Ruicheng yog tus kws tshaj lij hauv kev tsim cov tshuaj molding kev lag luam.Peb cov txheej txheem txhaj tshuaj molding ua tau zoo thiab raug tso cai rau peb rau cov khoom lag luam ntawm cov khoom zoo heev thiab koj tuaj yeem suav rau qhov project los kho cov khoom yas rau koj tus kheej.Peb muaj peev xwm ua tau raws li txhua yam kev lag luam yas hauv cov khoom siv, qhov ntau thiab tsawg, cov duab, kam rau ua, thiab lwm yam.

Common industrial yas khoom

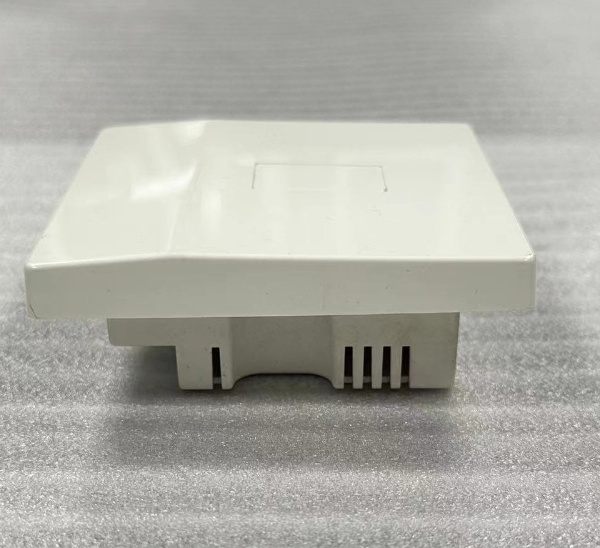

Cov khoom no yog Standard Smart WIFI Kov Lub Teeb Hloov Vaj Tsev ua los ntawm cov khoom siv yas thiab ua raws li tus qauv tshiab Asmeskas.

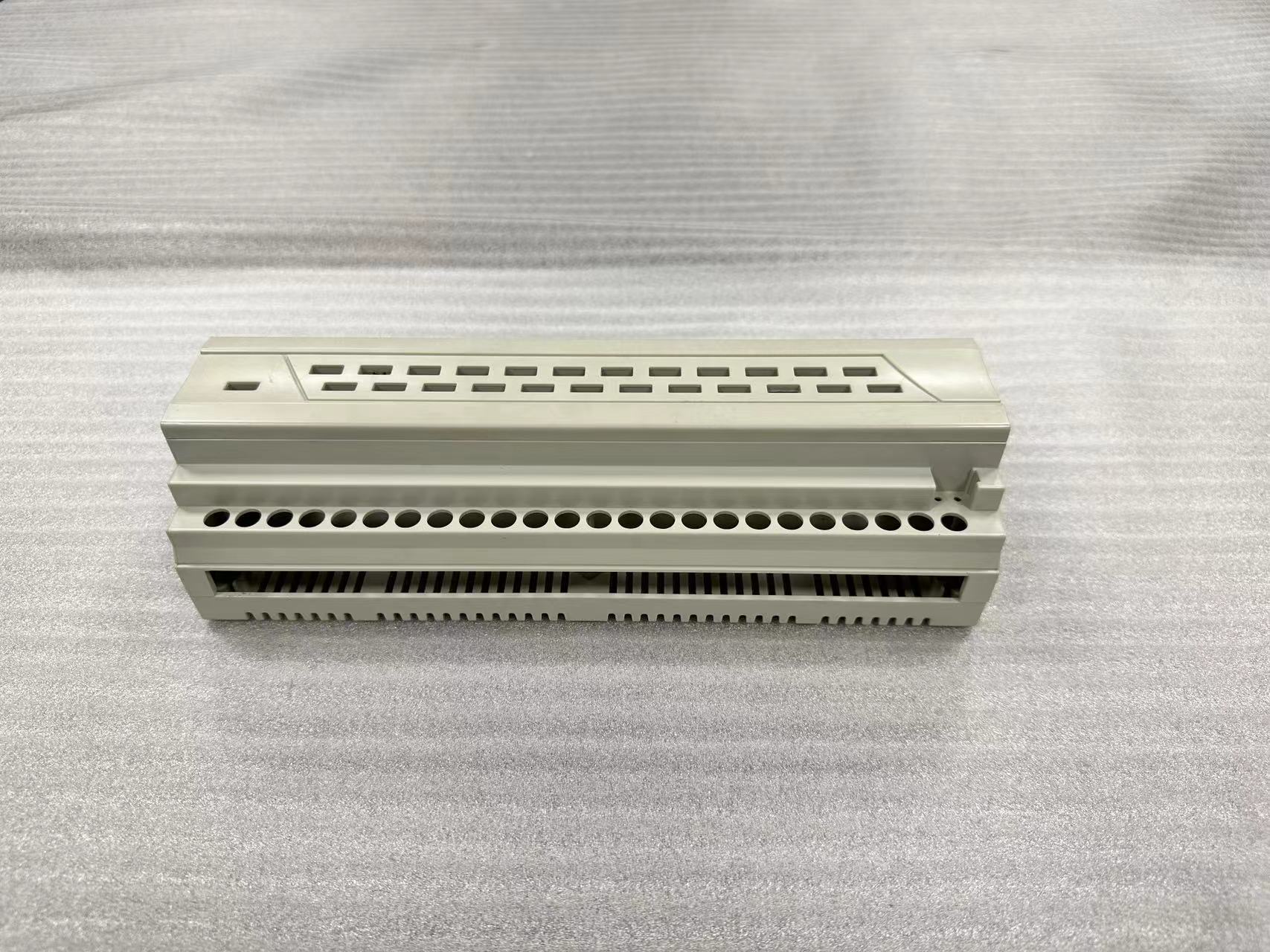

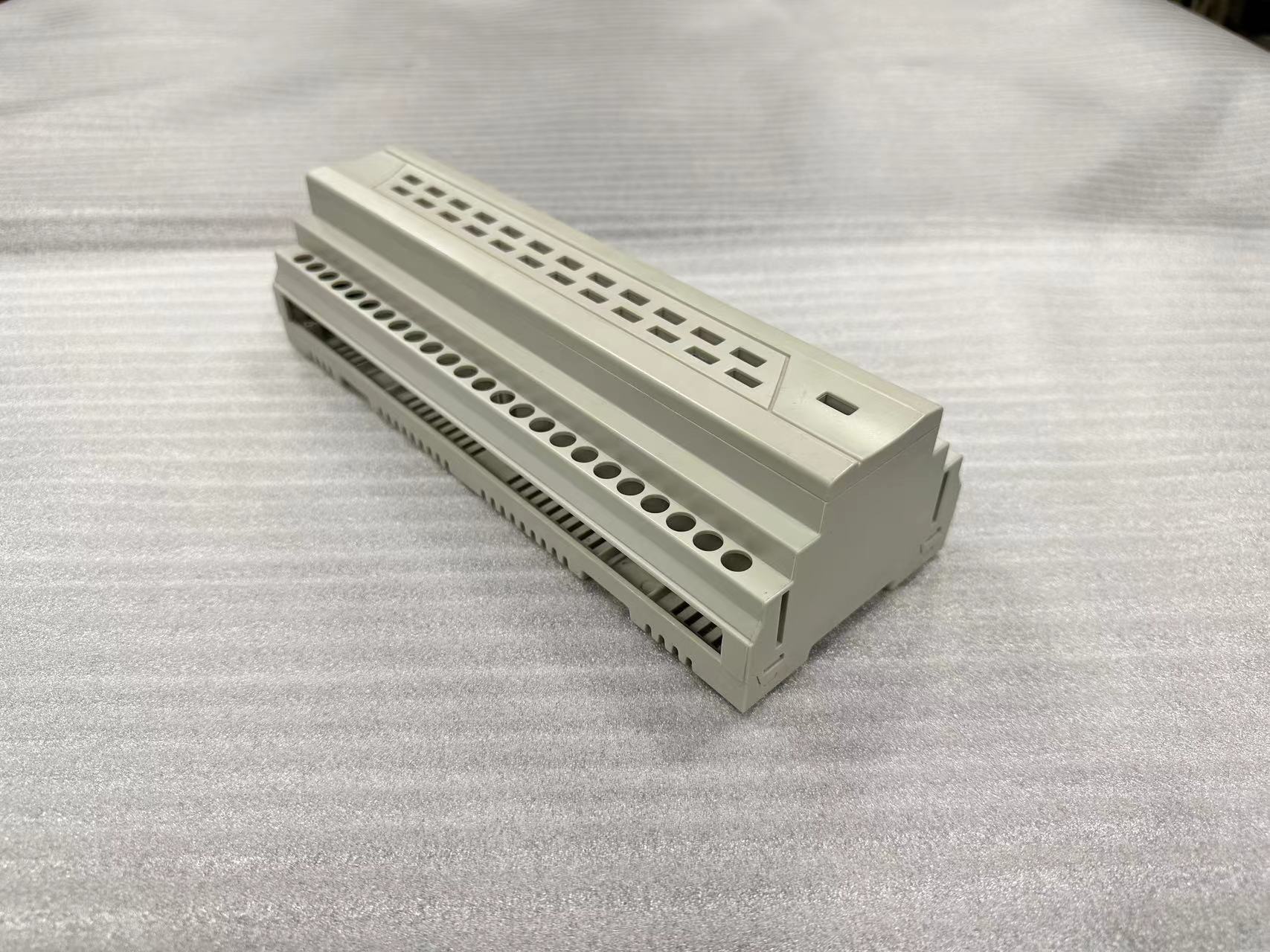

Customized Industrial Plastic Parts nrog zoo waterproof thiab UV tsis kam, uas ua rau cov khoom no ua haujlwm zoo nyob rau hauv ib puag ncig sab nraum zoov.

Ua los ntawm 100% nkauj xwb cov khoom siv yas, peb yuav tswj xyuas nruj zoo thaum lub sij hawm txhaj tshuaj molding txheej txheem, thiab ua cov kev soj ntsuam zoo thiab sib dhos tib lub sijhawm.Thaum kawg, peb yuav xa tuaj rau koj hauv peb cov khoom zoo.

4.Plastic Overmold Inserts Connector

Qhov no customized industrial charging connector yog tsim rau cov khoom siv hluav taws xob txhawb nqa.Nws tuaj yeem muab kev lav lav rau koj cov khoom siv thiab ua kom yooj yim rau koj siv.

Yam khoom twg koj tuaj yeem xaiv los ua cov khoom lag luam yas

ABS:

Acrylonitrile Butadiene Styrene (ABS) yog ib qho thermoplastic uas yog tsim los ntawm emulsion.Nrog rau nws cov Strong, saj zawg zog, tsis tshua muaj pwm shrinkage (nruj tolerances), tshuaj tsis kam, electroplating muaj peev xwm, ib txwm opaque, tsawg / nruab nrab nqi.

PAB 66:

PA66 yog ib qho ntawm cov nylon, nws muaj tib lub cim zoo li nylon, feem ntau siv rau hauv tes, levers, tsev me me, zip ties & iav, bushings.

PC

PC yog tawv heev nrog kub tsis kam thiab qhov ntev stability, tuaj yeem ua pob tshab tab sis tus nqi siab.

PP

PP yog nyob rau hauv lub teeb yuag nrog kub tsis kam, siab tshuaj tsis kam, khawb kuj thiab ntuj waxy tsos uas yog tawv thiab tawv nyob rau hauv tus nqi qis.

TPU:

TPU yog cov khoom siv elastic nrog zoo tiv taus roj, roj, thiab puas.

Cov txheej txheem ntawm kev lag luam yas khoom

Txhaj tshuaj molding yog txheej txheem tsim khoom siv rau kev tsim cov khoom yas zoo ib yam.Nws yog ib txoj hauv kev ntawm cov yas txhaj tshuaj uas cov yas molten tau muab tso rau hauv pwm los tsim ib feem ntawm cov pwm kab noj hniav, tsim kom muaj lub cev sawv cev ntawm cov qauv yas.

Kev siv cov tshuab txhaj tshuaj molding los tsim cov khoom lag luam tuaj yeem ua tiav ntau lawm, uas tuaj yeem txo cov nqi rau cov lag luam, txo cov neeg siv khoom xa tuaj, thiab tsim cov khoom zoo.

Tsis tas li ntawd, txhaj tshuaj molded qhov chaw ua los ntawm kev txhaj tshuaj muaj kev ruaj ntseg zoo heev thiab lawv cov khoom seem tuaj yeem rov ua dua tshiab, pab tshem tawm cov khib nyiab.

Overmolding

Overmolding yog txheej txheem tsim khoom uas ib qho (polymer) cov khoom yog molded los yog cam khwb cia rau lwm yam khoom uas tej zaum yuav yog composite, hlau, los yog polymer nyob rau hauv cov xwm.Qhov tshwm sim yog ib qho, sib xyaw ua ke ntawm ob cov ntaub ntawv uas feem ntau muaj cov haujlwm sib txawv hauv qhov sib koom ua ke.Daim ntawv thov ntawm cov txheej txheem no ntawm cov khoom siv yas muaj ntau heev.Silicone feem ntau yog coated rau ntawm cov khoom yas kom tsis txhob ntog, xws li txhuam hniav, hammers, hluav taws xob xyaum, thiab lwm yam. Yog hais tias nws yog siv rau cov vaj tsev ntawm cov khoom siv hluav taws xob, feem ntau yog rau rwb thaiv tsev.

Overmolding thiab txhaj tshuaj molding yog cov txheej txheem zoo tib yam siv los tsim (feem ntau) cov khoom yas.Lawv txawv tsuas yog nyob rau hauv hais tias tus txheej txheem overmolding yog ib tug thib ob ua hauj lwm.

Ua ntej peb pib, peb xav kom koj xa cov duab 3d thiab cov cai rau peb.Cov kws tshaj lij yuav tshuaj xyuas qhov project no, ntsuas nws cov qauv thiab qhov ntev los tham thiab txiav txim siab yuav tsim cov pwm li cas (xws li lub qhov rooj txhaj tshuaj, pins, lub kaum sab xis thiab lwm yam)

Qhov thib ob, peb cov neeg ua haujlwm yuav suav cov yam ntxwv ntawm koj cov khoom los teeb tsa lub tshuab txhaj tshuaj.Thaum lub cuab yeej kaw, qhia qhov pib ntawm kev txhaj tshuaj molding voj voog.

Cov granules polymer yuav qhuav thiab muab tso rau hauv lub hopper, ces lawv muab tso rau hauv lub thoob, qhov chaw uas lawv ib txhij rhuab, sib tov thiab tsiv mus rau lub pwm los ntawm ib tug sib txawv pitch ntsia hlau.Lub geometry ntawm cov ntsia hlau thiab lub thoob yog optimized los pab txhim kho lub siab mus rau qhov tseeb theem thiab yaj cov khoom.

Tom qab sau cov pwm kab noj hniav nrog yas, nws yuav tsum tau tso cai kom txias.Dej circulated feem ntau yog ib txoj hauv kev tseem ceeb los ua kom qhov kub thiab txias tsis tu ncua raws li cov khoom hardens.

Thaum cov khoom txias txias, nws rov ua kom muaj zog thiab siv cov pwm pwm.Thaum kawg, cov pwm qhib thiab cov khoom tau raug thawb tawm los ntawm ejector pins.Cov pwm tom qab ntawd kaw thiab cov txheej txheem rov ua dua.

Cov khoom tiav yuav raug ntim los ntawm kev siv lub hnab yas thiab muab tso rau hauv thawv.Yog tias koj muaj kev ntim tshwj xeeb, peb kuj tuaj yeem kho raws li qhov xav tau ntawm cov neeg siv khoom .Yog li ntawd txhua yam khoom yuav raug xa mus rau qhov zoo.

Yog xav paub ntxiv txog kev txhaj tshuaj yas yaslwm cov khoom lag luamkoj ua tau tiv tauj pebpab pawg muag khoom los tham txog koj daim ntawv thov tshwj xeeb.

Lub sij hawm xa tuaj: Plaub Hlis-15-2024