Tuag casting yog txheej txheem hlau casting nyob rau hauv uas molten hlau, feem ntau yog ib tug non-ferrous alloy xws li txhuas, zinc, los yog magnesium, yog txhaj nyob rau hauv lub siab mus rau hauv ib tug reusable steel pwm, hu ua tuag.Cov tuag yog tsim los tsim cov duab uas xav tau ntawm cov khoom kawg.

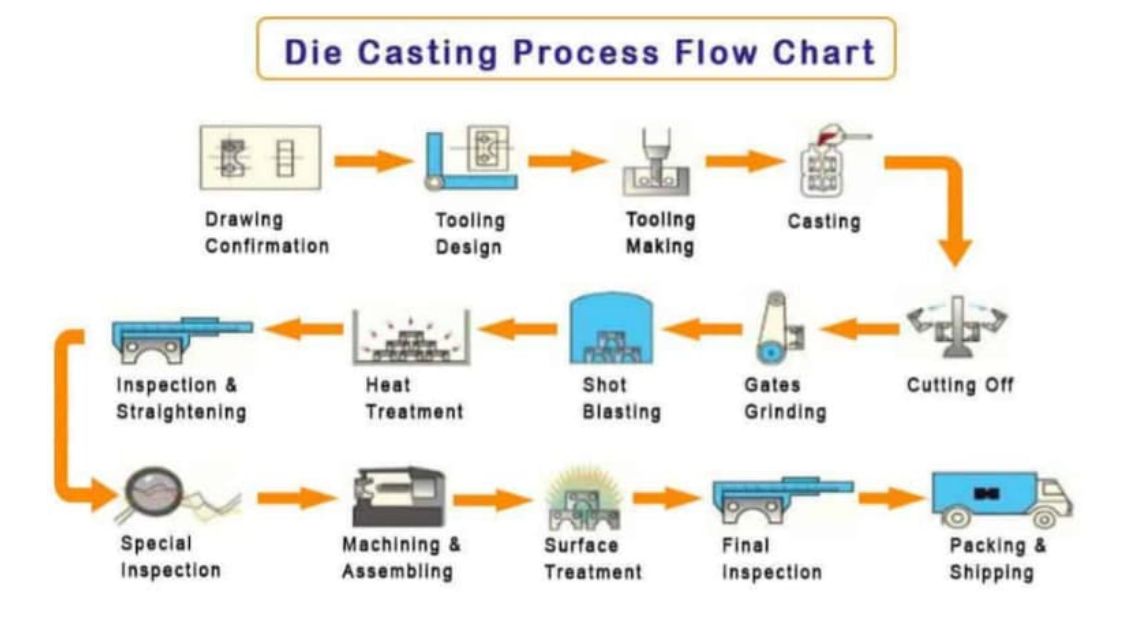

Dab tsi yog cov txheej txheem ntawm kev tuag casting?

① Kev Npaj Tuag: Cov tuag, tseem hu ua pwm, yog npaj rau txheej txheem casting.Cov tuag muaj ob halves, qhov ruaj ib nrab (npog tuag) thiab ib nrab txav tau (ejector tuag), uas tsim cov duab xav tau ntawm cov khoom kawg.

②Melting hlau: Cov hlau uas tsis yog-ferrous xaiv, xws li txhuas, zinc, los yog magnesium, yog melted nyob rau hauv lub cub tawg kub.Cov hlau molten ncav cuag qhov xav tau kub rau casting.

③ Txhaj tshuaj: Cov hlau molten yog txhaj rau hauv qhov tuag ntawm kev kub siab.Lub piston los yog plunger yuam cov hlau molten mus rau hauv qhov tuag kab noj hniav los ntawm ib tug sprue, khiav, thiab rooj vag system.Lub siab pab sau cov pwm kom tiav thiab xyuas kom meej tias cov duab xav tau tiav.

④Solidification: Thaum cov hlau molten raug txhaj rau hauv qhov tuag, nws sai sai txias thiab solidifies nyob rau hauv lub tuag kab noj hniav.Cov txheej txheem cua txias yog ua tib zoo tswj xyuas kom cov hlau solidifies uniformly thiab tsis muaj teeb meem.

⑤ Ejection: Tom qab cov hlau tau solidified thiab txias txaus, cov tuag halves tau qhib, thiab cov casting, los yog tuag casting, yog ejected ntawm lub tuag kab noj hniav.Ejection pins lossis ejector daim hlau pab thawb lub casting tawm ntawm qhov tuag.

⑥ Trimming thiab Finishing: Lub ejected tuag casting tej zaum yuav muaj ntau yam khoom, hu ua flash, nyob ib ncig ntawm nws cov npoo.Cov khoom siv ntau dhau no raug txiav tawm kom ua tiav qhov kawg xav tau zoo.Ntxiv cov txheej txheem tiav xws li machining, sanding, lossis polishing tuaj yeem ua kom zoo dua qhov chaw thiab qhov tseeb ntawm qhov casting.

⑦ Kev Kho Mob Tom Qab: Nyob ntawm cov kev cai tshwj xeeb thiab daim ntawv thov ntawm kev tuag casting, cov txheej txheem tom qab kho ntxiv tuaj yeem ua tiav.Cov no tuaj yeem suav nrog kev kho cua sov, txheej txheej, pleev xim, lossis lwm yam uas yuav tsum tau ua tiav los txhim kho cov khoom lossis cov tsos ntawm casting.

Yuav ua li cas xaiv cov txheej txheem tuag casting raws li qhov tseeb?

Kev xaiv cov txheej txheem tuag casting tsim nyog nyob ntawm ob peb yam thiab kev xav txog qhov tseeb ntawm qhov xwm txheej.Nov yog qee cov ntsiab lus tseem ceeb los xav txog thaum xaiv cov txheej txheem tuag casting:

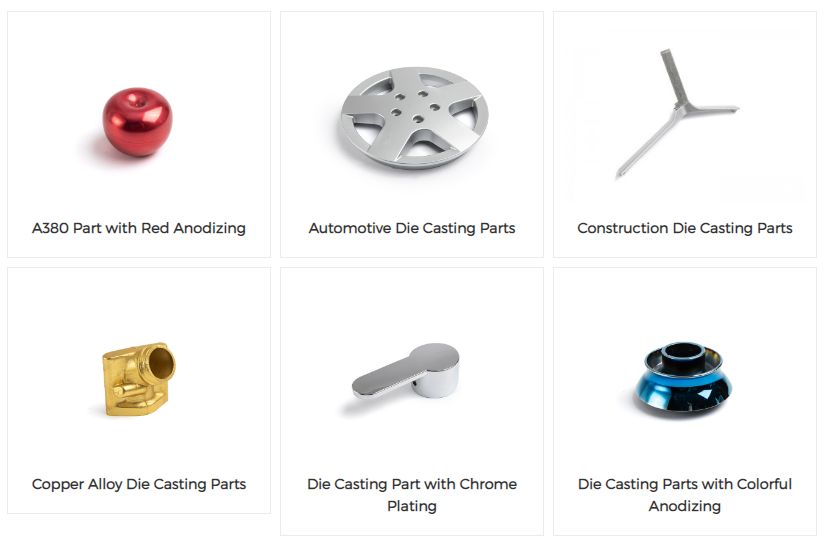

Khoom siv:Txheeb xyuas hom hlau los yog alloy siv rau kev casting.Cov hlau sib txawv muaj cov khoom sib txawv thiab cov yam ntxwv, xws li qhov kub thiab txias, fluidity, thiab shrinkage tus nqi.Xav txog cov kev cai tshwj xeeb ntawm ib feem lossis cov khoom, xws li lub zog, qhov hnyav, kev tiv thaiv corrosion, thiab thermal conductivity, thiab xaiv cov txheej txheem tuag casting uas tsim nyog rau cov khoom xaiv.

Complexity ntawm Part:Ntsuas qhov nyuaj ntawm ib feem lossis cov khoom tsim los.Txiav txim siab yog tias nws muaj cov duab zoo sib xws, cov phab ntsa nyias, undercuts, lossis cov yam ntxwv sab hauv.Qee cov txheej txheem tuag casting, xws li high-pressure tuag casting (HPDC) lossis ntau qhov swb tuag casting, yog qhov zoo dua rau kev tsim cov khoom siv nrog nruj, thaum lwm tus yuav tsim nyog rau cov qauv yooj yim dua.

Ntau lawm ntim:Xav txog qhov yuav tsum tau ntim ntau lawm.Cov txheej txheem tuag casting tuaj yeem raug cais rau hauv high-pressure tuag casting (HPDC) rau high-volume ntau lawm thiab low-pressure tuag casting (LPDC) lossis lub ntiajteb txawj nqus tuag casting rau qis ntim.HPDC feem ntau ua tau zoo dua thiab raug nqi rau kev tsim khoom loj, thaum LPDC thiab lub ntiajteb txawj nqus tuag casting yog qhov zoo dua rau kev ua haujlwm me me lossis kev tsim qauv.

Surface Finish thiab Precision:Ntsuam xyuas qhov xav tau nto tiav thiab qhov yuav tsum tau muaj qhov tseeb ntawm qhov.Qee cov txheej txheem tuag casting, xws li nyem casting los yog lub tshuab nqus tsev tuag casting, tuaj yeem muab kev txhim kho saum npoo thiab ua kom nruj dua piv rau cov tsoos high-pressure tuag casting.Cov txheej txheem no tej zaum yuav nyiam rau qhov chaw uas yuav tsum tau tshwj xeeb nto smoothness los yog meej qhov ntev.

Tooling thiab khoom siv:Txheeb xyuas qhov muaj cov cuab yeej thiab cov khoom siv uas xav tau rau cov txheej txheem tuag casting.Qee cov txheej txheem yuav xav tau cov tshuab tshwj xeeb, xws li cov tshuab hluav taws xob siab tuag casting lossis cov tshuab qis qis.Xav txog tus nqi, lub sijhawm ua haujlwm, thiab qhov ua tau ntawm kev tau txais lossis hloov kho cov cuab yeej thiab cov cuab yeej tsim nyog rau cov txheej txheem xaiv.

Nqi thiab Efficiency:Ntsuam xyuas tag nrho cov nqi-zoo thiab efficiency ntawm cov txheej txheem tuag casting.Xav txog yam xws li cov nqi ntawm cov khoom siv, cov nqi siv, lub sij hawm ntau lawm, kev siv hluav taws xob, thiab kev ua haujlwm.Sib piv qhov zoo thiab kev txwv ntawm cov txheej txheem sib txawv los txiav txim siab qhov kev xaiv zoo tshaj plaws rau cov kev xav tau ntau lawm.

Kev paub thiab kev paub:Coj mus rau hauv tus account qhov kev txawj ntse thiab kev paub muaj nyob rau hauv koj lub koom haum lossis los ntawm cov neeg muab khoom tuag casting.Qee cov txheej txheem yuav xav tau kev paub tshwj xeeb, kev txawj ntse, thiab kev teeb tsa khoom siv.Ntsuam xyuas cov peev txheej thiab kev paub dhau los ntawm koj pab neeg lossis cov neeg koom tes uas muaj peev xwm los xyuas kom muaj kev ua tiav ntawm cov txheej txheem tuag casting.

Los ntawm kev ua tib zoo xav txog cov xwm txheej no thiab sab laj nrog cov kws tshaj lij hauv thaj chaw, koj tuaj yeem txiav txim siab paub thiab xaiv cov txheej txheem tuag casting tsim nyog tshaj plaws rau koj qhov xwm txheej tshwj xeeb.

Txais tos rau Xiamen Ruicheng xws li tus neeg muag khoom muaj zog los sab laj, koj yuav tau txais cov lus qhia tshaj lij!

Post lub sij hawm: Feb-05-2024