Pwm Tsim thiab tsim khoom rau cov khoom siv yas: Kev ua kom zoo tshaj plaws thiab cov kev daws teeb meem tshiab

Hauv kev tsim kev lag luam, kev tsim cov khoom siv yas thiab kev tsim cov pwm yog cov theem tseem ceeb.Kab lus no yuav tham txog cov qauv tsim rau cov khoom siv yas, pwm tsim thiab kev tsim khoom, thiab qhia qee qhov kev ua kom zoo rau kev tsim, kev txiav txim siab rau pwm tsim, thiab cov kev daws teeb meem tshiab.

Tsim Cov Ntsiab Cai rau Cov Khoom Siv Yas:

Kev xaiv cov khoom siv: Xaiv cov khoom siv yas uas tsim nyog, xws li polypropylene, polyurethane, raws li cov kev xav tau ntawm daim ntawv thov, kev xav tau ntawm cov khoom siv, thiab cov kav ntev.

Tus Qauv Tsim: Xav txog kev ua haujlwm thiab kev sib dhos ntawm cov khoom siv, thiab tsim cov qauv tsim nyog, qhov ntev, thiab txoj kev sib txuas.

Phab ntsa Thickness Control: Txo cov phab ntsa tuab thaum ua kom cov khoom tiv thaiv lub zog thiab nruj kom txo tau cov nqi thiab cov khoom siv.

Khoov thiab Twist Design: Zam cov kaum ntse ntse thiab cov txheej txheem ntau dhau los txhawm rau txhim kho pwm tsim tau thiab muaj zog tiv thaiv.

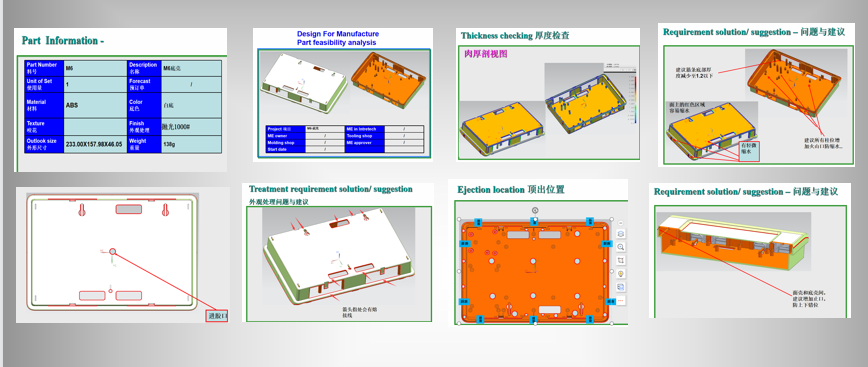

Kev xav txog kev txhaj tshuaj molding: Xav txog cov yam ntxwv ntawm kev txhaj tshuaj molding thaum lub sijhawm tsim, xws li qhov chaw ntawm lub qhov rooj, qhov cua txias, thiab qhov cua tshuab, txhawm rau txhim kho molding zoo thiab ntau lawm efficiency.

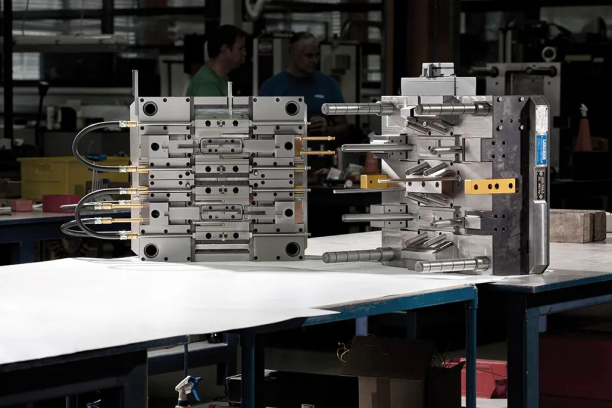

Kev txiav txim siab rau Mould Design thiab Manufacturing:

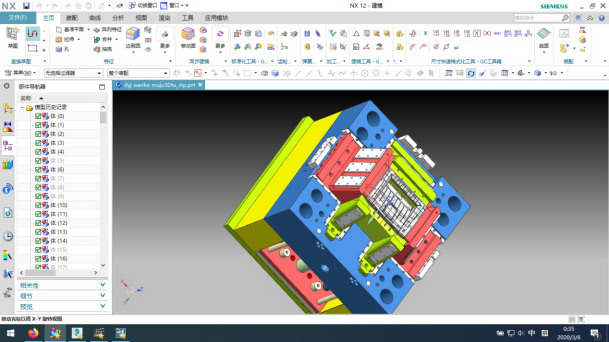

Pwm Cov Khoom Xaiv: Xaiv cov khoom pwm tsim nyog, xws li cov cuab yeej hlau, raws li cov khoom yuav tsum tau ua thiab cov khoom tsim tawm.

Mould Structure Design: Xav txog cov duab, qhov loj me, thiab cov txheej txheem molding ntawm cov khoom siv los tsim cov pwm tsim, nrog rau cov kab noj hniav, core, thiab ejector pins.

Cooling System Design: Tsim kom muaj lub tshuab ua kom txias kom zoo dua qhov txias txias thaum lub sij hawm txhaj tshuaj molding txheej txheem thiab txo lub sij hawm molding.

Venting System Design: Tsim ib qho kev tso cua kom tsim nyog los tiv thaiv kev tsim cov npuas thiab qhov tsis xws luag, kom ntseeg tau tias kev tso tawm ntawm cov pa roj hauv cov pwm.

Kev Kho Hniav thiab Polishing: Siv cov kev kho deg tsim nyog thiab polishing raws li cov kev xav tau los ua kom tiav qhov zoo ntawm qhov chaw.

Optimization Techniques for Design:

Ua kom pom tseeb ntawm cov phab ntsa tuab, tsis txhob ua kom nyias nyias los yog tuab qhov chaw los txhim kho cov khoom siv zog thiab molding zoo.

Optimize tivthaiv geometry kom txo cov npoo ntse, cov ces kaum, thiab cov kev hloov pauv hloov pauv, txo qhov nyuaj thiab tus nqi ntawm kev tsim pwm.

Xav txog qhov yuav tsum tau ua los ua ke thiab kam rau ua kom haum thiab kev sib txuas ntawm cov khoom.

Siv cov qauv tsim lub teeb hnyav los txo cov khoom hnyav thiab siv cov khoom siv, txuag cov nqi thiab cov peev txheej.

Kev daws teeb meem tshiab:

Siv cov thev naus laus zis tsim khoom ntxiv, xws li 3D luam ntawv, kom nrawm nrawm thiab qauv tsim kom siv tau cov qauv tsim thiab cov duab.

Siv cov khoom siv ruaj khov thiab cov txheej txheem tsim khoom los txhawb kev phooj ywg ib puag ncig thiab kev txhim kho kom ruaj khov.3d cov khoom luam tawm rau kev tsim qauv thiab qauv kuj yog ib qho ntawm peb cov kev pabcuam zoo tshaj plaws.

Los ntawm kev ua raws li cov qauv tsim, ua tib zoo saib cov pwm tsim thiab tsim cov ntsiab lus, thiab siv cov txheej txheem kev ua kom zoo dua qub thiab cov kev daws teeb meem tshiab, qhov zoo, kev ua tau zoo, thiab kev ruaj khov ntawm cov khoom siv yas tsim thiab pwm tsim tuaj yeem txhim kho.

Ntxiv nrog rau kev muab cov khoom tsim cov kev pabcuam, peb lub tuam txhab muaj ib pab neeg ua haujlwm ntawm cov kws tsim pwm tsim.Txawm hais tias nws tab tom tsim cov khoom yas tshiab los ntawm khawb lossis txhim kho ib qho uas twb muaj lawm, peb cov neeg tsim qauv muaj kev paub dhau los thiab kev txawj ntse los xa cov kev daws teeb meem zoo.

Peb pab neeg tsim khoom yuav koom tes nrog koj kom nkag siab txog koj cov kev xav tau thiab cov kev xav tau, thiab muab cov kev daws teeb meem tsim tshiab raws li koj qhov tshwj xeeb.Txawm hais tias nws yog cov khoom siv yas xaiv, cov qauv tsim qauv, phab ntsa thickness optimization, los yog pwm tsim, peb cov neeg tsim qauv yuav muab cov kws tshaj lij tswv yim los xyuas kom meej cov lus pom zoo tsim.

Ntxiv mus, kev txaus siab ntawm cov neeg siv khoom yog qhov tseem ceeb tshaj plaws rau peb, thiab peb txaus siab muab cov pwm dawb / cuab yeej tsim / DFM cov kev pabcuam rau koj kom ntseeg tau tias koj txaus siab rau qhov kawg tsim kev daws teeb meem.Peb lub hom phiaj los tsim kom muaj kev koom tes ntev nrog koj thiab muab kev txhawb nqa tsis tu ncua rau koj cov haujlwm.Yog tias koj muaj kev xav tau ntawm cov khoom tsim lossis pwm tsim, thov hu rau peb pab neeg txhua lub sijhawm.Peb tos ntsoov yuav ua haujlwm nrog koj thiab muab kev pabcuam zoo rau koj.

Post lub sij hawm: Dec-12-2023