Txhaj tshuaj molding nto tiav raws li SPI thiab VDI kev faib cov tshuab - Gloss, semi-gloss, matte thiab textured nto tiav.

Cov ntsiab lus tau hais hauv tsab xov xwm no

Kev txhaj tshuaj molding nto tiav yog dab tsi?

INjection molding nto tiavNws yog ib qho tseem ceeb rau kev tsim ib feem ua tiav thiab siv rau kev zoo nkauj thiab kev ua haujlwm ntawm cov yas txhaj tshuaj molding qhov chaw rau engineering khoom.Qhov saum npoo tiav txhim kho qhov zoo thiab qhov zoo ntawm cov khoom raws li qhov pom tau tias tus nqi thiab qhov zoo ntawm cov khoom nce ntxiv nrog rau qhov tsim nyog tiav.

Plastic Case (Source: XR USA Client)

Vim li cas thiaj siv cov khoom tiav hauv kev txhaj tshuaj molding?

Txhawm rau nce ib feem aesthetics

Cov neeg tsim khoom siv tuaj yeem siv textures rau ntau hom kev zoo nkauj.Ib tug du los yog matte nto zoo nkauj txhim kho nws cov tsos thiab muab nws ib tug polished nam.Nws kuj tseem suav nrog qhov tsis raug tsim los ntawm kev txhaj tshuaj molding, xws li cov cuab yeej siv tshuab, cov cim dab dej, cov kab txuas, cov kab ntws, thiab cov duab ntxoov ntxoo.Qhov chaw nrog zoo heev nto zoo thov ntau rau cov neeg muas zaub los ntawm ib tug lag luam standpoint.

Txhawm rau txhim kho kev ua haujlwm ib feem

Ib cag ntawm cov kev xav zoo nkauj uas nkag mus rau hauv kev xaiv qhov kev txhaj tshuaj molding nto tiav, kuj tseem muaj cov kev xav tau tseem ceeb.

Kev tsim qauv yuav xav tau kev tuav ruaj khov rau kev ua haujlwm zoo.Textured yas finishes txhim kho tuav zoo.Yog li kev txhaj tshuaj molding nto kev kho mob feem ntau siv los ntawm cov khoom siv slip-resistant.Ib qho pwm zoo nkauj kuj tuaj yeem pab kom khiav tawm ntawm cov pa phem.

Ib qho SPI nto tiav yuav ua rau cov xim tev tawm.Txawm li cas los xij, lub ntsej muag ntxhib tuaj yeem ua kom ntseeg tau tias cov xim zoo dua rau cov khoom molded.Kev kho mob SPI textured nto kuj ua rau lub zog thiab kev nyab xeeb.

Kev ntxhib los mos muaj ntau qhov zoo, suav nrog:

- Yas flow creases-Cov creases no yuav raug tshem tawm los ntawm kev ntxiv textured thickness thaum ua kom lub zog thiab cov khoom tsis zoo.

- Txhim kho tuav- Ntxiv kev ntxhib los mos rau cov khoom ua kom tuav tau yooj yim dua, ua kom muaj txiaj ntsig thiab kev nyab xeeb hauv cov ntawv thov tshwj xeeb.

- Xim adhesion-Cov xim ua kom ruaj khov rau cov khoom siv textured thaum lub sij hawm molding tom ntej.

- Ua undercuts-Yog tias koj muaj ib feem uas yuav tsis tas mus li mus rau ib nrab ntawm cov pwm, kev ntxhib los mos ntawm txhua qhov chaw tuaj yeem muab cov pu tsim nyog.ll.

Txhaj pwm cov cuab yeej nto tiav specifications

Txoj hauv kev tshaj plaws los qhia qhov chaw txhaj tshuaj molding yog sivPIA (los yog SPI), VDIthiabPwm-techqauv.Cov cuab yeej txhaj tshuaj pwm, cov tuam txhab tsim khoom thiab cov kws tsim qauv tsim thoob ntiaj teb lees paub peb cov qauv no thiab cov qauv PIA yog qhov muaj ntau dua thiab dav hu ua "SPI qib".

Gloss tiav - Qib A - Pob zeb diamond tiav

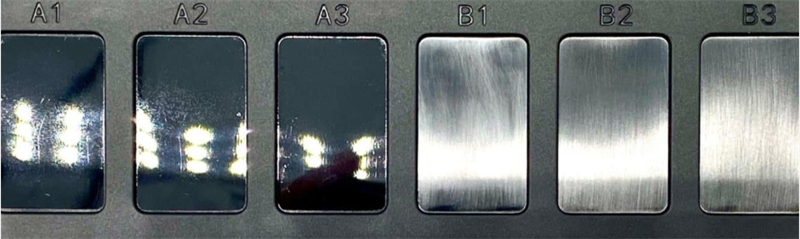

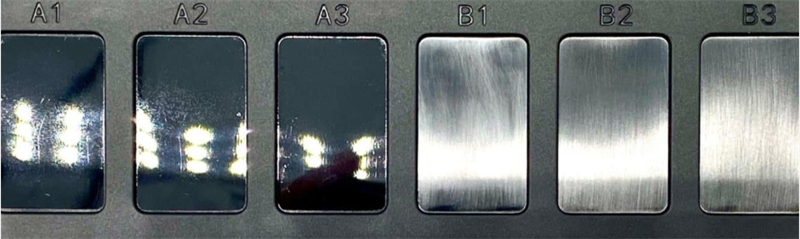

(SPI-AB Txhaj-moulding nto tiav)

Cov qib "A" tiav no yog du, glossy, thiab kim tshaj plaws.Cov qib no yuav xav tau cov cuab yeej hardened steel pwm, uas yog buffed siv ntau qib ntawm pob zeb diamond buff.Vim hais tias ntawm cov nplua-grain buffing muab tshuaj txhuam thiab random directional rotary polishing txoj kev, nws yuav tsis muaj ib tug meej kev ntxhib los mos thiab tawg lub teeb rays, muab ib tug glossy tag.Cov no tseem hu ua "Pob zeb tiav" lossis "buff tiav" lossis "A tiav"

| Ua kom tiav | SPI Txuj | Txoj kev ua tiav | Nto Roughness (Ra Tus Nqi) |

| High Glossy tiav | A1 | 6000 Grit pob zeb diamond buff | 0.012-0.025 Nws |

| High Glossy tiav | A2 | 3000 Grit pob zeb diamond buff | 0.025-0.05 Nws |

| Ib txwm Glossy tiav | A3 | 1200 Pob zeb diamond buff | 0.05-1.00 Nws |

SPI gloss qib yog tsim rau cov khoom nrog ib tug du nto tiav rau kom hniav zoo nkauj thiab haumxeeb vim li cas.Piv txwv li, A2 yog cov pob zeb diamond feem ntau siv hauv kev lag luam, ua rau pom qhov pom kev zoo siab nrog kev tso tawm zoo.Tsis tas li ntawd, qib "A" nto tiav yog siv rau ntawm qhov chaw kho qhov muag xws li lo ntsiab muag, iav, thiab visors.

Semi-gloss tiav - Qib B

(Fig 2.SPI-AB Txhaj-moulding nto tiav)

Cov semi-gloss tiav no yog qhov zoo rau kev tshem tawm machining, molding, thiab cov cuab yeej kos nrog tus nqi tsim nyog.Cov kev ua tiav saum npoo no yog tsim los siv cov qib sib txawv ntawm cov ntawv xuab zeb siv nrog cov lus tsa suab, muab cov qauv kab raws li qhia hauv daim duab 2.

| Ua kom tiav | SPI Txuj | Txoj kev ua tiav | Nto Roughness (Ra Tus Nqi) |

| Fine Semi Glossy Finish | B1 | 600 Grit Ntawv | 0.05 rau 0.1 |

| Nruab nrab Semi Glossy Finish | B2 | 400 Grit Ntawv | 0.1 rau 0.15 |

| Ib txwm emi Glossy Finish | B3 | 320 Grit Ntawv | 0.28 rau 32 |

SPI (B 1-3) semi-gloss nto tiav yuav muab qhov pom kev zoo thiab tshem tawm cov cuab yeej pwm.Cov no feem ntau siv nyob rau hauv qhov chaw uas tsis yog cov hniav zoo nkauj lossis pom qhov tseem ceeb ntawm cov khoom.

Matte tiav - Qib C

Cov no yog cov feem ntau pheej yig thiab nrov nto finishes, polished siv zoo pob zeb hmoov.Qee lub sij hawm hu ua pob zeb tiav, nws muab kev tso tawm zoo thiab pab zais cov cim machining.Qib C kuj yog thawj kauj ruam ntawm qib A thiab B nto tiav.

| Ua kom tiav | SPI Txuj | Txoj kev ua tiav | Nto Roughness (Ra Tus Nqi) |

| Medium Matte tiav | C1 | 600 Grit Pob Zeb | 0.35 rau 0.4 |

| Medium Matte tiav | C2 | 400 Grit Ntawv | 0.45-0.55 Nws |

| Li qub Matte Finish | C3 | 320 Grit Ntawv | 0.63-0.70 Nws |

Textured tiav - Qib D

Nws muab qhov tsim nyog qhov pom kev zoo nkauj thiab siv dav hauv cov khoom lag luam thiab cov neeg siv khoom.Cov no tsim nyog rau qhov chaw uas tsis muaj kev xav pom tshwj xeeb.

| Ua kom tiav | SPI Txuj | Txoj kev ua tiav | Nto Roughness (Ra Tus Nqi) |

| Satin Texture tiav | D1 | 600 pob zeb ua ntej qhuav moj tej tawg iav hlaws #11 | 0.8 rau 1.0 |

| Qhuav Texture tiav | D2 | 400 pob zeb ua ntej qhuav moj tej tawg iav #240 oxide | 1.0 rau 2.8 |

| Rough Texture tiav | D3 | 320 pob zeb ua ntej qhuav moj tej tawg #24 oxide | 3.2-18.0 Nws |

Tsis muaj leej twg tau hais tias tsim thiab tsim cov khoom pwm yog qhov yooj yim.Peb lub hom phiaj yog kom koj hla nws sai thiab nrog cov khoom zoo.

VDI Txhaj molding nto tiav

VDI 3400 Surface Finish (feem ntau hu ua VDI nto tiav) yog hais txog cov pwm kev ntxhib los mos tsim los ntawm Verein Deutscher Ingenieure (VDI), Lub Koom Haum ntawm German Engineers.VDI 3400 nto tiav yog ua tiav los ntawm Hluav Taws Xob Hluav Taws Xob Machining (EDM) thaum pwm machining.Nws kuj tseem tuaj yeem ua tau los ntawm cov txheej txheem kev ntxhib los mos (xws li hauv SPI).Txawm hais tias cov qauv tsim los ntawm zej zog ntawm German Engineers nws yog feem ntau siv los ntawm cov neeg tsim khoom thoob plaws, suav nrog North America, Europe, thiab Asia.

VDI qhov tseem ceeb yog nyob ntawm qhov chaw roughness.Los ntawm daim duab, peb pom cov textures sib txawv ntawm qhov chaw tiav nrog qhov sib txawv ntawm qhov roughness ntawm qhov chaw.

| VDI Tus nqi | Kev piav qhia | Daim ntawv thov | Nto roughness (Ra µm) |

| 12 | 600 Pob zeb | Tsawg polish qhov chaw | 0.40 Nws |

| 15 | 400 Pob zeb | Tsawg polish qhov chaw | 0.56 ib |

| 18 | Dry Blast Glass Bead | Satin tiav | 0.80 ib |

| 21 | Qhuav Blast # 240 Oxide | Nplaum tiav | 1.12 |

| 24 | Qhuav Blast # 240 Oxide | Nplaum tiav | 1.60 ib |

| 27 | Qhuav Blast # 240 Oxide | Nplaum tiav | 2.24 |

| 30 | Qhuav Blast #24 Oxide | Nplaum tiav | 3.15 |

| 33 | Qhuav Blast #24 Oxide | Nplaum tiav | 4.50 Nws |

| 36 | Qhuav Blast #24 Oxide | Nplaum tiav | 6.30 Nws |

| 39 | Qhuav Blast #24 Oxide | Nplaum tiav | 9.00 Nws |

| 42 | Qhuav Blast #24 Oxide | Nplaum tiav | 12.50 Nws |

| 45 | Qhuav Blast #24 Oxide | Nplaum tiav | 18.00 Nws |

Xaus

Tawm ntawm ob pawg ntawm kev txhaj tshuaj molding nto tiav, SPI qib A thiab B raug suav hais tias yog qhov smoothest nrog qhov tsis tshua muaj roughness thiab kim dua.Whereas, los ntawm qhov chaw roughness ntawm qhov pom, VDI 12, qhov zoo tshaj plaws VDI, sib npaug SPI C qib.

Tsis muaj leej twg tau hais tias tsim thiab tsim cov khoom pwm yog qhov yooj yim.Peb lub hom phiaj yog kom koj hla nws sai thiab nrog cov khoom zoo.

Yuav ua li cas xaiv ib tug haum txhaj molding nto tiav?

Xaiv qhov kev txhaj tshuaj molding nto tiav los ntawm kev txiav txim siab txog kev ua haujlwm, cov khoom siv, thiab kev xav pom.Feem ntau ntawm cov khoom siv yas txhaj tshuaj molded tuaj yeem muaj ntau yam kev ua tiav.

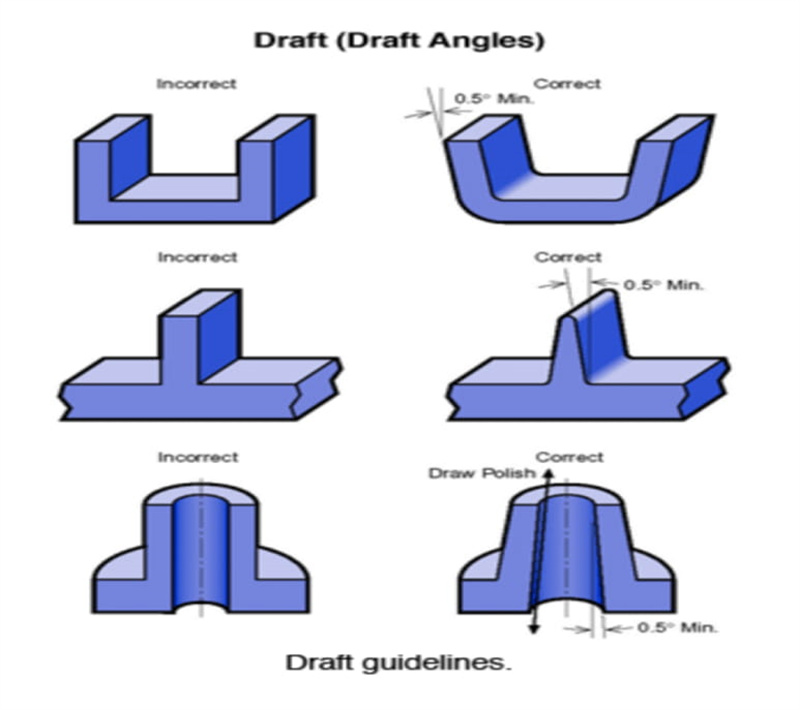

Qhov saum npoo tiav xaiv yuav tsum tau tsim nyob rau hauv lub embodiment tsim theem pib ntawm cov khoom tsim vim hais tias qhov saum npoo dictates cov khoom xaiv thiab cov cua ntsawj ntshab lub kaum sab xis, cuam tshuam tus nqi cuab yeej.Piv txwv li, ib chav kawm lossis textured tiav xav tau lub kaum sab xis tseem ceeb dua kom cov khoom tuaj yeem raug tshem tawm ntawm cov pwm.

Yog li dab tsi yog qhov tseem ceeb tshaj plaws los xav txog thaum xaiv qhov chaw tiav rau kev txhaj tshuaj molding yas?

Gloss tiav Qib A (Source:XR USA Client)

Tooling nqi

Nto tiav thiab cov khoom muaj feem cuam tshuam rau cov cuab yeej tsim thiab tus nqi, yog li xav txog thiab ntsuas qhov ua haujlwm ntawm qhov chaw ntxov ntawm tus qauv tsim.Yog tias qhov chaw ua tiav yog qhov tseem ceeb rau nws txoj haujlwm, xav txog qhov ua tiav ntawm qhov kev xav ntawm cov khoom tsim.

Ntau qhov chaw ntawm cov txheej txheem txhaj tshuaj molding tau ua tiav, tab sis polishing yog qhov tshwj xeeb.Nws tsuas yog qhov yooj yim ntawm cov duab uas tuaj yeem ua polished.Polishers tam sim no muaj cov cuab yeej zoo dua thiab cov khoom siv los ua haujlwm nrog, tab sis cov txheej txheem tseem siv zog ua haujlwm.

Lub kaum sab xis

Feem ntau qhov yuav tsum tau muaj lub kaum sab xis ntawm 1½ txog 2 Degrees

Qhov no yog ib txoj cai ntawm tus ntiv tes xoo uas siv rau cov khoom molded nrog qhov tob txog li 2 ntiv tes.Nrog rau qhov loj me no, cov cua ntsawj ntshab txog li 1½ degrees yog txaus rau kev tso tawm yooj yim ntawm cov pwm.Qhov no pab tiv thaiv kev puas tsuaj rau cov khoom thaum cov khoom siv thermoplastic shrinks.

Cov khoom siv pwm

Cov cuab yeej pwm zoo heev cuam tshuam qhov smoothness ntawm kev txhaj tshuaj molding.Lub pwm tuaj yeem tsim los ntawm ntau yam hlau, txawm hais tias hlau thiab txhuas yog cov nyiam tshaj plaws.Cov teebmeem ntawm ob cov hlau no ntawm cov khoom yas molded yog qhov sib txawv heev.

Feem ntau, cov cuab yeej hardened steel tuaj yeem tsim cov yas du tiav piv rau cov cuab yeej aluminium alloy.Yog li xav txog steel pwm yog tias cov khoom muaj qhov zoo nkauj uas yuav tsum tau muaj qhov qis ntawm qhov roughness.

Moulding khoom

Ntau hom kev txhaj tshuaj molding yas yog muaj los npog txhua yam ntawm qhov chaw thiab kev ua haujlwm.Txawm li cas los xij, tsis yog txhua lub plastics tuaj yeem ua tiav tib qhov kev txhaj tshuaj molding nto tiav.Qee cov polymers zoo dua rau kev ua kom tiav, thaum lwm tus yog qhov zoo dua rau roughening rau qhov zoo nkauj dua.

Cov tshuaj lom neeg thiab lub cev zoo sib txawv ntawm cov khoom siv tshuaj molding.Melting kub, piv txwv li, yog ib qho tseem ceeb ntawm cov khoom muaj peev xwm muab tau ib qho chaw zoo.Additives kuj muaj kev cuam tshuam rau qhov tshwm sim ntawm cov khoom tiav.Yog li ntawd, nws yog ib qho tseem ceeb rau kev ntsuam xyuas ntau yam ntaub ntawv ua ntej txiav txim siab ntawm ib qho kev ntxhib los mos.

Tsis tas li ntawd, cov khoom siv ntxiv xws li muab tub lim thiab pigments tuaj yeem cuam tshuam rau qhov kawg ntawm cov khoom molded.Cov ntxhuav hauv ntu txuas ntxiv qhia txog kev siv tau ntawm ntau cov ntaub ntawv txhaj tshuaj molding rau ntau yam SPI tiav kev xaiv.

Khoom haum rau Qib SPI-A nto tiav

| Khoom siv | A-1 | A-2 | A-3 |

| ABS | Nruab nrab | Nruab nrab | Zoo |

| Polypropylene (PP) | Tsis pom zoo | Nruab nrab | Nruab nrab |

| Polystyrene (PS) | Nruab nrab | Nruab nrab | Zoo |

| HDPE | Tsis pom zoo | Nruab nrab | Nruab nrab |

| Nylon | Nruab nrab | Nruab nrab | Zoo |

| Polycarbonate (PC) | Nruab nrab | Zoo | Zoo heev |

| Polyurethane (TPU) | Tsis pom zoo | Tsis pom zoo | Tsis pom zoo |

| Acrylic | Zoo heev | Zoo heev | Zoo heev |

Khoom haum rau Qib SPI-B nto tiav

| Khoom siv | B-1 | B-2 | B-3 |

| ABS | Zoo | Zoo | Zoo heev |

| Polypropylene (PP) | Zoo | Zoo | Zoo heev |

| Polystyrene (PS) | Zoo heev | Zoo heev | Zoo heev |

| HDPE | Zoo | Zoo | Zoo heev |

| Nylon | Zoo | Zoo heev | Zoo heev |

| Polycarbonate (PC) | Zoo | Zoo | Nruab nrab |

| Polyurethane (TPU) | Tsis pom zoo | Nruab nrab | Nruab nrab |

| Acrylic | Zoo | Zoo | Zoo |

Khoom haum rau Qib SPI-C nto tiav

| Khoom siv | C-1 | C-2 | C-3 |

| ABS | Zoo heev | Zoo heev | Zoo heev |

| Polypropylene (PP) | Zoo heev | Zoo heev | Zoo heev |

| Polystyrene (PS) | Zoo heev | Zoo heev | Zoo heev |

| HDPE | Zoo heev | Zoo heev | Zoo heev |

| Nylon | Zoo heev | Zoo heev | Zoo heev |

| Polycarbonate (PC) | Nruab nrab | Tsis pom zoo | Tsis pom zoo |

| Polyurethane (TPU) | Zoo | Zoo | Zoo |

| Acrylic | Zoo | Zoo | Zoo |

Khoom haum rau Qib SPI-D nto tiav

| Khoom siv | D-1 | D-2 | D-3 |

| ABS | Zoo heev | Zoo heev | Zoo |

| Polypropylene (PP) | Zoo heev | Zoo heev | Zoo heev |

| Polystyrene (PS) | Zoo heev | Zoo heev | Zoo |

| HDPE | Zoo heev | Zoo heev | Zoo heev |

| Nylon | Zoo heev | Zoo heev | Zoo |

| Polycarbonate (PC) | Zoo heev | Tsis pom zoo | Tsis pom zoo |

| Polyurethane (TPU) | Zoo heev | Zoo heev | Zoo |

| Acrylic | Nruab nrab | Nruab nrab | Nruab nrab |

Moulding parameters

Kev txhaj tshuaj nrawm thiab qhov kub thiab txias cuam tshuam rau saum npoo tiav rau ob peb lub laj thawj.Thaum koj muab cov kev txhaj tshuaj ceev nrawm nrog cov yaj lossis pwm kub, qhov tshwm sim yuav ua kom zoo dua qub los yog smoothness ntawm qhov chaw.Hauv qhov tseeb, kev txhaj tshuaj nrawm nrawm txhim kho tag nrho gloss thiab smoothness.Tsis tas li ntawd, kev ua kom nrawm ntawm lub pwm kab noj hniav tuaj yeem tsim cov kab tsis tshua pom pom thiab muaj qhov zoo nkauj zoo nkauj rau koj txoj haujlwm.

Kev txiav txim siab ib feem ntawm qhov chaw tiav yog qhov tseem ceeb hauv kev txhim kho tag nrho cov khoom lag luam thiab yuav tsum tau xav txog thaum lub sijhawm tsim qauv kom ua tiav cov txiaj ntsig xav tau.Koj puas tau txiav txim siab siv qhov kawg ntawm koj qhov kev txhaj tshuaj molded?

Cia Xiamen Ruicheng pab koj txiav txim siab ntawm qhov chaw tiav uas txhim kho kev zoo nkauj thiab kev ua haujlwm ntawm koj qhov chaw.

Post lub sij hawm: May-22-2023