Cov khoom xyaw tseem ceeb thiab cov khoom ntawm cov yas

Cov yas sib xyaw yog txhua yam ua los ntawm cov khoom siv ntuj xws li cellulose, thee, natural gas, ntsev thiab roj crude los ntawm cov txheej txheem polymerization los yog polycondensation, thiab lawv ob leeg xav tau cov catalysts tshwj xeeb.Nyob rau hauv lub polymerization reactor, monomers xws li ethylene thiab propylene tau txuas ua ke los tsim cov saw hlau ntev.Txhua lub polymer muaj nws cov khoom, qauv thiab qhov loj me nyob ntawm ntau hom kev siv monomers.

Muaj ntau ntau hom yas, tab sis lawv tuaj yeem muab faib ua ob tsev neeg tseem ceeb polymer:

1.Thermoplastics (uas soften ntawm cua sov thiab ces harden dua nyob rau hauv txias).

2.Thermosets (uas yeej tsis soften ib zaug lawv tau molded).

Cov kev pabcuam twg peb tuaj yeem muab tau txog cov yas

Yas txhaj moulds:

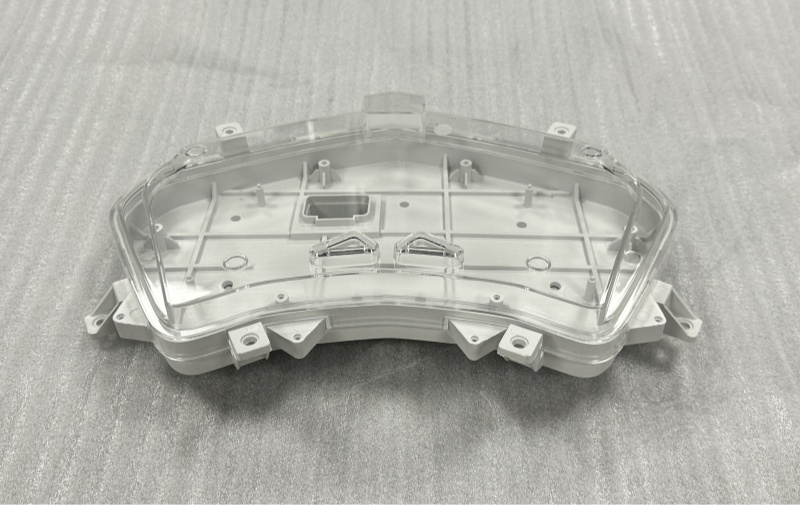

Kev txhaj tshuaj molding yog ib txoj hauv kev siv ntau tshaj plaws rau cov khoom yas thiab yog lub hauv paus ntawm RuiCheng lub peev xwm ntau lawm.Kev txhaj tshuaj molding yog txhaj cov khoom siv cua sov rau hauv cov qauv, hu ua pwm, uas tom qab ntawd txias rau hauv ib feem uas zoo, muaj zog, thiab rov ua dua.

Kev txhaj tshuaj molding yog qhov rov ua tau zoo heev, uas ua rau nws zoo rau cov hom lag luam sib xws thiab kev ntseeg tau ib feem.Qhov no kuj ua rau kev txhaj tshuaj molding tsis tshua muaj txiaj ntsig thiab raug nqi rau cov khoom ntim siab.

yog tias xaiv peb ua koj cov khoom siv yas, peb tuaj yeem muab tus nqi pheej yig tshaj plaws thiab cov khoom zoo tshaj plaws

Rapid txhaj pwm:

Kev txhaj tshuaj nrawm nrawm (RIM) yog cov txheej txheem txhaj tshuaj molding tsim rau kev tsim cov khoom me me ntawm cov khoom yas nrog lub sij hawm luv luv dua li cov txheej txheem txhaj tshuaj molding.Feem ntau, cov cuab yeej siv rau RIM yog tib yam li siv rau kev txhaj tshuaj molding ib txwm, tshwj tsis yog tias RIM txhaj tshuaj pwm yog tsim los rau kev hloov pauv sai es tsis txhob siv sijhawm ntev ntau lawm.

Overmolding:

Overmolding yog txheej txheem ntau-kauj ruam txhaj tshuaj molding qhov twg ob los yog ntau tshaj cov khoom yog molded saum ib leeg.Overmolding yog qee zaum hu ua ob-shot molding vim nws yog ob-kauj ruam txheej txheem.

Ua ntej, lub hauv paus tivthaiv (lwm yam hu ua substrate) yog molded thiab tso cai rau kho.Overmolded substrates feem ntau yog ua los ntawm yas.Tom qab ntawd, ib txheej thib ob yog molded ncaj qha rau sab saum toj ntawm thawj zaug los tsim ib qho khoom.Overmolding feem ntau yog siv los tsim cov khoom yas uas muaj cov roj hmab kov.Ob txoj kev txhaj tshuaj ntawm cov txhuam hniav, piv txwv li, muaj kev tsim cov txheej txheem rau cov yas kov thiab cov roj hmab sab saum toj (kom cov txhuam hniav kom tsis txhob ntog).

Ob xim pwm:

Ob-xim txhaj tshuaj molding yog txheej txheem tsim khoom siv thaum xa mus rau pwm ob cov ntaub ntawv / xim rau hauv ib feem yas, uas yog cov cuab yeej siv ob qho khoom lossis ob xim sib txawv rau hauv ib qho kawg yas los ntawm kev siv 2k txhaj tshuaj molding tshuab.

Kev siv cov khoom yas

Advanced plastics yog ib qho tseem ceeb rau kev tsim tsheb.Yuav luag txhua qhov zoo ntawm lub tsheb niaj hnub no - los ntawm kev nyab xeeb thiab kev ua haujlwm mus rau kev ua haujlwm zoo thiab kev zoo nkauj - tso siab rau cov yas thiab, ntau ntxiv, cov khoom siv polymer kom tau raws li cov neeg siv khoom xav tau.

Raws li Tuam Tshoj tus neeg muag khoom yas, peb kuj xyuam xim siv cov yas hauv kev lag luam tsheb thiab tsom mus rau kev tsim cov khoom yas zoo dua qub.Our cov khoom muag rau txhua qhov chaw, tshwj xeeb tshaj yog Europe Slovakia thiab Romania.

Tam sim no yas tau siv dav hauv kev lag luam kev ua si nawv, ntau yam khoom siv ntawm kev ua si nawv yog tsim los ntawm plastic.xws li cov khoom siv kis las, lub log ntawm lub tshuab ntaus pob tesniv.Rau cov khoom siv kis las no peb feem ntau siv overmoulding los tiv thaiv qhov tseem ceeb.Peb cov khoom ua si yas yog li nrov hauv Brazil, yog tias koj xav paub ntau ntxiv, thov saib peb cov ntaub ntawv lossis cov khoom lag luam hais txog kev ua si nawv yas.

Rau qhov loj, cov yas kho mob sib txawv hauv cov khoom thiab cov yam ntxwv.Vim yog cov kev cai nruj me ntsis rau cov khoom kho mob, peb cov kws kho mob siv cov yas yas kho mob rau cov ntawv kho mob tshwj xeeb, los ntawm cov cuab yeej phais mus rau cov khoom siv kho mob.Txhawm rau kom ntseeg tau tias cov khoom yas kho mob no ua tau raws li cov qauv kev kho mob, peb tau ua ntau txhiab qhov kev sim.Tam sim no cov yas kho mob siv rau kev kho mob prototypes thiab qhov chaw tuaj yeem xa cov khoom tsim nyog rau kev cuam tshuam, hnav, kub, thiab corrosion.Nyob rau tib lub sijhawm, cov khoom siv yas no tuaj yeem tswj tau qhov kev ua tau zoo tom qab ua kom tsis muaj menyuam rov qab los yog lub cev.

Qhov zoo ntawm cov khoom yas

➢ Kev tsim qauv yooj yim dua

➢ Ntau yam khoom siv

➢ Kev pom pom zoo heev.

➢ Lub sijhawm tsim khoom sai dua

➢ Zoo rov ua tau zoo thiab ua siab ntev

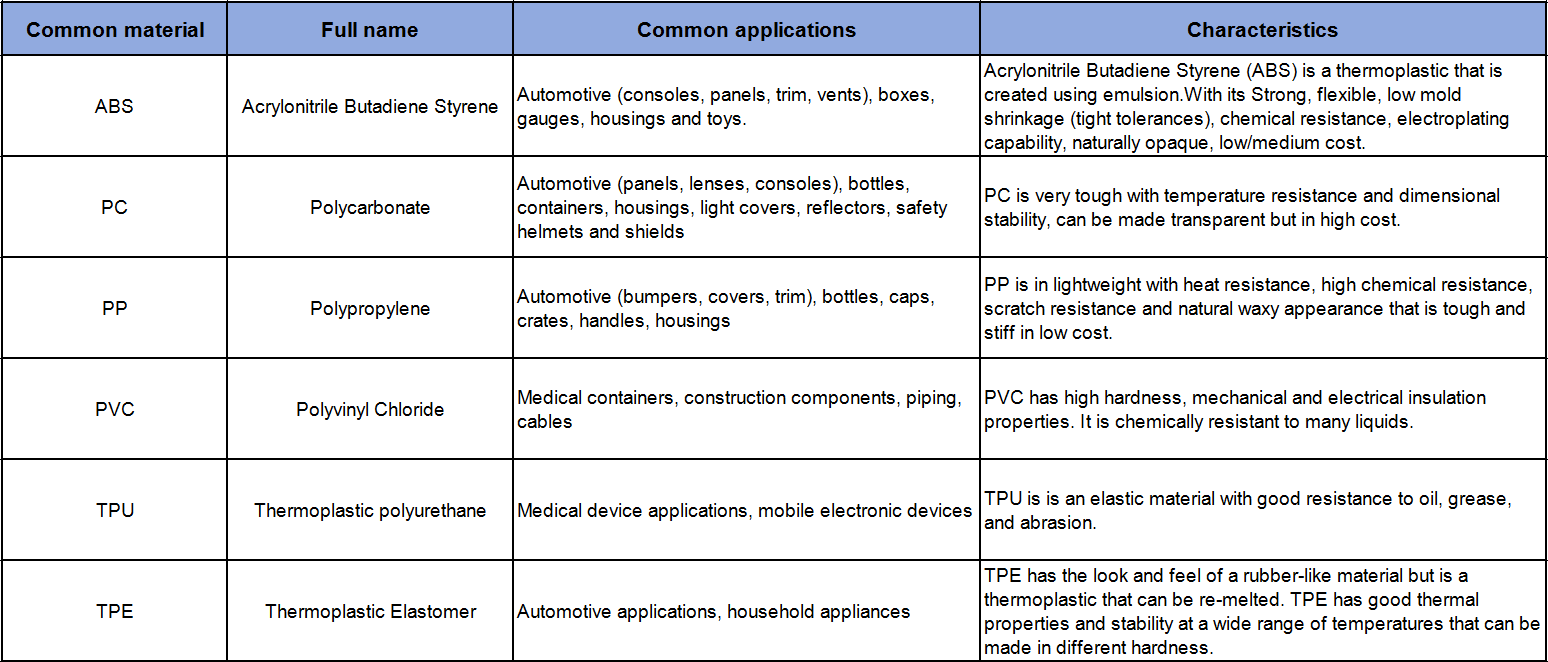

Dab tsi yas peb feem ntau siv hauv kev txhaj tshuaj

Yog xav paub ntxiv txog kev txhaj tshuaj yas yas, koj tuaj yeem ua tautiv tauj pebpab pawg muag khoom los tham txog koj daim ntawv thov tshwj xeeb.

Lub sij hawm xa tuaj: Plaub Hlis-11-2024