Txhaj pwmyog cov txheej txheem tseem ceeb ntawm cov khoom siv rau kev tsim khoom, kev siv cov pwm los tsim cov khoom yas, nrog rau ntau yam zoo xws li muab kev ua haujlwm zoo, yooj yim los xyuas kom zoo, tsis tshua muaj nqi ntau lawm, txhaj tshuaj pwm yog nce dav siv hauv kev tsim khoom.Raws li cov txheej txheem tseem ceeb tshaj plaws ntawm kev txhaj tshuaj molding, qhov zoo ntawm nws cov pwm ncaj qha cuam tshuam rau qhov zoo ntawm cov khoom, thaum lub sij hawm tsim cov pwm nyob rau hauv ib tug loj feem ntawm cov nqi ntawm kev lag luam.Yog li txhim kho kev pab cuam lub neej / tua lub neej ntawm kev txhaj tshuaj pwm kom txo cov nqi ntawm cov khoom yas, txhim kho kev lag luam tsim khoom thiab kev sib tw muaj feem cuam tshuam.

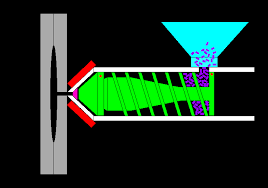

Cov txheej txheem yas txhaj tshuaj molding yog tsuas yog cov khoom siv yas hauv lub tshuab txhaj tshuaj tom qab cua sov plasticization, nyob rau hauv lub tshuab txhaj tshuaj ntsia hlau propulsion, tom qab cov yas nce mus txog qhov kub thiab txias, muaj qee qhov siab thiab ceev los ntawm lub tshuab txhaj tshuaj nozzle rau hauv pwm kab noj hniav, thiab tom qab ntawd cov pwm tom qab lub siab, cov khoom txias thiab qhib pwm thiab tau txais cov khoom yas.

Thaum lub sij hawm txhaj tshuaj molding txheej txheem, qhov saum npoo ntawm cov pwm yuav tsum tau dais lub siab thaum lub pwm kaw, lub siab ntawm cov yas yaj hauv pwm kab noj hniav thiab lub zog rub tawm thaum pwm qhib, uas lub siab ntawm cov yas yaj. ntawm kab noj hniav yog qhov tseem ceeb tshaj plaws.Nyob rau tib lub sijhawm, cov pwm yuav tsum tau khaws cia ntawm qee qhov kub thiab txias, pwm kub yuav tsum sim ua kom tiav cov kev hloov pauv, cov neeg siv khoom pwm pwm kub yuav tsum siab, uas tuaj yeem txo qhov kev sib cais ntawm cov kab, thiab cov khoom yas tawm ntawm pwm kub. yuav tsum qis.Txwv tsis pub cov khoom deformation yuav loj heev.Nyob rau hauv xws li kev ua hauj lwm tej yam kev mob, cov pwm yog raug rau ntau deformation thiab kub thiab txias qaug zog rupture, feem ntau nyob rau hauv qhov kev txiav txim ntawm kub thiab siab.

Yas nyob rau hauv tus txheej txheem ntawm kev sau cov pwm kab noj hniav, pwm tsim qhov chaw los ntawm qhov kub thiab txias siab melts scouring, ntws kev sib txhuam, nyob rau hauv cov txheej txheem ntawm cov khoom demoulding, kab noj hniav thiab core thiab yas qhov chaw nyob rau hauv cov txheej txheem ua hauj lwm yog yooj yim los tsim kev sib txhuam, ua rau nyob rau hauv lub phenomenon ntawm pwm hnav.Nyob rau tib lub sijhawm, vim yog qhov nquag qhib thiab kaw ntawm pwm, cov pwm qhia qhov chaw thiab cov pwm pwm tuaj yeem hnav thiab tsim kua muag ua rau xoob.

Nyob rau hauv cov txheej txheem molding, qee cov yas yuav decompose nyob rau hauv qhov kub thiab txias los tsim cov corrosive gases, uas yuav yooj yim corrode thiab puas rau saum npoo ntawm pwm, ua rau cov pwm puas.

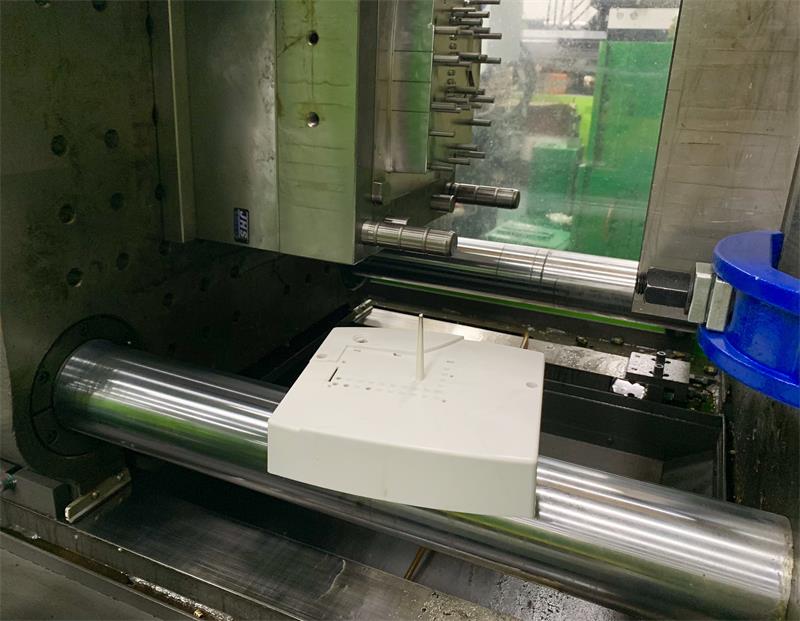

Thaum kev tsim cov pwm txhaj tshuaj mus txog ib tus lej, qhov zoo ntawm cov khoom vim kev hnav ntau dhau ntawm cov pwm tsis tuaj yeem ncav cuag qhov yuav tsum tau ua, cov khoom dhau los thiab ya ntug yog qhov hnyav, thiab cov pwm kab noj hniav thiab cov tub ntxhais tsis tuaj yeem kho, lub neej ntawm pwm tas sij hawm.Tag nrho cov khoom yas ua tiav ua ntej pwm tsis ua haujlwm tseem hu ua lub neej ntawm pwm.

Post lub sij hawm: Lub Xya hli ntuj-26-2022