Rubber molding yog txheej txheem tsim khoom uas suav nrog kev tsim cov khoom siv roj hmab rau hauv cov ntawv tshwj xeeb thiab qhov ntev.Cov txheej txheem no feem ntau yog siv los tsim ntau yam khoom siv roj hmab, suav nrog cov ntsaws ruaj ruaj, gaskets, O-rings, thiab ntau yam khoom lag luam.

Muaj ntau txoj hauv kev ntawm cov roj hmab molding, nrog rau compression molding, hloov molding, txhaj tshuaj molding, thiab kua txhaj tshuaj molding.Txhua txoj kev muaj nws tus kheej zoo thiab tsim nyog rau ntau hom khoom siv roj hmab.

Roj hmab molding yog ntau yam txheej txheem uas tso cai rau kev tsim cov duab nyuaj thiab cov qauv tsim sib txawv.Nws yog dav siv nyob rau hauv kev lag luam xws li automotive, aerospace, electronics, thiab cov khoom siv kho mob.

Zuag qhia tag nrho, roj hmab molding plays lub luag haujlwm tseem ceeb hauv kev tsim khoom ntawm ntau yam khoom siv roj hmab, muab tus nqi zoo thiab muaj txiaj ntsig zoo rau kev tsim cov khoom zoo.

Niaj hnub no peb yuav xyuam xim los qhia koj txog roj hmab molding tshuab los ntawm hom tshuab, roj hmab molding zoo thiab kev siv.

RUBBER Molding yog dab tsi?

Roj hmab molding yog txheej txheem tsim khoom siv los hloov cov roj hmab uas tsis tau kho rau hauv cov khoom siv tau.Qhov no yog ua tiav los ntawm ntau yam txheej txheem, suav nrog cua sov thiab kho cov roj hmab hauv cov kab noj hniav hlau.Peb hom molding tseem ceeb yog txhaj molding, compression molding, thiab hloov molding.

Peb hom roj hmab molding tshuab

Roj hmab txhaj tshuaj molding yog ua tiav los ntawm kev txhaj tshuaj tsis muaj roj hmab rau hauv pwm.Cov roj hmab tseem nyob hauv pwm rau qee lub sijhawm kom txog thaum nws vulcanizes rau hauv nws cov duab kawg.Txawm hais tias kev txhaj tshuaj molding yog ib hom roj hmab molding, nws kuj tuaj yeem siv rau ntau yam khoom sib txawv, xws li hlau thiab iav.

Roj Hmab Compression Moulding

Roj hmab compression molding yog ua tiav los ntawm kev tso cov duab ua ntej ntawm cov roj hmab uas tsis tau kho rau hauv kab noj hniav ntawm cov pwm kub thiab tom qab ntawd siv hydraulic siab los kaw nws.Cov roj hmab tau khaws cia rau hauv lub qhov cub kom sov kom txog thaum nws yog molded rau hauv nws cov duab kawg.

Roj Hmab Hloov Molding

Roj hmab hloov molding yog ua tiav los ntawm kev thauj cov roj hmab uas tsis tau kho rau hauv lub tank hloov.Lub punch yog kaw thiab lub preform yog thawb mus rau hauv ib feem kab noj hniav los ntawm cov khiav thiab lub rooj vag system.Cov roj hmab yog tuav nyob rau hauv ib tug rhuab kab noj hniav rau ib tug tshwj xeeb npaum li cas ntawm lub sij hawm los kho nws mus rau hauv nws cov duab zaum kawg.

Khawv koob ntawm Rubber Moulding

Roj hmab molding yog ntau yam thiab muaj txiaj ntsig txheej txheem uas tso cai rau koj kom yooj yim replicate intricate cov ntsiab lus thiab tsim complex duab.Txawm hais tias koj yog tus tsim khoom lag luam, tus kws kos duab, lossis tus kws tshaj lij, kev nkag siab txog cov nuances ntawm cov roj hmab molding tuaj yeem muab koj cov haujlwm tseem ceeb.

Daim ntawv meej meej

Ib qho ntawm cov yam ntxwv zoo ntawm cov roj hmab molding yog nws lub peev xwm los tsim cov ntsiab lus me me.Qhov kev tsim tawm tiag tiag no yog qhov tseem ceeb hauv kev lag luam uas cov qauv tsim qauv tseem ceeb heev.Piv txwv suav nrog kev tsim cov hniav nyiaj hniav kub, ua cov duab me me, lossis kho hniav kho hniav.

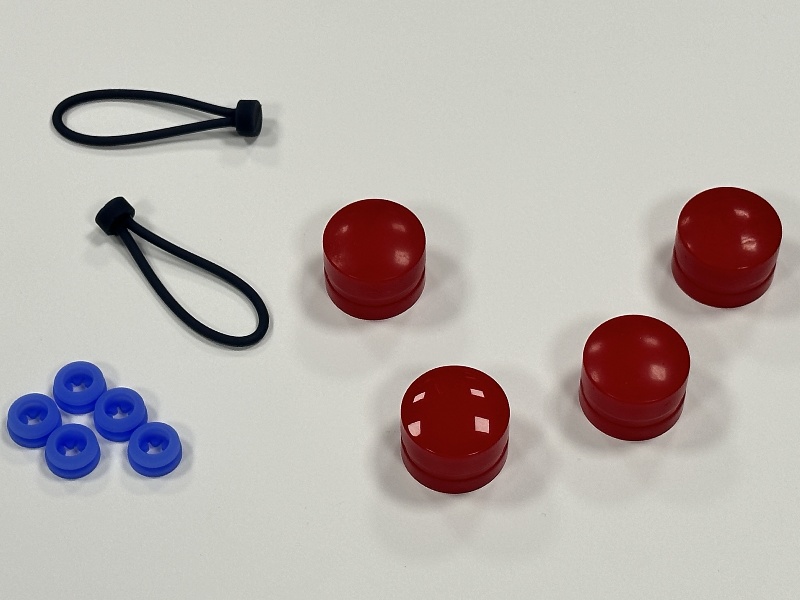

Khoom siv tau yooj yim

Roj hmab pwm tuaj yeem tsim los ntawm ntau yam khoom siv, nrog rau cov resin, yas, thiab txawmkhoom noj khoom haus qibzoo li sealing kaus mom.Qhov versatility no qhib rau lub ntiaj teb ntawm kev muaj peev xwm rau kev sim thiab kev tsim kho tshiab hauv ntau qhov chaw.

Nqi-zoo

Advanced roj hmab molding tshuab muab cov nqi tsim nyog rau kev tsim khoom me me thiab loj.Lub peev xwm los ua cov pwm meej txo cov khoom pov tseg, txuag koj cov nyiaj hauv lub sijhawm ntev.

Txuag sij hawm

Kev ceev ntawm cov txheej txheem roj hmab molding, xws li kev txhaj tshuaj molding, tuaj yeem txo lub sijhawm ntau lawm.Qhov no txhais tau tias koj cov phiaj xwm tig rov qab sai dua thiab koj tuaj yeem ua tau raws sijhawm nruj.

Tsim kev ywj pheej

Roj hmab molding tshuab muab koj txoj kev ywj pheej los sim nrog cov qauv tsim uas yuav nyuaj rau kev ua tiav los ntawm lwm txoj hauv kev.Qhov muaj tswv yim yooj yooj yim no tso cai rau koj thawb cov ciam teb ntawm koj cov haujlwm.

Roj hmab molding yog ntau yam txheej txheem uas pom daim ntawv thov nyob rau hauv ntau yam lag luam.Qee qhov kev siv ntawm cov roj hmab molding muaj xws li:

1. Automotive kev lag luam: Roj hmab molding yog siv los tsim ntau yam khoom siv hauv tsheb xws li cov ntsaws ruaj ruaj, gaskets, O-rings, hoses, thiab vibration dampeners.

2. Kev lag luam kho mob: Roj hmab molding yog siv los tsim cov khoom siv kho mob, xws li cov ntsaws ruaj ruaj, gaskets, thiab cov khoom siv roj hmab kev cai rau cov khoom siv kho mob.

3. Kev lag luam Electronics: Roj hmab molding yog siv los tsim cov npog tiv thaiv, grommets, thiab cov ntsaws ruaj ruaj rau cov khoom siv hluav taws xob thiab cov khoom siv.

4. Kev lag luam khoom siv: roj hmab molding yog siv los tsim ntau yam khoom siv, nrog rau cov khoom siv roj hmab, cov ntsaws ruaj ruaj, thiab gaskets rau cov khoom siv hauv tsev thiab cov cuab yeej siv.

5. Kev lag luam khoom kis las: Roj hmab moulding yog siv los tsim cov khoom siv rau kev ua kis las, xws li tuav, cov ntsaws ruaj ruaj, thiab kev tiv thaiv padding rau cov khoom siv.

6. Cov khoom ua si: Cov nuj nqis ua haujlwm, Roj Hmab molding ua rau cov khoom ua tau zoo thiab cov roj hmab ruaj khov thiab cov cim.

Cov no tsuas yog qee qhov piv txwv ntawm ntau daim ntawv thov ntawm cov roj hmab molding thoob plaws kev lag luam sib txawv.Cov txheej txheem muaj nuj nqis rau nws lub peev xwm los tsim cov khoom siv roj hmab tsim nrog kev ua haujlwm siab thiab ua haujlwm ntev.

Cov ntsiab lus

Kab lus no txheeb xyuas cov yam ntxwv ntawm cov roj hmab molding, nrog rau cov txheej txheem molding, uas yuav cia siab tias yuav pab koj cov khoom siv roj hmab.

Tsab xov xwm hais txog Roj Hmab Molding tshuab hom thiab nws qhov zoo, uas yuav tsum tau muaj kev paub ntau ntawm kev txhaj tshuaj molding cov chaw muag khoom thiab cov neeg muag khoom txhaj tshuaj molding khoom.

Yog tias koj muaj ib txoj haujlwm uas muaj ob txoj haujlwm no, nws raug nquahu kom paub meej tias lub Hoobkas txhaj tshuaj pwm thiab cov khoom siv tshuaj molding muaj kev paub dhau los ua cov khoom zoo sib xws los xyuas kom meej tias kev ua haujlwm zoo ntawm qhov project lossis koj tuaj yeem ua tau.tiv tauj peb, peb pawg kws tshaj lij yuav teb koj cov lus nug.

Post lub sij hawm: May-13-2024