Cia peb tham txog yam peb tuaj yeem tsim, tsim, ntsuas ua ke.

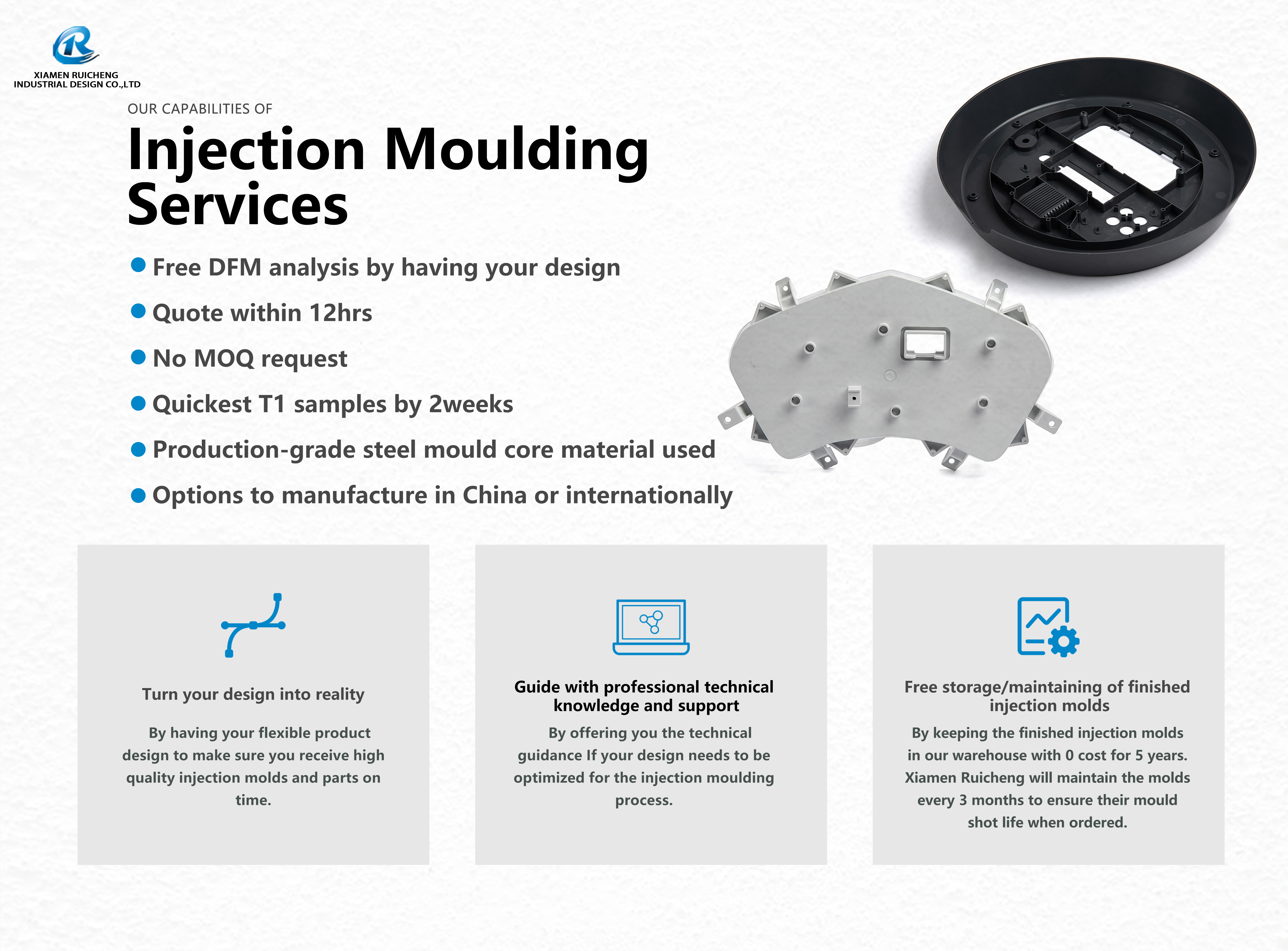

Ua ntej txhua yam yas txhaj pwm txiav, nws yog ib qho tsim nyog yuav tsum tau ua nws qhov kev tshuaj ntsuam DFM kom paub tseeb tias nws tuaj yeem raug txhaj tshuaj zoo meej los ntawm kev tshawb pom seb puas muaj kev txhim kho tsim nyog.Kev vam meej yog txhais los ntawm qhov tshwm sim, cov yeeb yaj kiab yog qhov piv txwv ua haujlwm tseem ceeb uas tuaj yeem pab koj kom nkag siab txog qhov txheej txheem pes tsawg.Hu rau peb tam sim no kom tau txais daim ntawv tshaj tawm DFM dawb yog tias koj tab tom tsim cov khoom tshiab.

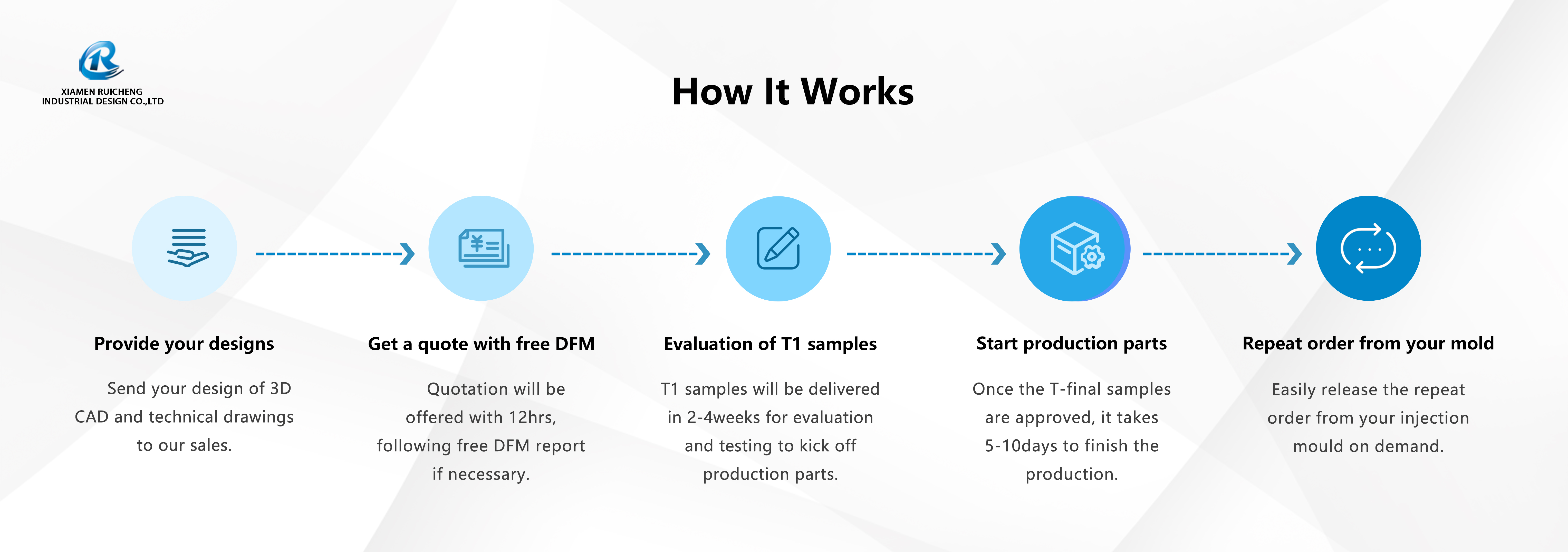

Cov txheej txheem txhaj tshuaj molding

Kev txhaj tshuaj pwm sai

Kev txhaj tshuaj pwm nrawm nrog lub sijhawm ua haujlwm ceev, zoo tagnrho rau kev tsim qauv thiab cov khoom siv me me uas yog rau kev tsim qauv siv rau kev tsim choj.

Overmolding

Cov txheej txheem overmolding cia koj muab ntau yam ntaub ntawv rau hauv ib feem.Ib qho khoom siv, feem ntau yog cov thermoplastic elastomer (TPE / TPV / TPU) yog molded mus rau ib qho khoom thib ob uas feem ntau yog cov yas tawv.Los yog kom overmould hlau ntxig rau hauv cov yas.

Ob-xim pwm

Ob-xim txhaj tshuaj molding yog txheej txheem tsim khoom siv thaum xa mus rau pwm ob cov ntaub ntawv / xim rau hauv ib feem yas, uas yog cov cuab yeej siv ob qho khoom lossis ob xim sib txawv rau hauv ib qho kawg yas los ntawm kev siv 2k txhaj tshuaj molding tshuab.

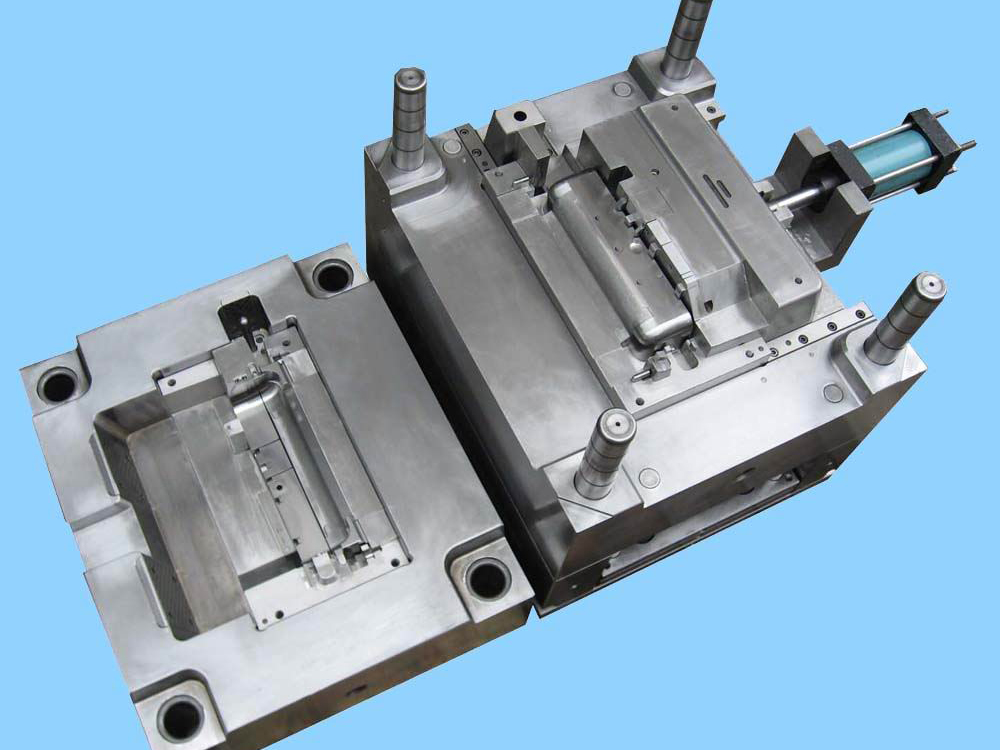

Loj ntau lawm txhaj pwm

Kev Txhaj Tshuaj Molding yog txheej txheem tsim khoom uas koom nrog kev txhaj tshuaj molten rau hauv pwm kab noj hniav los ntawm kev siv qib steel pwm cov khoom uas tuaj yeem ua rau nws lub neej txhaj tshuaj ntau tshaj 200,000cycles.

Txhaj Molding tiav

| Glossy | Semi-Glossy | Matte | Textured |

| SPI-A2 SPI-A3 | SPI-B1 SPI-B2 SPI-B3 | SPI-C1 SPI-C2 SPI-C3 | MT (Moldtech) VDI (Verein Deutscher Ingenieure) |

Txhaj Moulding Khoom

ABS

Acrylonitrile Butadiene Styrene (ABS) yog ib qho thermoplastic uas yog tsim los ntawm emulsion.Nrog rau nws cov Strong, saj zawg zog, tsis tshua muaj pwm shrinkage (nruj tolerances), tshuaj tsis kam, electroplating muaj peev xwm, ib txwm opaque, tsawg / nruab nrab nqi.

Cov ntawv thov siv: Automotive (consoles, panels, trim, vents), thawv, gauges, vaj tse thiab khoom ua si.

Acetal / POM (Delrin)

POM yog ib qho kev sib txhuam qis, lub teeb yuag thermoplastic uas muaj zog thiab nruj nrog kev qaug zog zoo heev, kev nkag siab zoo heev, tshuaj lom neeg tsis kam thiab noo noo tsis kam nyob rau hauv ib txwm opaque dawb nrog tus nqi qis / nruab nrab.

Cov ntawv thov siv:Bearings, cams, gears, handles, rollers, rotors, swb guides, li qub

PC(Polycarbonate)

PC yog tawv heev nrog kub tsis kam thiab qhov ntev stability, tuaj yeem ua pob tshab tab sis tus nqi siab.

Cov ntawv thov siv:Automotive (panels, lo ntsiab muag, consoles), fwj, ntim, vaj tse, lub teeb npog, reflectors, kaus mom hlau thiab ntaub thaiv npog

PC + iav-Filled

Cov iav uas muaj Polycarbonate yog cov khoom siv muaj zog thiab tawv zoo tagnrho rau ntau daim ntawv thov kev lag luam.

Cov ntawv thov siv:Pulleys, khoom siv kho mob

PMMA (Acrylic)

PMMA yog pob tshab polymer nrog zoo tensile, khawb resistant, tuaj yeem ua pob tshab thiab pom tseeb hauv tus nqi qis / nruab nrab

Cov ntawv thov siv:zaub sawv, pob qhov rooj, lo ntsiab muag, lub teeb vaj tsev, panels, reflectors, kos npe, txee, tais

PP (Polypropylene)

PP yog nyob rau hauv lub teeb yuag nrog kub tsis kam, siab tshuaj tsis kam, khawb kuj thiab ntuj waxy tsos uas yog tawv thiab tawv nyob rau hauv tus nqi qis.

Cov ntawv thov siv:Automotive (bumpers, npog, trim), fwj, kaus mom, crates, tes, vaj tse

PP++ iav-Filled

Iav Filled PP Compound yog tsim los ntawm kev sib xyaw Polypropylene Homo-Polymer nrog qib zoo ntawm iav, nrog rau qib tsim nyog ntawm kev pab cuam, Thaum tshav kub kub stabilizer thiab Anti-oxidant.

Cov ntawv thov siv:Housing handles, enclosures

PE (Polyethylene)

PE muaj qhov tsis tshua muaj melting point, siab ductility, siab cuam tshuam lub zog, thiab tsis tshua muaj kev sib txhuam.

Cov ntawv thov siv:Zaj duab xis, hnab, hluav taws xob rwb thaiv tsev, khoom ua si.

LDPE(Polyethylene - Tsawg ntom)

LDPE yog mos, hloov tau, tawv, thiab lub teeb yuag nrog zoo corrosion kuj nyob rau hauv tej yam ntuj tso waxy tsos thiab tsis tshua muaj nqi.

Cov ntawv thov siv:Ntim, hnab, tubing, chav ua noj, vaj tse, npog

HDPE (Polyethylene - High Density)

HDPE yog tawv thiab tawv nrog cov tshuaj tiv thaiv zoo heev, lub zog tensile siab, siab cuam tshuam tsis kam thiab siab melting point.

Cov ntawv thov siv:Lub rooj zaum, vaj tse, npog, ntim thiab kaus mom

Nylon - iav ntim & 6/6

Nylon 6/6 muaj zog txhua yam thiab rigidity nrog qaug zog tsis kam, tshuaj tiv thaiv nyob rau hauv qis creep thiab tsis tshua muaj kev sib txhuam nrog nruab nrab / siab nqi

Cov ntawv thov siv:kov, levers, me me vaj tse, zip ties & zog, bushings

Nylon - Cov iav Filled muaj zog ntau dua thiab muaj zog tensile zoo dua li tus qauv Nylon.Nws kuj muaj cov coefficient tsawg ntawm kev sib txhuam thiab siab thermal kuj.

Cov ntawv thov siv:Bearings, ntxhua khaub ncaws, lub teeb yuag hloov rau cov hlau yog qhov tsim nyog

ASA (Acrylonitrile Styrene Acrylate)

ASA yog ABS lwm txoj hauv kev nrog kev txhim kho huab cua.

Cov ntawv thov siv:Automotive qhov chaw Enclosures, loj panels

HIPS(High Impact Polystyrene)

HIPS yog ib qho yooj yim rau pwm, rov ua dua, thiab muaj kev cuam tshuam siab zog thiab nruj.

Cov ntawv thov siv:Packing, tais diav, zaub

GPPS (Polystyrene - Lub hom phiaj dav)

GPPS yog nkig, pob tshab tab sis tus nqi qis.

Cov ntawv thov siv:Kev ntim cov tshuaj pleev ib ce, cwjmem

PBT (Polybutylene Terephthalate)

PBT zoo ib yam li PET yas thiab ib tug tswv cuab ntawm tsev neeg polyester.PBT yog qhov zoo dua los ua kom qis molding thiab siv qhov kub thiab txias.Nws muaj kev kub siab thiab tshuaj lom neeg.

Cov ntawv thov siv:Automotive (filters, handles, twj), bearings, cams, hluav taws xob Cheebtsam (connectors, sensors), gears, vaj tse, rollers, keyboards

PBT +iav puv

Iav-filled PBT muaj zog ntau dua thiab muaj zog tensile ntau dua li tus qauv PBT.Nws kuj muaj qhov kub thiab txias thiab tshuaj tiv thaiv.

Cov ntawv thov siv:automotive applications, Fire-retardant applications

PET (Polyethylene terephthalate)

PET yog cov khoom siv ntau tshaj plaws rau lub raj mis yas dej thiab lwm yam dej haus.Nws tseem yog feem ntau hu ua polyester thiab yog siv los ua hluavtaws fibers.

Cov ntawv thov siv:Yas dej fwj, ntim

PC/ABS

PC / ABS yog ib qho kev sib xyaw ntawm polycarbonate thiab ABS uas yog kom tau txais cov khoom zoo tshaj plaws ntawm ob lub hauv paus ntaub ntawv - kub tsis kam thiab yoog raws.Qhov kev sib xyaw no tseem ua tau yooj yim dua thaum txhaj tshuaj molding dua li ntawm cov ntaub ntawv hauv paus.

Cov ntawv thov siv:Enclosures, loj panels;

PVC (Polyvinyl Chloride)

PVC muaj zog hardness, mechanical thiab hluav taws xob rwb thaiv tsev.Nws yog tshuaj resistant rau ntau cov kua.

Cov ntawv thov siv:Cov thawv kho mob, cov khoom siv hauv tsev, cov kav dej, cables

PEI (ULTEM)

PEI yog cov yas xim amber nrog kub tsis kam thiab siab dielectric zog, ua rau nws zoo rau cov khoom siv kho mob thiab cov hluav taws xob rwb thaiv tsev.

Cov ntawv thov siv:Cov khoom siv hluav taws xob (connectors, boards, keyboards), npog, Cov khoom siv kho mob

PEEK (Polyetheretherketone)

PEEK muaj qhov kub thiab txias, tshuaj lom neeg, thiab hluav taws xob tiv thaiv nrog kev nqus dej tsawg.

Cov ntawv thov siv:Aircraft Cheebtsam, hluav taws xob connectors, twj impellers, seals

PPS (Polyphenylene Sulfide)

PPS muaj lub zog siab heev thiab kub ua haujlwm nrog cov dej ntws zoo thiab qhov ruaj khov.

Cov ntawv thov siv:roj system Cheebtsam, kev taw qhia, keyboards, hluav taws xob rwb thaiv tsev, daim nyias nyias, ntim

PPO (Polyphenylene Oxide)

PPO muaj qhov zoo ntawm qhov ruaj khov thiab cov khoom siv hluav taws xob zoo nrog kev nqus dej tsawg thiab tus nqi siab

Cov ntawv thov siv:Automotive (tsev, vaj huam sib luag), cov khoom siv hluav taws xob, vaj tse, cov kav dej

PPA (Polyphthalamide)

PPA yog piv rau nylon nrog ntau zog, lub zog, thiab thermal zog.Nws muaj zoo creep kuj thiab dimensional stability.

Cov ntawv thov siv: Automotive, roj thiab roj, cov kav dej

SAN (Styrene Acrylonitrile)

SAN (AS) yog cov khoom siv polystyrene nrog cov thermal thiab tshuaj lom neeg ntau dua thiab muaj zog hydrolytically ruaj khov.

Cov ntawv thov siv:Cov khoom siv hauv tsev, pob qhov rooj, koob txhaj tshuaj

TPE (Thermoplastic Elastomer)

TPE muaj lub ntsej muag zoo li cov khoom siv roj hmab tab sis yog cov thermoplastic uas tuaj yeem rov ua dua.TPE muaj cov khoom siv thermal zoo thiab ruaj khov ntawm ntau qhov kub thiab txias uas tuaj yeem ua rau sib txawv hardness.

Cov ntawv thov siv:Automotive applications, khoom siv hauv tsev

TPU (Thermoplastic polyurethane)

TPU yog cov khoom siv elastic nrog zoo tiv taus roj, roj, thiab puas.

Cov ntawv thov siv:Kev siv cov cuab yeej kho mob, mobile electronic devices

TPV (Thermoplastic Vulcanizates)

TPV yog ib feem ntawm TPE khoom tsev neeg.Nws muaj qhov ze tshaj plaws hauv cov khoom rau EPDM roj hmab thiab muaj qhov kub thiab txias tsis kam thiab elastisity zoo heev.

Cov ntawv thov siv:Automotive daim ntaub ntawv, khoom siv hauv tsev, sealing daim ntaub ntawv

PS: Peb tuaj yeem muab cov ntaub ntawv kev cai raws li kev thov kom ua tau raws li koj cov khoom siv raws nraim daim ntawv thov

Kev ua haujlwm thib ob tom qab txhaj tshuaj

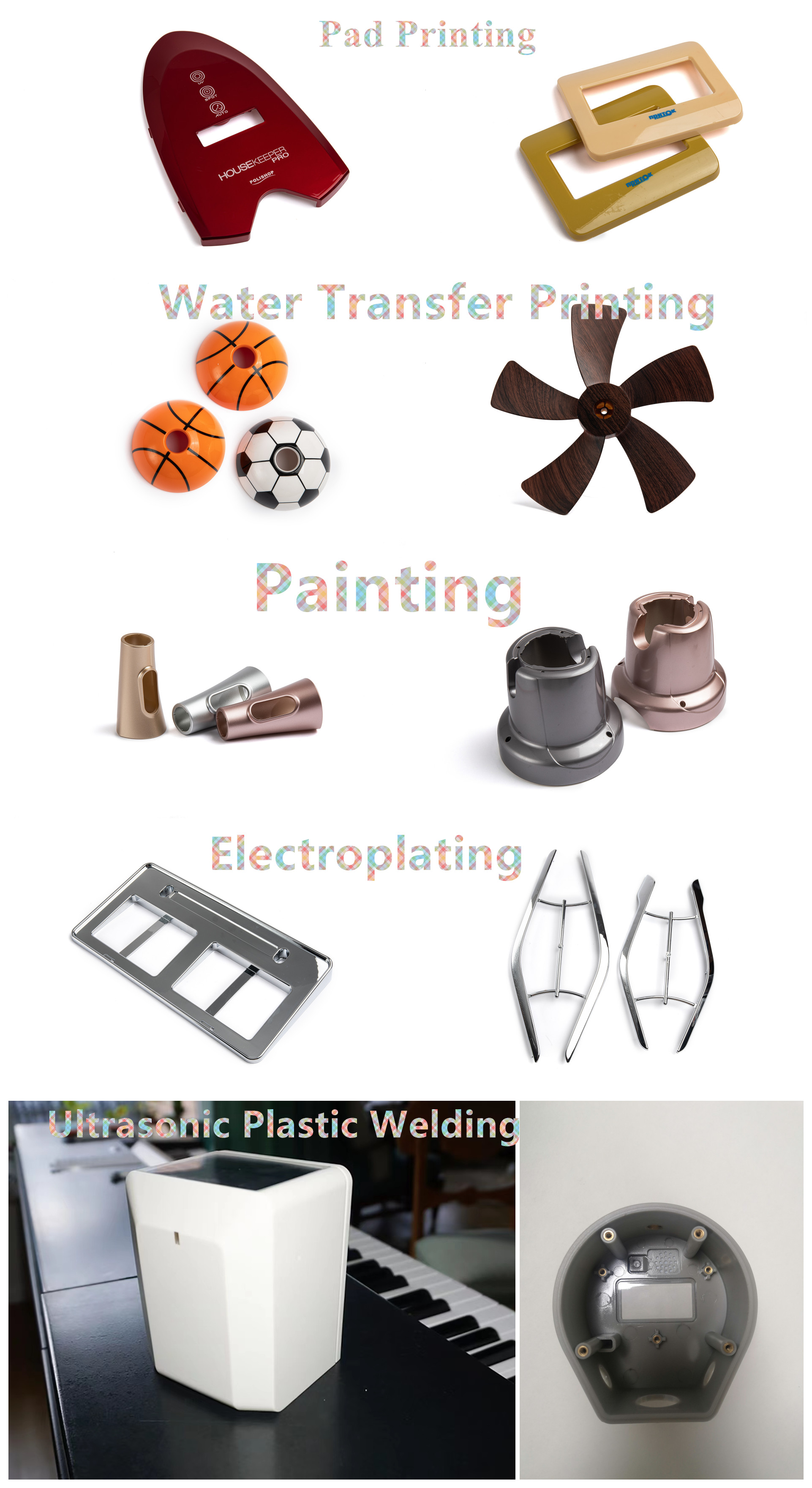

Pad Printing

Pad printing yog txheej txheem luam ntawv uas tuaj yeem hloov 2D duab / logo / ntawv mus rau 3D nto.

DejTransferPrinting

Nws tseem yog lub npe hu ua immersion printing, water transfer imaging, hydro dipping, uas yog ib txoj hauv kev siv cov ntawv luam tawm rau 3D qhov chaw.

Kev pleev xim

Glossy thiab matte ntau yam xim pleev xim yog ob qho tib si muaj los siv rau.

Electroplating

Nws yog txheej txheem tsim cov hlau txheej ntawm cov khoom siv hauv qab los ntawm kev txo cov cations ntawm cov hlau los ntawm kev siv hluav taws xob ncaj qha.

Ultrasonic Yas Vuam

Nws yog cov txheej txheem kev lag luam uas yog high-frequency ultrasonic acoustic vibrations hauv zos siv rau cov khoom ua hauj lwm raug tuav ua ke nyob rau hauv siab los tsim ib tug solid-state weld.

Txhaj Molding Solutions

Ceev ceevIlus haisMlauss:

Zoo tagnrho rau ib feem tsim validation, thov prototype los yog me me ntim ntau lawm.

√Lub sijhawm ua haujlwm ceev

√Tsis muaj MOQ thov

√Complex tsim txais

PawgProduction TxhajMlaus

Qhov zoo tshaj plaws rau cov khoom ntim loj dua, cov cuab yeej siv tau siab dua cov pwm txhaj tshuaj sai tab sis ua rau tus nqi qis dua.

√Txog li 500,000 lub voj voog ntawm pwm tua lub neej

√Ntau qib steel tooling & multi-cavity tooling

√Yuav siv tau rau kev txhaj tshuaj tsis siv neeg

Txhaj Molding Case Study