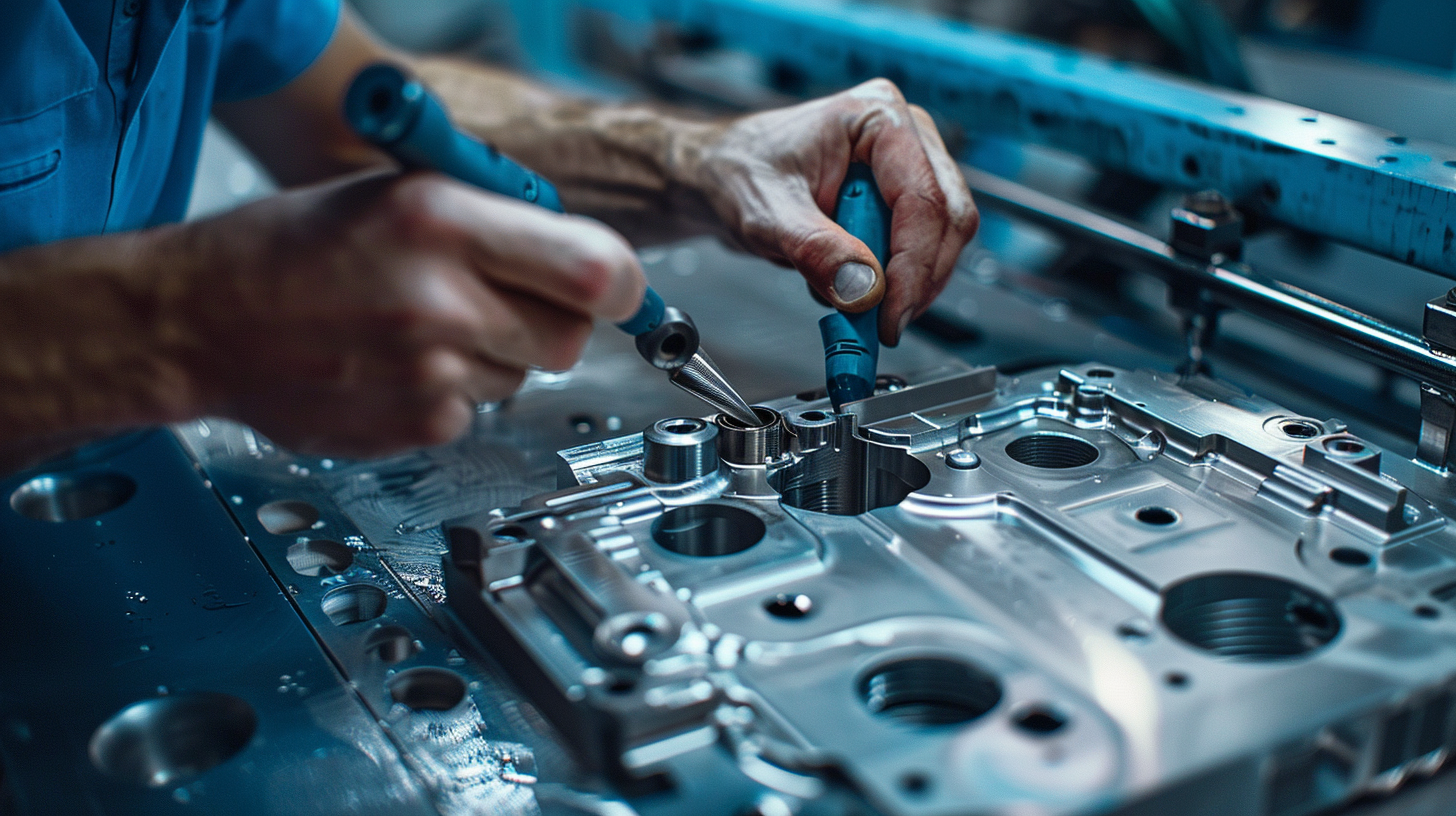

Kev txhaj tshuaj pwm yog qhov tseem ceeb hauv cov txheej txheem tsim khoom, tshwj xeeb tshaj yog rau kev tsim cov khoom yas.Lub durability thiab lifespan ntawm cov pwm no ncaj qha cuam tshuam rau kev tsim khoom thiab cov nqi.Lub pwm tuav zoo tuaj yeem tsim ntau pua txhiab qhov chaw, ua rau pwm lub neej yog qhov tseem ceeb rau cov tuam txhab.

Cov yam ntxwv cuam tshuam rau pwm lub neej

Ntau yam cuam tshuam rau lub neej ntawmtxhaj tshuaj pwm:

1.Material Quality: Cov pwm zoo steel kav ntev dua thiab tiv taus hnav zoo dua li cov khoom siv softer.Ntawm peb lub tuam txhab, peb siv cov qib high-qib steel los xyuas kom meej pwm ntev thiab kav ntev.

2.Design thiab Engineering: Tsim kom zoo kom paub meej tias txawm tias muaj kev ntxhov siab thiab muaj cov yam ntxwv zoo li cov cua txias kom ntev pwm lub neej.Peb pab neeg tsim kev paub dhau los muab cov kev daws teeb meem zoo los txhim kho pwm kev ua haujlwm.

3.Processing Parameters: Optimized txhaj tshuaj siab, kub, thiab lub voj voog lub sij hawm tiv thaiv kev hnav ntau dhau.Peb cov cuab yeej txhaj tshuaj molding siab heev tso cai rau kev tswj xyuas cov kev txwv no, kom ntseeg tau tias kev ua haujlwm pwm zoo.

Hom Plastic Resin: Lub abrasiveness thiab corrosiveness ntawm cov yas resin siv tuaj yeem cuam tshuam pwm ntev.Qee cov resins ua rau hnav ntau dua li lwm tus.Peb xaiv cov ntaub ntawv tsim nyog raws li qhov xav tau ntau lawm los txo cov pwm hnav.

Cov tswv yim tu

Kev tuav cov pwm muaj xws li:

1.Regular Inspections: Thaum ntxov ntawm cov teeb meem zoo li cov kab nrib pleb lossis corrosion tiv thaiv cov teeb meem loj.Peb muaj cov txheej txheem tshuaj xyuas kom ntseeg tau tias txhua tus pwm tseem nyob hauv qhov zoo tshaj plaws.

2. Kev Tu Kom Zoo: Siv cov tshuaj ntxuav kom tsim nyog kom tshem tawm cov khoom seem uas tsis ua rau pwm puas.Peb cov khoom siv tu thiab cov neeg ua haujlwm ua haujlwm kom muaj kev nyab xeeb thiab ua haujlwm zoo.

3.Lubrication: Lub lubrication kom zoo ntawm cov khoom txav yuav txo tau kev sib txhuam thiab hnav.Peb siv cov roj nplua nyeem zoo los xyuas kom meej cov pwm ua haujlwm zoo.

Cia Lub Sijhawm: Khaws cov pwm hauv qhov chaw huv, qhuav kom tsis txhob xeb thiab xeb.Peb cov chaw khaws khoom nruj me ntsis tswj xyuas kom cov pwm muaj kev tiv thaiv los ntawm ib puag ncig.

Kev lag luam Standards

Peb nruj me ntsis ua raws li cov qauv thoob ntiaj teb xws li ISO 9001, ua kom cov txheej txheem tsim tau zoo, suav nrog kev kho pwm thiab kev tswj xyuas kom zoo.Tsis tu ncua calibration ntawm kev txhaj tshuaj molding tshuab pab tswj kev ua haujlwm tsis zoo, txo qhov kev pheej hmoo ntawm pwm puas.

Xaus

Kev tuav cov pwm txhaj tshuaj yog qhov tseem ceeb rau kev tsim khoom kom zoo thiab raug nqi.Kev nkag siab txog yam uas cuam tshuam rau pwm lub neej thiab ua raws li kev saib xyuas zoo tuaj yeem ua rau pwm kev ua neej ntev tshaj plaws thiab ua kom cov khoom ua tau zoo.Nrog cov ntaub ntawv zoo, pab pawg tsim qauv, cov cuab yeej siv siab heev, thiab kev tswj hwm nruj, peb lub tuam txhab muab cov kev daws teeb meem zoo tshaj plaws los pab peb cov neeg siv khoom ua tiav lawv cov hom phiaj tsim khoom.Yog tias koj muaj ib qhov project xav tau, thov koj xav tias dawb rautiv tauj peb, peb yuav hu rau 24 teev ib hnub twg

Lub sij hawm xa tuaj: Plaub Hlis-01-2024