Txhaj Molding yog dab tsi?

Kev txhaj tshuaj molding yog txheej txheem tsim khoom uas yuav tsum tau txhaj cov yas yaj rau hauv pwm thiab tso cai rau nws kom txias thiab khov kho los tsim cov khoom kawg.Nws yog siv dav hauv kev tsim khoom ntawm ntau yam khoom yas, xws li cov khoom me me mus rau cov thawv loj thiab ntim khoom.

Ntawm no yog cov txheej txheem txhaj tshuaj molding:

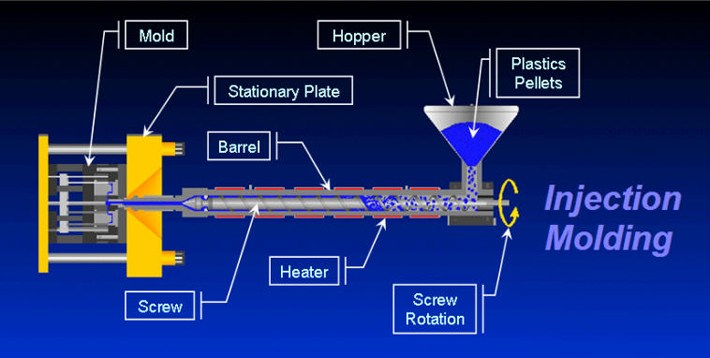

① Pwm Tsim: Cov pwm siv rau hauv cov txheej txheem txhaj tshuaj molding feem ntau muaj ob ntu: kev txhaj tshuaj pwm thiab cov pwm clamping.Cov pwm txhaj tshuaj muaj cov txheej txheem txhaj tshuaj rau txhaj cov yas yaj rau hauv pwm.Lub clamping pwm yog siv los tuav cov pwm thiab kev txhaj tshuaj thaum lub sijhawm txhaj tshuaj.

②Plastic Melting: Thaum lub sij hawm txhaj tshuaj molding txheej txheem, cov khoom yas pellets los yog granules yog rhuab thiab yaj los ua molten yas uas yuav txhaj rau hauv pwm.Cov cua kub cua sov los yog cov cua sov feem ntau yog siv los ua kom sov cov yas saum nws cov ntsiab lus melting, thiab cov yas yaj tau raug thawb rau hauv lub tog raj kheej los ntawm cov ntsia hlau.

③ Txheej Txheej: Thaum cov yas yaj yaj mus txog qhov xav tau qhov kub thiab viscosity, cov txheej txheem txhaj tshuaj pib.Cov ntsia hlau nce qib hauv kev txhaj tshuaj lub tog raj kheej, tshem tawm cov yas yaj los ntawm lub hopper thiab txhaj rau hauv pwm kab noj hniav los ntawm lub nozzle.

④Filling thiab txias: Cov yas molten puv lub pwm kab noj hniav, sau cov duab thiab cov voids ntawm pwm.Thaum sau tiav lawm, cov yas pib txias thiab solidify nyob rau hauv pwm.Lub sijhawm txias yog nyob ntawm yam xws li hom yas, qhov loj me, thiab pwm tswj qhov kub thiab txias.

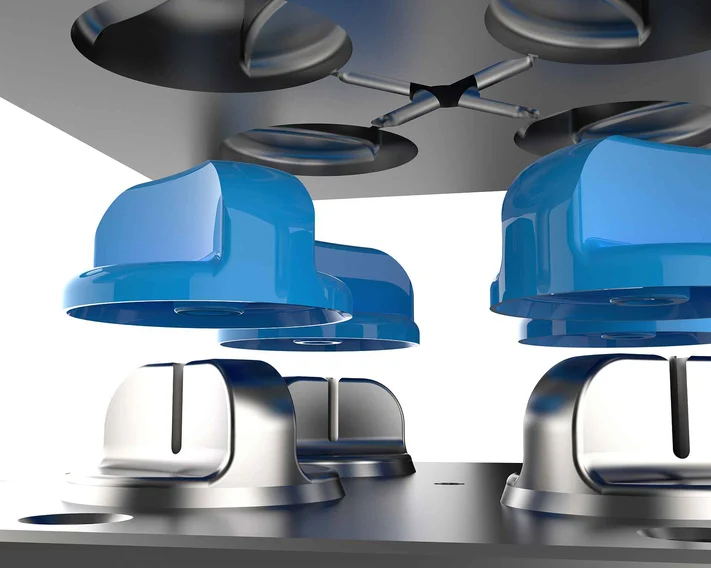

⑤ Pwm qhib thiab ejection: Tom qab cov yas tau txias thiab solidified, pwm qhib, thiab cov khoom tiav lawm ejected.Cov txheej txheem qhib pwm feem ntau yog tswj los ntawm cov springs, hydraulic systems, lossis mechanical systems ntawm pwm.Thaum cov khoom tiav lawm raug tshem tawm ntawm cov pwm, pwm yog npaj rau lub voj voog txhaj tshuaj tom ntej.

⑥Post-Processing: Tom qab txhaj tshuaj molding tiav lawm, tej zaum yuav tsum tau ib co tom qab ua cov kauj ruam, xws li trimming, tshem flash, painting, los yog assembling ntxiv Cheebtsam kom tiav cov khoom yas zaum kawg.

Vim li cas txhaj Moulding tseem ceeb?

Kev txhaj tshuaj molding muaj ntau qhov zoo uas ua rau nws ua cov txheej txheem tseem ceeb hauv kev tsim khoom.Ua ntej, kev txhaj tshuaj molding ua rau kev tsim cov khoom yas zoo heev, ua kom cov khoom zoo thiab sib xws.Qhov thib ob, nws yog txoj kev tsim khoom zoo, muaj peev xwm ua tau ntau yam ntawm cov khoom yas hauv lub sijhawm luv luv.Tsis tas li ntawd, kev txhaj tshuaj molding tso cai rau kev tsim cov duab thiab cov qauv tsim kom tau raws li kev lag luam sib txawv.

Kev txhaj tshuaj molding pom dav siv hauv kev lag luam xws li tsheb, hluav taws xob, khoom siv kho mob, ntim khoom, thiab lwm yam.Los ntawm cov khoom siv hauv tsheb mus rau cov xov tooj ntawm tes, los ntawm lub raj mis yas mus rau cov thawv ntim khoom noj, kev txhaj tshuaj molding tshuab yog ubiquitous.

Dab tsi ntawm cov neeg siv khoom xav paub txog cov txheej txheem ntawm kev txhaj tshuaj molding?

Cov neeg tsim khoom tsim:Cov neeg tsim khoom lag luam yuav tsum nkag siab txog cov txheej txheem ntawm kev txhaj tshuaj molding los txiav txim siab nws cov kev xav tau thiab kev txwv thaum lub sijhawm tsim qauv.Lawv yuav tsum paub txog yam xws li pwm tsim, xaiv cov khoom siv, thiab kev tswj cov phab ntsa tuab kom ntseeg tau tias cov khoom tsim tuaj yeem ua tau zoo los ntawm kev txhaj tshuaj molding thiab ua tau raws li cov qauv kev xav tau.

Pab neeg tsim khoom thiab cov khoom tsim tawm:Cov neeg tsim khoom thiab pab pawg tsim khoom yuav tsum nkag siab txog cov txheej txheem ntawm kev txhaj tshuaj molding los coj lawv cov kev txiav txim siab thaum lub sijhawm tsim khoom.Lawv yuav tsum paub txog ntau yam kev txhaj tshuaj molding kev xaiv, xws li xaiv cov khoom, pwm tsim, thiab ntau lawm batch loj, txhawm rau txhim kho tus nqi tsim khoom thiab zoo ntawm cov khoom.

Cov neeg ua haujlwm muag khoom:Cov thawj coj yuav tsum nkag siab txog cov txheej txheem ntawm kev txhaj tshuaj molding los soj ntsuam thiab xaiv cov neeg muab khoom zoo.Kev nkag siab txog cov txheej txheem ntawm kev txhaj tshuaj molding pab lawv ntsuam xyuas lub peev xwm thiab kev txawj ntse ntawm cov neeg muag khoom, ua rau lawv txiav txim siab txog kev yuav khoom.

Manufacturing kev lag luam cov neeg muas zaub:Cov neeg siv khoom hauv kev tsim khoom lag luam yuav tsum nkag siab txog cov txheej txheem ntawm kev txhaj tshuaj molding kom sib koom tes zoo nrog cov tuam ntxhab.Los ntawm kev nkag siab txog cov txheej txheem, lawv tuaj yeem tsim cov lus nug, muab cov lus qhia, thiab koom nrog hauv kev tsim khoom thiab tsim cov txheej txheem los xyuas kom meej tias cov khoom ua tau raws li lawv cov kev xav tau thiab kev cia siab.

Tsis muaj teeb meem dab tsi ntawm cov neeg siv khoom koj yog, Yog tias koj tab tom nrhiav rau lub npe nrov yas txhaj tshuaj pwm chaw tsim tshuaj paus, thov hu rau peb kom paub cov lus qhia ntxaws.Trust peb kom ua tau raws li koj xav tau thiab tshaj qhov koj xav tau!

Post lub sij hawm: Dec-07-2023