Dab tsi yog qhov vuam kab

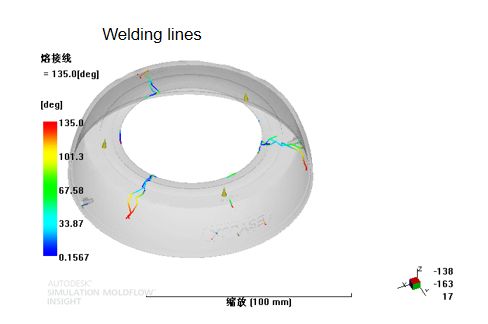

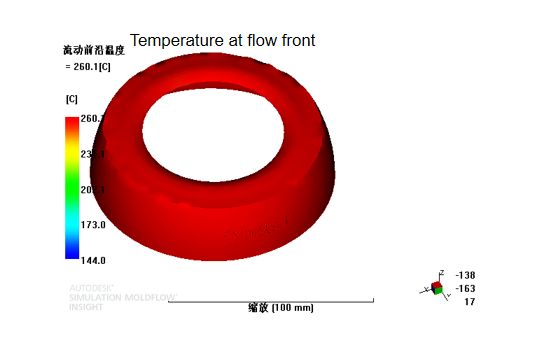

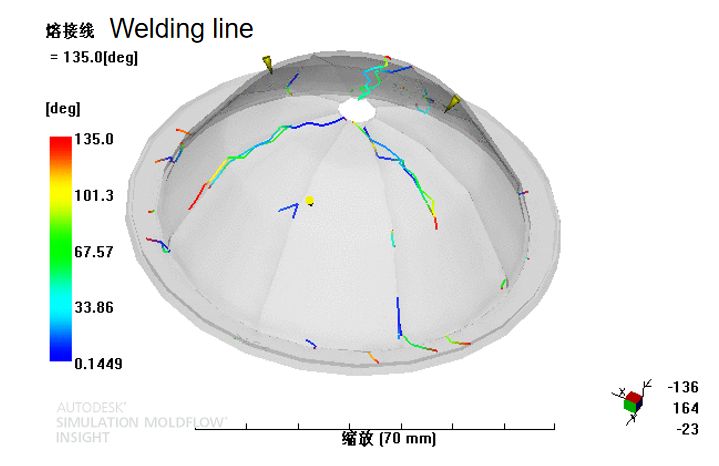

Vuam kab kuj tseem hu ua welding mark, flow mark.Nyob rau hauv cov txheej txheem txhaj tshuaj molding, thaum siv ntau lub rooj vag los yog qhov muaj nyob rau hauv cov kab noj hniav, los yog inserts thiab cov khoom uas muaj kev hloov loj nyob rau hauv thickness, qhov ntws ntawm yas yaj tshwm sim nyob rau hauv cov pwm nyob rau hauv ntau tshaj 2 cov lus qhia.Thaum ob lub melt strands sib ntsib, ib txoj kab vuam yuav raug tsim nyob rau hauv ib feem.Hais lus nruj me ntsis, yuav luag tag nrho cov khoom muaj vuam kab, thiab nws yog ib qho nyuaj rau tshem tawm tag nrho lawv, tab sis tsuas yog kom txo lawv, los yog ua rau lawv tsiv mus rau qhov chaw tsis tseem ceeb.

(Vuam kab piv txwv)

Yog vim li cas rau vuam kab tsim

Thaum lub sij hawm txias txheej txheem ntawm ob strands ntawm cov yas ntawm txoj hauj lwm ntawm lub vuam kab, yuav muaj cua ntxiab ntawm ob strands ntawm cov yas.Cov cua daig yuav cuam tshuam cov nyhuv winding ntawm polymer molecules thiab ua rau cov saw hlau molecular cais los ntawm ib leeg.

Yuav ua li cas txo txoj kab vuam

Khoom tsim thiab pwm tsim

Yog tias qhov tsos thiab kev ua tau zoo ntawm cov khoom tseem ceeb, cov neeg siv khoom thiab cov pwm tsim yuav tsum ua haujlwm ua ke, kom txo qis qhov cuam tshuam ntawm cov vuam kab kom zoo tshaj plaws.Tus neeg siv khoom / tus tsim khoom yuav tsum pab cov neeg tsim khoom kom nkag siab txog cov haujlwm tseem ceeb ntawm cov khoom thiab cov yam ntxwv tseem ceeb ntawm cov tshuaj pleev ib ce.Tus tsim pwm yuav tsum txiav txim siab txog qhov ua haujlwm thiab txoj hauv kev uas cov yas ntim tau los yog ntws mus rau hauv thiab los ntawm cov pwm thaum lub sij hawm tsim pwm, coj mus rau hauv tus account cov ntaub ntawv cuam tshuam los ntawm tus neeg siv khoom, ua kom cov pa tawm hauv qhov chaw vuam thiab txo qis. kaw cua.Tsuas yog thaum tus neeg siv khoom thiab cov pwm tsim ua haujlwm ua ke kom nkag siab txog cov khoom thiab ua haujlwm ua ke tuaj yeem xyuas kom meej tias thaj chaw uas muaj qhov vuam kab tsawg kawg nkaus los yog tshwm sim ntawm qhov tseem ceeb tshaj plaws.

Kev xaiv thiab ua cov khoom siv

Cov ntaub ntawv sib txawv muaj qhov sib txawv ntawm cov vuam kab sib txawv.Qee cov ntaub ntawv muag muag yog shear rhiab heev thiab cov kab vuam yuav tshwm sim txawm tias qhov kub ntawm qhov ntws hauv pem hauv ntej tsis cuam tshuam.Qhov no yuav xav tau kev hloov khoom siv los daws qhov teeb meem welding.

Kev txhaj tshuaj molding txheej txheem xav txog

Covtxhaj tshuaj moldingtxheej txheem kuj tuaj yeem cuam tshuam rau lub zog thiab txoj haujlwm ntawm cov kab vuam.Cov txheej txheem hloov pauv ntawm qhov kub thiab qhov siab feem ntau yuav muaj qee qhov cuam tshuam rau cov kab vuam.

Yog tias ua tau, xyuas kom tseeb tias cov kab vuam yog tsim thaum thawj theem ntawm kev txhaws.Vuam kab tsim thaum lub sij hawm packing thiab tuav theem feem ntau muaj teeb meem.Kev tsim cov vuam kab thaum lub sij hawm txhaws feem ntau yuav pab ua kom tus nqi filling, yog li txo lub sij hawm txhaws thiab nce tus nqi shear.Qhov no txo cov viscosity ntawm cov polymer thaum lub sij hawm sau cov txheej txheem, uas ua rau kom zoo winding ntawm molecular chains thiab sau yooj yim dua.

Qee lub sij hawm nce lub sij hawm ntim lossis tuav lub siab kuj yuav pab tau.Yog tias qhov tsos mob yog qhov teeb meem, qhov kev txhaj tshuaj qis dua yuav pab tau, tab sis feem ntau qhov kub ntawm pwm yuav muab tau zoo dua.Lub tshuab nqus tsev vacuum yog ib qho cuab yeej muaj zog uas tuaj yeem pab tau zoo rau cov teeb meem tshwm sim thiab lub zog.

Yog xav paub ntxivtxhaj tshuaj moldingkev paub, thov koj xav tias dawb rautiv tauj peb.

Post lub sij hawm: Dec-01-2022