Vim lub siab transmittance ntawm cov yas pob tshab, muaj cov kev cai nruj ntawm qhov zoo ntawm cov khoom yas, xws li tsis muaj pob, tsis muaj qauv, porosity, dawb, ntug kab, dub me ntsis, discoloration, uneven luster, thiab lwm yam. tag nrhotxhaj tshuaj moldingtxheej txheem, yuav tsum muaj nruj thiab tshwj xeeb yuav tsum tau rau raw khoom, khoom, pwm thiab txawm cov khoom tsim.

Txij li cov pob tshab yas feem ntau muaj qhov siab melting point tab sis tsis muaj peev xwm txaus, kho lub tshuab kub coefficient, kev txhaj tshuaj siab, thiab kev txhaj tshuaj nrawm kom ntseeg tau tias qhov zoo ntawm qhov chaw tuaj yeem ua rau qhov chaw txhaj tshuaj thaum txo qhov muaj peev xwm tsim kev ntxhov siab thiab ua rau deformation thiab tawg.Yog li ntawd, kev ua haujlwm nruj yuav tsum tau ua nyob rau hauv kev npaj cov khoom siv raw, cov khoom siv xws li cov khoom siv yas molding ntshiab thiab kev txhaj tshuaj pwm, txheej txheem txhaj tshuaj molding thiab raw khoom tuav cov khoom.Yuav ua li cas thiaj ua kom cov yas pob tshab kom meej meej?Hauv qab no yog qee yam uas koj yuav tsum paub:

1. Kev npaj thiab ziab ntawm cov khoom siv raw

Txij li thaum me ntsis impurity nyob rau hauv cov yas yuav cuam tshuam rau lub pob tshab ntawm cov khoom, cov khoom yuav tsum tau muab kaw kom zoo thaum lub sij hawm cia, kev thauj mus los thiab pub mis kom paub tseeb tias cov khoom yog huv si, tshwj xeeb tshaj yog cov raw khoom yog yooj yim deteriorate tom qab cua sov.Muaj dej noo me ntsis, yog li nws yuav tsum tau qhuav hauv lub hnub.Tsis tas li ntawd, lub hopper yuav tsum tau qhuav thaum pub mis.Tsis tas li ntawd, cov huab cua tuaj yuav tsum tau lim thiab dehumidified thaum lub sij hawm ziab kom paub tseeb tias nws tsis paug cov khoom siv raw.

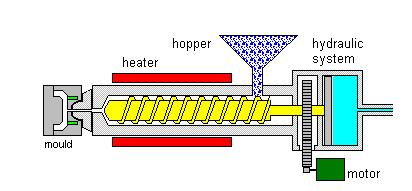

2.Kev ntxuav lub thoob, ntsia hlau thiab lwm yam khoom siv

Txhawm rau tiv thaiv kev kis kab mob ntawm cov khoom siv raw thiab zais cov khoom seem lossis impurities hauv qhov chaw ntawm cov khoom siv, tshwj xeeb tshaj yog cov resin nrog cov thermal stability tsis zoo, cov yas ntawm cov pwm thiab cov ntsia hlau ntawm lub tshuab yuav tsum tau muab ntxuav nrog cov tshuaj ntxuav kom huv si kom tshem tawm cov impurities, los yog nyob rau hauv cov pwm. tsis muaj cov ntsia hlau ntxuav, siv PE, PS thiab lwm yam resins los ntxuav cov ntsia hlau.Thaum dheev kaw lawm, txhawm rau tiv thaiv kom tsis txhob decomposition ntawm raw cov ntaub ntawv ntawm qhov kub thiab txias rau lub sijhawm ntev, qhov kub ntawm lub tshuab ziab khaub ncaws thiab lub thoob yuav tsum tau txo, xws li PC, PMMA chim kub yuav tsum qis dua 160 degrees (qhov kub ntawm lub hopper yuav tsum. txo kom qis dua 100 degrees PC).

3.Kev txhaj tshuaj pwm tsim yuav tsum tau xyuam xim rau cov ntsiab lus hauv qab no (nrog rau cov khoom tsim)

Cov ntsiab lus hauv qab no yuav tsum raug sau tseg thaum tsim cov pwm txhaj tshuaj los tiv thaiv cov yas molding tsis zoo, qhov chaw tsis zoo thiab kev puas tsuaj tshwm sim los ntawm qhov tsis zoo rov qab los yog tsis sib xws.

a) Phab ntsa thickness yuav tsum yog tas li raws li qhov ua tau thiab cov pwm txoj kab nqes yuav tsum loj npaum li qhov ua tau.

b) Kev hloov pauv yuav tsum maj mam thiab du kom tsis txhob muaj cov kab ntse thiab cov npoo ntse, tshwj xeeb tshaj yog rau cov khoom siv pc, thiab yuav tsum tsis muaj qhov khoob.

c) Rooj vag: Tus khiav yuav tsum dav thiab luv li sai tau, thiab qhov chaw ntawm lub rooj vag yuav tsum yog raws li cov txheej txheem shrinkage.Cov khoom txias txias yog xav tau yog tias tsim nyog.

d) Txhaj pwm nto yuav tsum du nrog tsawg roughness (max Ra0.8)

e) Tus naj npawb ntawm qhov venting thiab qhov tso pa tawm yuav tsum txaus kom tso pa tawm ntawm huab cua thiab roj los ntawm cov yaj.

f) Phab ntsa tuab yuav tsum tsis txhob nyias dhau, tshwj tsis yog cov khoom siv PET, feem ntau tsis pub tsawg dua 1 hli.

Tham nrog peb txog koj qhov project tshiab, kev sab laj dawb thiab dawb DFM

Post lub sij hawm: Nov-01-2022