Niaj hnub no cov khoom yas 'daim ntawv thov tag nrho peb lub neej, txawm nyob hauv tsev lossis kev lag luam.Tab sis koj puas paub yuav ua li cas ua ib tugyas ntu?Mus nyeem ntawv, kab lus no yuav qhia rau koj.

Dab tsi yog txhaj pwm

Kev txhaj tshuaj molding feem ntau txhais tau tias yog ib qho thermoplastic polymer yog rhuab saum nws cov ntsiab lus melting, uas ua rau kev hloov pauv ntawm cov khoom polymer mus rau cov kua dej molten nrog cov viscosity tsawg.Qhov no yaj yog mechanically yuam, uas yog, txhaj, rau hauv pwm nyob rau hauv cov duab ntawm yam khoom kawg xav tau.Rau kev lag luam ntau lawm, kev txhaj tshuaj molding yog ib qho tseem ceeb tshaj plaws rau kev tsim cov khoom los ntawm cov thermoplastics.Cov neeg ua haujlwm feem ntau muab cov khoom siv yas qhuav qhuav (xws li: ABDS, PP, TPU, PA66) rau hauv lub thoob ntawm lub tshuab txhaj tshuaj molding.Tom qab ntawd raws li cov khoom siv sib txawv, qhov sib txawv kub thiab kev txhaj tshuaj nrawm yog tsim.Tom qab ntawd teem caij sib txawv thiab txhaj tshuaj nrawm raws li cov khoom siv sib txawv.Tom qab qhov kawg txias los tsim cov khoom, nws yog ejected los ntawm ejector tus pin.

Vim li cas thiaj xav tau kev cai txhaj tshuaj pwm

1.Cov khoom ntiag tug thiab kev ruaj ntseg

Thaum lub sij hawm cov txheej txheem tso tawm cov khoom, nws feem ntau tshwm sim tias cov khoom uas tau tsim tau ntev tau raug pirated ua ntej lawv tso tawm.Qhov no feem ntau yog vim qhov tseeb tias cov neeg siv khoom siv ntau hom pwm npaj tau los ua ke rau lawv ua ke thaum tsim thiab txhaj tshuaj molding txheej txheem, thiab tsis muaj lawv tus kheej cov pwm.Thaum koj kho cov pwm tshwj xeeb rau koj cov khoom, qhov teeb meem no yuav tsis tshwm sim ntxiv lawm, vim tias peb yuav khaws cov pwm ntawm lub hauv paus ntsiab lus uas tsuas yog koj tuaj yeem siv tau, thiab ua haujlwm tsis tu ncua ntawm lawv rau koj cov txiaj ntsig.Siv nws txhua lub sijhawm tom qab.

2. Kev nyuaj siab

Thaum koj xaiv los kho cov txheej txheem pwm, koj cov khoom yuav tsis raug txwv los ntawm cov qauv thiab pwm.Vim muaj kev ywj pheej siab ntawm kev hloov kho, koj tuaj yeem tsim cov khoom tsim cov khoom sib txawv raws li koj xav tau es tsis txhob sib txuas ua ke los ntawm ntau yam pwm.Qhov no yuav zoo heev txhim kho kev ncaj ncees thiab kev ncaj ncees ntawm cov khoom.Nrog rau tam sim no ntau yam kev siv ntawm kev txhaj tshuaj pwm thiab 3D kos duab, cov khoom koj tsim muaj peev xwm los ntawm tsev neeg mus rau cov khoom lag luam.

3. Tus nqi qis dua

Los ntawm kev pom ntau lawm, kev kho cov pwm tuaj yeem xav tau tus nqi siab dua li kev siv pwm npaj.Txawm li cas los xij, los ntawm kev pom ntau lawm, kev txhaj tshuaj molding yog txheej txheem ntau lawm thiab siv sijhawm ntev ntawm cov pwm npaj ua rau kev sib txuas ntau lawm.Cov nqi tom ntej yog siab heev, yog li thaum koj xaiv cov pwm customized, koj yuav tsis tas them dab tsi rau pwm.

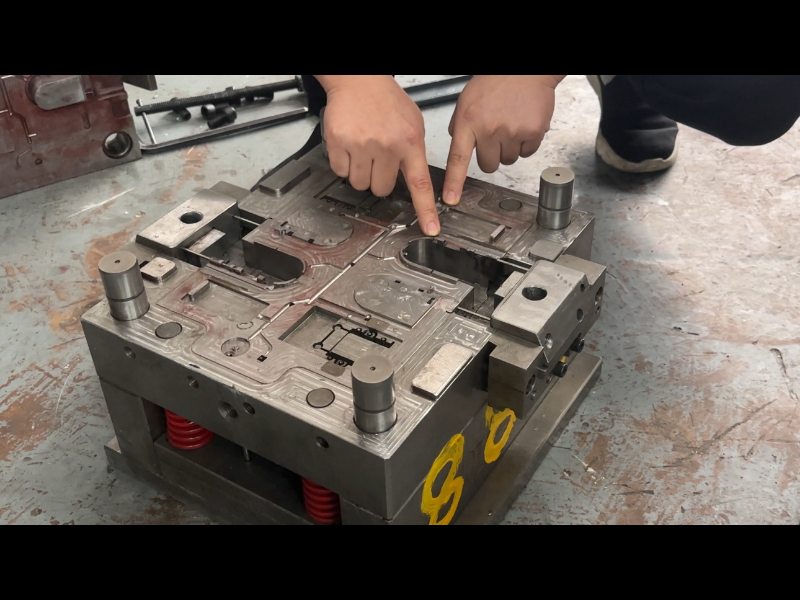

Yuav ua li cas txhaj tshuaj pwm

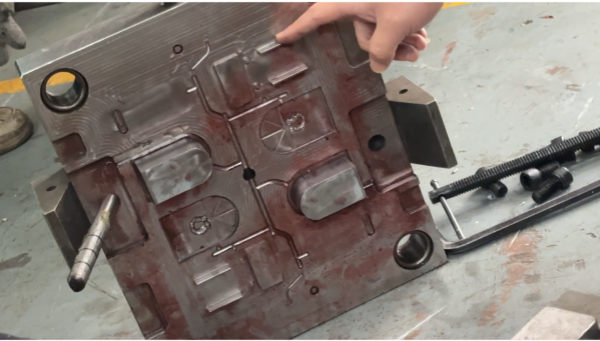

Tsim Mould hauv CAD

Kev tsim cov pwm yog ib qho tseem ceeb tshaj plaws hauv cov txheej txheem.Qhov no yog kauj ruam uas koj yuav tsum txiav txim siab seb qhov yuav zoo li cas, nws yuav ua li cas thiab nws yuav muaj dab tsi.Kev txhaj tshuaj molding yog txheej txheem nyuaj, thiab pwm yog qhov tseem ceeb ntawm qhov ntawd.Cov pwm yuav tsum muaj peev xwm tiv taus qhov kub siab thiab kub ntawm cov txheej txheem txhaj tshuaj, nrog rau kev siv dua.Tias yog vim li cas nws yog ib qho tseem ceeb kom tau txais kev tsim cov pwm yog thawj zaug.CAD software tuaj yeem pab koj tsim 3D qauv zoo meej ntawm koj qhov uas koj tuaj yeem siv los tsim pwm.

3D Sau Mould

Cov kauj ruam kawg yog luam cov pwm siv lub tshuab luam ntawv 3D.Qhov no yuav tsim qhov kawg, qhov loj ntawm pwm.Yog tias koj tsis paub yuav ua li cas mus txog qhov no, muaj ntau cov kev qhia hauv online los pab koj.Koj tseem tuaj yeem nrhiav cov kev pabcuam 3D luam ntawv uas yuav ua haujlwm rau koj.Kev luam ntawv pwm yog ib kauj ruam tseem ceeb, vim nws yuav ua kom cov khoom tiav yog qhov zoo tshaj plaws.

Yog tias koj xav paub ntau ntxiv txog kev tsim pwm, koj tuaj yeem nyeemPwm Tsim thiab tsim khoom rau cov khoom siv yas

Cov teeb meem tshwm sim hauv kev ua pwm

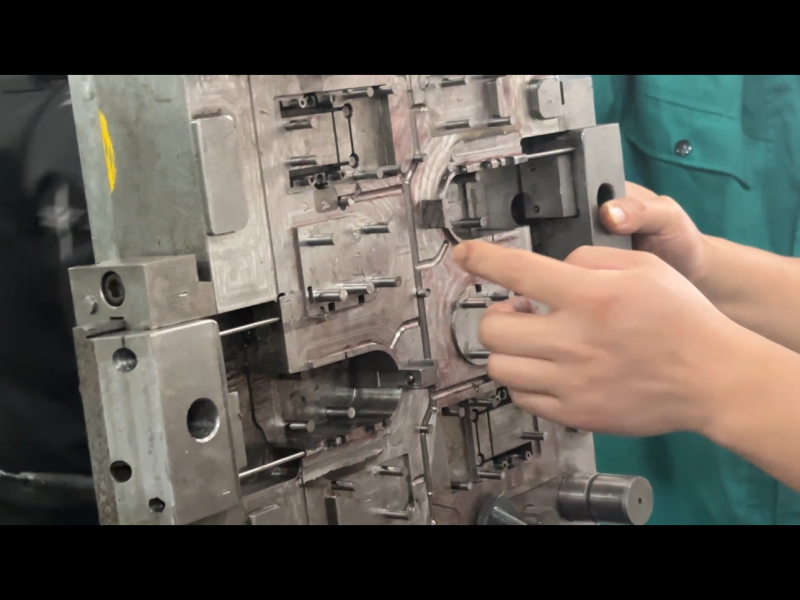

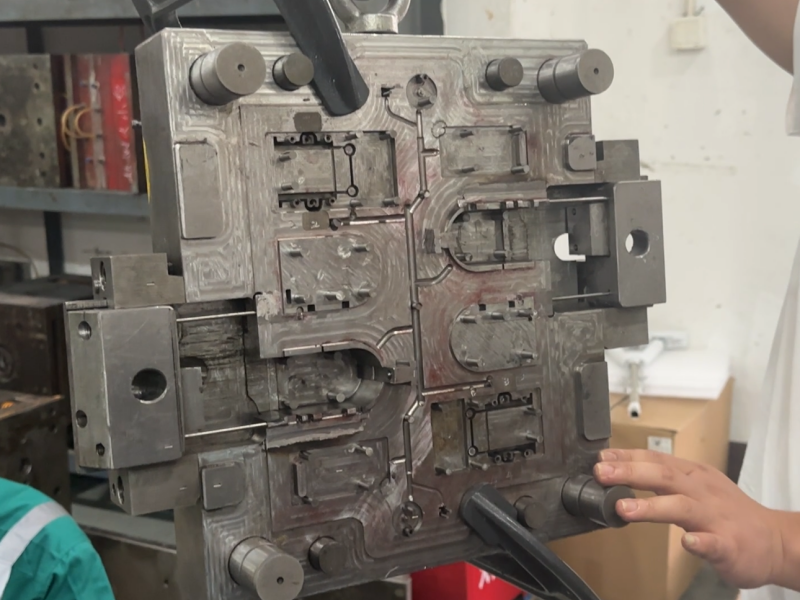

1. swb

Thaum lub slider yog ua ke los ntawm splicing, nws tsis tuaj yeem haum cov pwm.Thaum cov pwm qhib thiab kaw, nws yog ib qho yooj yim ua rau lub inclined sab saum toj tawg.

2. dej channel

Tsis muaj dej ntws channel tau npaj thaum tsim cov pwm, uas ua rau muaj teeb meem nrog cov khoom txias.Tsis tas li ntawd, tom qab siv cov pwm mus ntev, qhov kub ntawm cov pwm yuav nce siab thiab siab dua, nws thiaj li ua rau deformation ntawm cov khoom los yog sib txawv ntawm qhov chaw ntawm lub qhov.

3. Pwm hnav

Thaum lub sij hawm tsim txheej txheem ntawm pwm, vim tias tsis muaj qhov txuas ntxiv los tso cai rau cov roj lubricate cov pwm, kev sib txhuam coefficient ntawm cov hlau thaiv thaum lub sij hawm sib tsoo loj heev, ua rau cov pwm puas.

4.Product slot allocation yog tsis tsim nyog

Txij li thaum txhaj tshuaj molding yuav tsum tau txhaj tshuaj kub kub molten kua clinker rau hauv qhov zawj ntawm cov pwm rau qhov kawg txias ntawm cov khoom, cov pwm kab noj hniav ntawm cov khoom loj yuav tsum tau nyob ze rau cov kua nplaum inlet kom tiv thaiv qhov kub ntawm qhov txias vim qhov kev ncua deb thiab qhov tsis muaj peev xwm txhaj tshuaj rau hauv pwm.Tab sis cov pwm rau cov khoom me me yuav tsum muaj cov yas tsawg, yog li cov grooves feem ntau yog tsim los ntawm ntug ntawm cov pwm.

5.Cov hlau tseem nyob hauv cov pwm qub

Cov hlau tseem nyob hauv cov pwm qub tsis hloov los ntawm kev ntxig.Yog tias kev puas tsuaj tshwm sim tom qab, tag nrho cov seem ntawm lub cev qub yuav tsum tau txiav cov hlau thiab rov qab tso rau hauv.

Yog tias koj xav paub ntau yam ntaub ntawv ntsig txog kev txhaj tshuaj molding txheej txheem lossis pwm ua, thov koj xav tiv taujtiv tauj peb pab neeg tshaj lij.

Lub sij hawm xa tuaj: Plaub Hlis-18-2024