1.Coating Treatment: Ib qho ntawm cov txheej txheem kev kho saum npoo ntawm cov khoom siv yog txheej txheej, xws li galvanizing, npib tsib xee plating, thiab chroming.Coatings muab cov txheej txheem tiv thaiv ntawm cov hlau nto, txhim kho nws cov corrosion kuj thiab txhim kho qhov tsos.Cov coatings kuj tuaj yeem ua rau cov tawv tawv thiab hnav tsis kam ntawm cov hlau.

2.Painting Treatment: Painting yog ib txoj kev kho saum npoo ntawm cov khoom siv kho vajtse, qhov kev tiv thaiv txheej yog siv los ntawm cov xim pleev xim lossis txheej txheej rau ntawm cov hlau.Kev pleev xim tuaj yeem muab ntau yam xim thiab cov teebmeem, txhim kho cov tsos thiab muab kev ua haujlwm zoo li corrosion kuj thiab khawb tsis kam.

3.Heat Treatment: Kev kho cua sov yuav hloov cov qauv thiab cov khoom ntawm cov khoom siv kho vajtse los ntawm kev ua kom sov thiab tswj cov txheej txheem txias.Cov kev kho cua sov feem ntau muaj xws li annealing, quenching, thiab tempering.Kev kho cua sov tuaj yeem txhim kho hardness, lub zog, thiab corrosion kuj ntawm hardware kom tau raws li cov kev thov tshwj xeeb.

4.Polishing Treatment: Polishing yog txheej txheem ntawm kev ua kom cov hlau nto du thiab glossy los ntawm kev siv tshuab lossis tshuaj.Polishing tuaj yeem tshem tawm qhov tsis xws luag, oxides, thiab cov kab mob sib kis los ntawm cov khoom kho vajtse, txhim kho cov tsos thiab tactile zoo.

5.Brushing: Txhuam txhuam yog ib txoj kev siv hlau ntau siv los hloov cov tsos thiab kev ntxhib los mos ntawm cov hlau.Nws yog siv rau ntau yam hlau xws li stainless hlau, aluminium thiab tooj liab.Txhuam muab qhov tshwj xeeb zoo thiab zoo rau cov hlau los ntawm mechanically lossis chemically kho qhov saum npoo ntawm cov hlau los tsim ib qho kev ntxhib los mos los yog khawb.

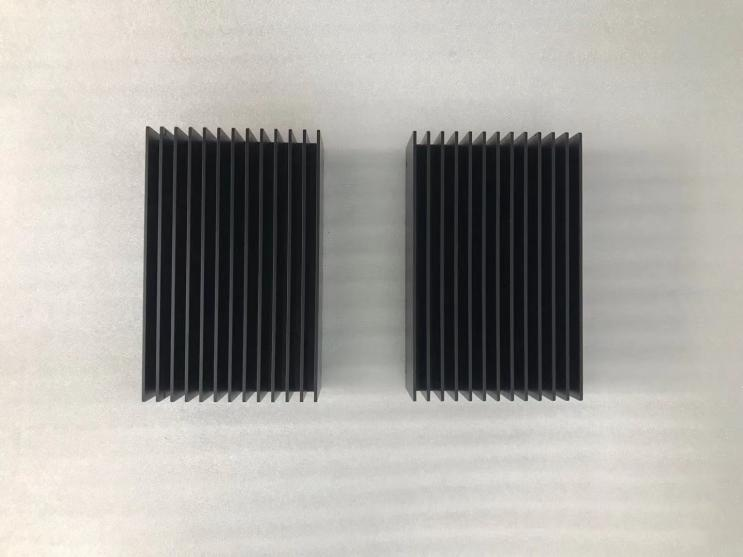

6.Anodizing: Anodizing yog ib hom kev kho deg siv rau txhuas thiab nws cov alloys.Nws koom nrog kev tsim cov txheej txheem oxide ntawm qhov chaw ntawm txhuas los ntawm cov txheej txheem electrochemical, txhim kho nws cov corrosion kuj, hardness, thiab hnav tsis kam.

7.Laser engraving: Laser engraving yog txheej txheem uas siv laser tshuab los etch nto ntawm ib yam khoom.Nws vaporizes los yog oxidizes cov khoom nyob rau saum npoo ntawm ib yam khoom los ntawm kev tsom thiab irradiation ntawm lub high-zog laser beam, uas ua rau ib tug qauv, ntawv nyeem los yog duab nyob rau hauv qhov tob los yog ntiav nyem nyem.

8.Blackening: Blackening yog kev kho saum npoo uas feem ntau siv rau cov khoom siv hlau, tshwj xeeb tshaj yog cov khoom siv hlau.Nws yog siv los ua kom cov xim tsaus thiab ua rau kom muaj kev tiv thaiv corrosion los ntawm kev tsim cov oxide dub ntawm cov hlau nto.

9.Dacromet (Dacro): Dacromet (Dacro) yog lub npe lag luam rau cov hlau tiav thiab cov txheej txheem tiv thaiv corrosion.Nws yog ib qho kev siv tshuaj tiv thaiv corrosion siab heev uas yog siv los tiv thaiv cov khoom hlau thiab hlau los ntawm corrosion thiab oxidation.

Dacromet txheej feem ntau suav nrog cov khoom hauv qab no:

Chromate-free Primer: Qhov no yog txheej primer ntawm Dacromet txheej, uas tsis muaj teeb meem chromium compounds.Lub luag haujlwm tseem ceeb ntawm primer yog muab cov adhesion zoo thiab corrosion kuj thaum muab lub hauv paus zoo rau lub tsho loj.

Corrosion-resistant Intermediate Txheej: Qhov no yog ib qho tseem ceeb ntawm Dacromet txheej.Cov txheej nruab nrab muaj ntau yam corrosion inhibitors thiab corrosion-resistant pigments uas zoo tiv thaiv corrosion thiab oxidation ntawm steel nto.

Organic Txheej: Qhov no yog txheej txheej sab nraud ntawm Dacromet txheej thiab feem ntau yog cov txheej txheem organic.Nws tsis tsuas yog muab cov xim thiab cov teebmeem zoo nkauj, tab sis kuj ua rau kom lub zog thiab khawb tsis kam ntawm txheej.

10.Sandblasting: Sandblasting, tseem hu ua sandblasting tu, sandblasting polishing, los yog pneumatic sandblasting, yog ib hom kev npaj nto siv los ntxuav, roughen, los yog txhim kho cov kev ntxhib los mos ntawm cov khoom nto.

Thaum xaiv qhov chaw kho mob rau hlau, ntau yam yuav tsum tau xav txog:

Lub hom phiaj thiab cov kev xav tau: Ua ntej, txiav txim siab koj lub hom phiaj tshwj xeeb thiab cov tseev kom muaj rau kev kho cov hlau saum npoo.Puas yog koj xav tiv thaiv cov hlau los ntawm corrosion thiab oxidation, txhim kho qhov zoo nkauj zoo nkauj, ntxiv cov teebmeem zoo nkauj, lossis txhim kho txheej adhesion?Cov kev kho mob sib txawv tau txais txiaj ntsig sib txawv raws li ntau lub hom phiaj thiab cov kev xav tau.

Hom khoom: Xav txog hom thiab yam ntxwv ntawm cov hlau.Cov hlau sib txawv, xws li steel, aluminium, tooj liab, thiab lwm yam, tej zaum yuav muaj kev hloov pauv mus rau ntau txoj kev kho deg.Qee cov hlau yuav ua rau corrosion ntau dua, thaum lwm tus yuav xav tau txoj kev kho tshwj xeeb los txhim kho adhesion.

Ib puag ncig tej yam kev mob: Coj mus rau hauv tus account ib puag ncig tej yam kev mob uas cov khoom hlau yuav raug rau.Yog hais tias cov hlau yuav raug rau ib qho chaw ntub dej, acidic, los yog corrosive ib puag ncig, xaiv txoj kev kho saum npoo nrog zoo corrosion kuj tseem ceeb heev.Yog tias cov hlau yuav siv sab nraum zoov, huab cua tsis kam thiab UV kuj tseem yog qhov tseem ceeb rau kev xav.

Kev siv nyiaj thiab nqi: Cov kev kho deg sib txawv yuav muaj cov nqi sib txawv thiab teeb meem siv.Xav txog koj cov peev nyiaj thiab cov peev txheej los xaiv ib txoj hauv kev uas haum rau koj lub peev xwm nyiaj txiag.

Feasibility thiab operability: Xav txog qhov ua tau thiab kev ua haujlwm ntawm txoj kev kho saum npoo uas tau xaiv.Qee txoj hauv kev yuav xav tau cov cuab yeej tshwj xeeb thiab kev txawj ntse, thaum lwm tus yuav yooj yim dua thiab siv tau ntau dua.Xyuas kom tseeb tias koj muaj cov cuab yeej tsim nyog, kev txawj ntse, thiab cov peev txheej, lossis tuaj yeem tau txais kev pabcuam tshaj lij.

Xav txog cov xwm txheej saum toj no, koj tuaj yeem xaiv los ntawm ntau hom kev kho hlau tsim nyog, suav nrog sandblasting, electroplating, kub-dip galvanizing, anodizing, hmoov txheej, thiab lwm yam.Yog tias koj tsis paub tseeb tias txoj kev twg haum rau koj qhov xwm txheej, koj tuaj yeem sab laj nrog peb.Xiamen Ruicheng tau ua txhua yam kev kho mob hlau nto rau ntau tus neeg koom tes thiab tau txais kev tshuaj xyuas zoo heev.Peb cov kws tshaj lij thiab kev paub tuaj yeem muab cov lus qhia ntxaws ntxaws rau koj raws li koj qhov kev xav tau tshwj xeeb.

Post lub sij hawm: Feb-23-2024