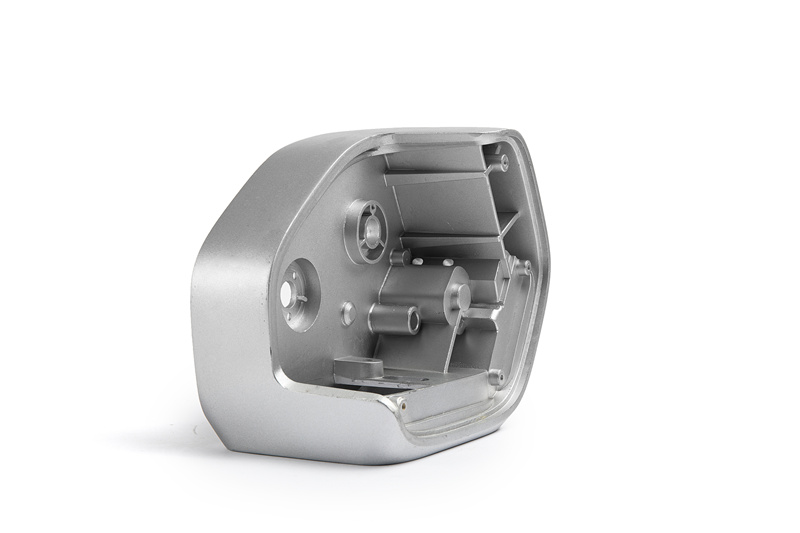

Qhov zoo tshaj plaws ntawm txhuas tuag casting piv rau lwm cov txheej txheem xws li machining, los yog cov ntawv hlau sib sau yog tias txhuas tuaj yeem tsim cov qauv 3D zoo heev ntawm tus nqi qis.Vim li no, manufacturers muaj peev xwm xaj customized castings uas zoo tagnrho rau lawv cov kev xav tau ntau lawm.Aluminium tuag castings tuaj yeem tig cov hlau molten mus rau hauv qhov ze-net zoo ib feem hauv vib nas this, yog li machining lossis lwm yam haujlwm yuav luag raug tshem tawm.

Tuag Casting txheej txheem

1. Kev kos duab tsim:

DFM yog ib txoj hauv kev zoo tshaj plaws ua raws li Xiamen Ruicheng engineers los ua kom zoo tshaj qhov kev tsim khoom ntawm castings thaum tuav kev ua haujlwm.Xiamen Ruicheng muaj pab pawg ntau tshaj kaum tus kws tshaj lij engineers uas yuav muab cov lus qhia zoo ntawm cov khoom siv thiab nrhiav kev sib npaug ntawm kev tsim, nqi thiab kev ua haujlwm ib feem.

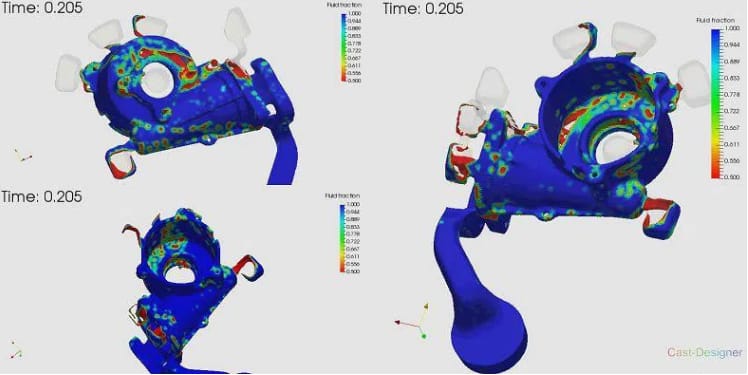

2. Pwm Tsim:

Cov pwm theem simulates cov txheej txheem filling thiab solidification, kwv yees qhov tsis xws luag uas yuav tshwm sim nyob rau hauv tuag casting, thiab kwv yees lub microscopic hlau thiab txhua yam khoom, thiab lub zog ntawm pwm ejector tus pin.Optimize khiav thiab rooj vag tsim, txhim kho cov txheej txheem ntau lawm, txo R & D thiab cov nqi tsim khoom, thiab txhim kho cov khoom lag luam zoo.

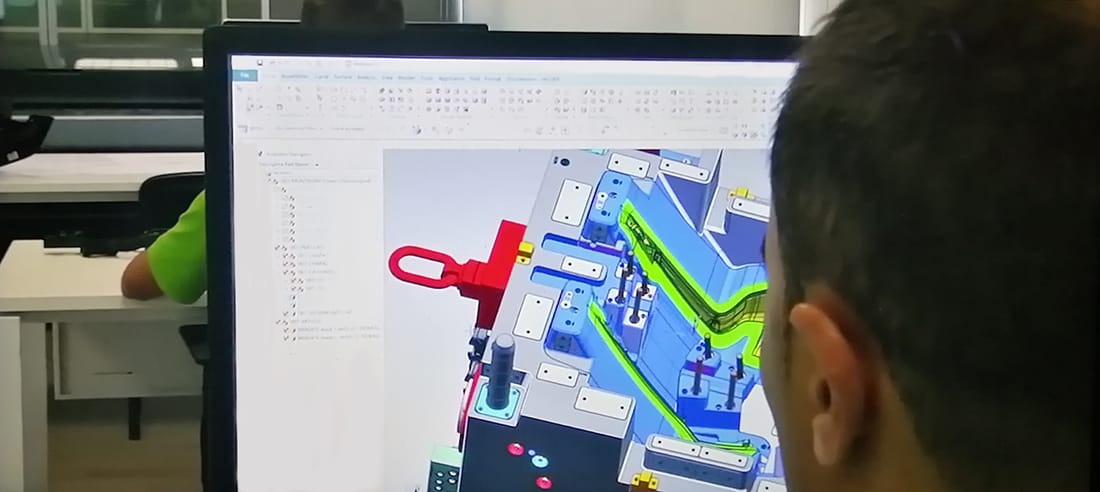

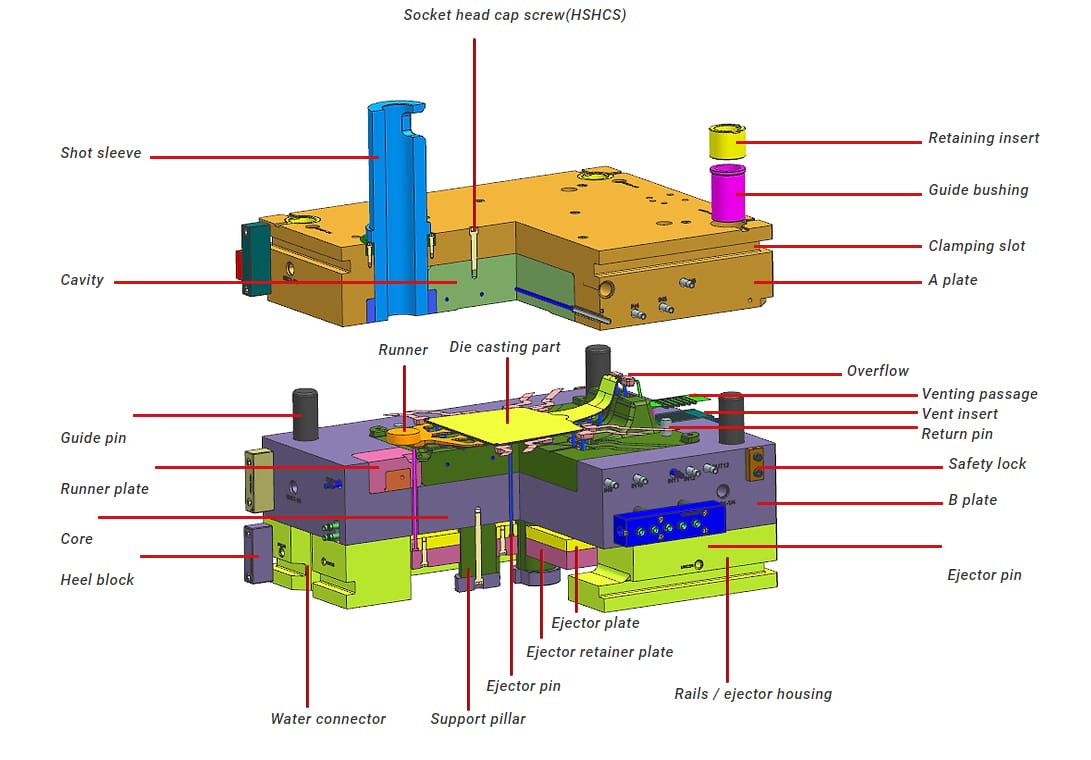

3. Pwm Manufacturing:

peb muab ob hom kev siv cuab yeej sib txawv: ntau tus swb thiab cov pa.Txhua tus muaj lawv tus kheej cov txiaj ntsig tshwj xeeb thiab peb cov kws tshaj lij engineers tuaj yeem pab txiav txim siab seb cov cuab yeej twg yog qhov zoo tshaj plaws rau txhua qhov haujlwm.Cov txheej txheem ntawm kev tsim cov khoom raws li cov pwm tsim duab kos duab, siv cov tshuab txiav, lub tshuab hluav taws xob, kev kho deg thiab kev kho cua sov, thiab thaum kawg sib sau tag nrho cov khoom rau hauv pwm raws li tus qauv tsim.

4.Die-Cast Muaj peev xwm:

Xiamen Ruicheng yog ib qho ntawm ob peb lub tuam txhab uas muaj peev xwm nthuav dav cov khoom lag luam, nrog cov tshuab tuag casting ntawm 58-3000 tons ntawm cov tonnage sib txawv.Nws tuaj yeem tsim qhov hnyav 5g-35kg.Lub tshuab hluav taws xob ywj pheej ntawm txhua lub tshuab tuag casting ua rau peb muab ntau yam txhuas, zinc, magnesium thiab lawv cov alloys kom tau raws li qhov tshwj xeeb ntawm cov neeg siv khoom.

5.Muaj peev xwm kho qhov saum npoo:

Nrog ntau tshaj 10 xyoo dhau los hauv kev tsim khoom tuag Casting, Xiamen Ruicheng tuaj yeem ua tiav kev kho lub cev, tshuaj pleev xim, hmoov txheej, anodizing thiab chrome plating, tshwj xeeb tshaj yog cov anodizing.Muaj ob peb tus neeg muag khoom hauv Suav teb uas tuaj yeem Anode Oxidation tuag castings zoo heev.

6. Muaj peev xwm ua ke:

Xiamen Ruicheng muab cov neeg siv khoom nrog ntau yam kev sib dhos thiab cov kev pabcuam sub-sembly.Peb muaj kev paub dhau los hauv kev sib dhos cov khoom siv, suav nrog cov ntsia hlau, ntsia hlau, bolts, pins, ntxig, gaskets thiab O-rings, thiab ntsuas kev ntsuas siab kom ntseeg tau cov khoom ua haujlwm.

7. Kev soj ntsuam zoo:

Xiamen Ruicheng them nyiaj tshwj xeeb rau kev tswj kom zoo ntawm cov txheej txheem ntau lawm thiab tau tsim kom tiav cov txheej txheem tshuaj xyuas zoo thiab cov txheej txheem.Muaj tsib yam cuab yeej siv: PPAP, APQP, PFMEA, SPC, thiab MSA.Tag nrho cov khoom raug soj ntsuam tag nrho lossis tsim ua raws li cov qauv.Cov khoom siv kuaj muaj xws li: spectrometer, stretching Testing tshuab, CMM peb-coordinate, pass-stop gauge, parallel gauge, ntau yam calipers, thiab lwm yam., kom ua tiav cov kev tswj muaj peev xwm ntawm lub system zoo.