Niaj hnub no peb tham txog electro-spark deposition siv nyob rau hauv cov hlau alloys, nyob rau tib lub sij hawm peb yuav tsom mus rau qhov no technology yuav ua li cas hloov cov pwm nyob rau hauv txhaj tshuaj molding tooling thiab casting pwm.

Electro-Spark Deposition yog dab tsi?

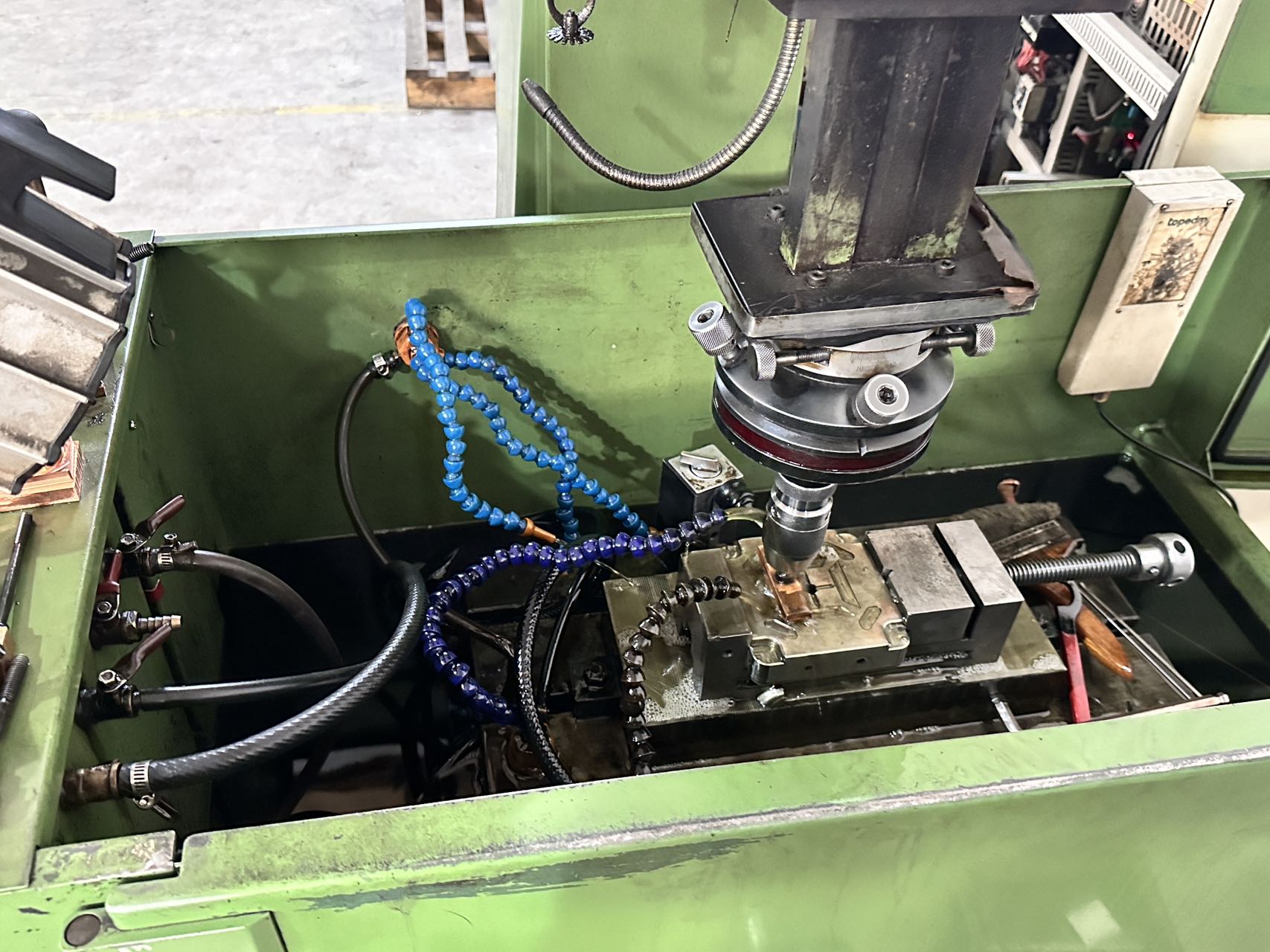

Kev kho hluav taws xob hluav taws xob, tseem hu ua Electro-discharge machining (EDM), yog cov txheej txheem tsim khoom tshwj xeeb uas suav nrog kev siv hluav taws xob tawm los tsim thiab hloov kho qhov chaw ntawm cov hlau.

Thaum kho hluav taws xob hluav taws xob, hluav taws xob tawm hluav taws xob yog tsim los ntawm cov khoom siv hluav taws xob thiab cov khoom ua haujlwm, feem ntau yog ua los ntawm cov khoom siv hluav taws xob xws li steel lossis alloys.Cov txheej txheem pib los ntawm kev tso cov electrode, feem ntau nyob rau hauv daim ntawv ntawm ib tug me me, zoo li lub cuab tam, nyob rau hauv ze ze rau lub workpiece.

Thaum muaj qhov hluav taws xob siv hluav taws xob nruab nrab ntawm cov electrode thiab cov khoom ua haujlwm, cov hluav taws xob tawm sai sai tshwm sim.Cov kev tso tawm no tsim cov cua kub hnyav, melting me me ntawm lub workpiece nto.Cov hlau molten yog sai sai quenched los ntawm dielectric kua, ua rau nws mus solidify thiab tsim me me craters los yog indentations.

ESD siv rau cov hlau alloys

Thaum lub zog capacitor raug tso tawm, qhov ncaj qha tam sim no tsim lub siab kub plasma arc nruab nrab ntawm lub taub electrode thiab cov hlau alloy workpiece.Qhov kub kub no yog nyob nruab nrab ntawm 8000 thiab 25000 ° C.Lub plasma arc ionizes lub anode thiab sai hloov cov khoom molten mus rau lub workpiece.

Qhov no ionizing anode yog pauv mus rau lub substrate ntawm luv pulses.Qhov kub-kub arc muaj xws li anode hais, lub tshav kub kwj (kub dav hlau), thiab lub plasma tsim los ntawm decomposition ntawm gases thiab reactive atoms ntawm nitrogen, oxygen, thiab carbon.Feem ntau ntawm cov cua sov yog nqa los ntawm thermal jets thiab plasma.

Vim tias cov pulses luv luv, kev hloov hluav taws xob los ntawm lub tshav dav hlau thermal thiab lwm cov roj hluav taws xob tsawg tsawg, thiab tsuas yog cov cua sov hloov mus rau hauv lub substrate yog los ntawm cov khoom me me ntawm cov khoom siv anode tso rau ntawm lub substrate.Yog li ntawd, cov pulses hloov me me ntawm cov cua sov mus rau lub substrate yam tsis tau hloov lub microstructure ntawm lub substrate.Txoj kev no yog qhov zoo dua li cov txheej txheem fusion vuam feem ntau siv los kho cov hlau tsis zoo nrog cov khoom siv hluav taws xob tsis zoo (xws li, tsis tshua muaj zog, siab hardness, liquefaction cracking).

Tsis tas li ntawd, cov txheej txheem pab tsim kom muaj kev sib raug zoo ntawm cov hlau nplaum ntawm cov substrate thiab txheej.Microalloying ntawm cov electrode yaj thiab cov substrate pib tsim cov ntshav los ntawm huab cua decomposition, carbonates, carbides thiab nitrides.

Qhov zoo

1.Precision thiab Accuracy: Electro-spark kev kho mob tso cai rau kom meej thiab meej shaping ntawm intricate cov ntsiab lus thiab complex contours ntawm hlau nto.Kev tswj cov hluav taws xob tawm hluav taws xob ua rau cov khoom siv hauv kev tswj hwm, ua rau kev tsim cov yam ntxwv zoo xws li cov qhov me me, qhov qhib, lossis indentations nrog qhov tseeb qhov tseeb.

2.Preservation of Material Integrity: Ib qho tseem ceeb ntawm kev kho hluav taws xob hluav taws xob yog nws lub peev xwm los khaws cov hardness thiab kev ncaj ncees ntawm lub workpiece.Tsis zoo li cov txheej txheem machining ib txwm muaj peev xwm ua kom muaj cua sov ntau dhau thiab ua rau tsis muaj kev hloov pauv hauv cov khoom siv, Electro-spark kev kho mob txo qis cov cheeb tsam uas cuam tshuam rau cov cua sov thiab tswj cov workpiece hardness thiab cov qauv kev ntseeg.

3.Complex Geometries: Kev kho hluav taws xob hluav taws xob ua rau kev ua haujlwm ntawm cov geometries nyuaj uas tej zaum yuav nyuaj lossis tsis tuaj yeem ua tiav nrog cov qauv machining.Nws lub peev xwm los tsim cov yam ntxwv zoo sib xws tso cai rau kev tsim cov pwm, tuag, lossis lwm yam khoom siv nrog cov contours tshwj xeeb thiab cov ntsiab lus tsis sib xws, nthuav dav cov qauv tsim.

4.No Tool Wear: Tsis zoo li cov txheej txheem machining ib txwm cuam tshuam nrog kev txiav lossis kev puas tsuaj, Electro-spark kev kho tsis cuam tshuam ncaj qha ntawm lub cuab yeej thiab cov khoom ua haujlwm.Yog li ntawd, muaj cov cuab yeej siv tsawg tsawg, ua rau lub neej ntev ntawm cov cuab yeej thiab txo cov nqi kho.

Cov ntsiab lus

Kab lus no tsuas yog qhia txog cov txheej txheem EDM hauv cov txheej txheem pwm, tsis yog tsuas yog qhia txog nws cov txheej txheem ntws, tab sis kuj qhia txog qhov zoo ntawm cov txheej txheem no.Los ntawm cov yees duab saum toj no, kuv vam tias koj tuaj yeem nkag siab cov txheej txheem kom meej meej.Yog tias koj muaj lwm yam lus nug, thov koj xav tiv taujtiv tauj peb.

Post lub sij hawm: Jun-07-2024