Txheej txheem cej luam

Ib feem qhov kev nyab xeeb thiab qhov tseeb yog qhov tseem ceeb rau kev lag luam kho mob.Raws li kev tsim khoom siv kho mob, RuiCheng tuaj yeem muab cov khoom siv ruaj khov thiab qib kev kho mob yas txhaj tshuaj molding qhov chaw, tib lub sijhawm peb cov khoom tuaj yeem ua tau raws li cov khoom tshwj xeeb thiab cov neeg siv khoom xav tau.Kab lus no yuav qhia cov khoom siv txog kev kho mob rau koj.

Daim ntawv thov

Tam sim no, ntau yam khoom siv kho mob txhua tus ua los ntawm kev txhaj tshuaj lossis cnc tshuab.Qee yam khoom siv kho mob tau teev tseg hauv qab no:

X-ray plhaub

MRI tshuab

Catheters

Prostheses

cev

Cov khoom siv no thiab cov khoom sib txuas tuaj yeem siv tau siv ntau yam ntaub ntawv, suav nrog kev txhaj tshuaj, txhuas, titanium, PE, PVC, thiab ABS.

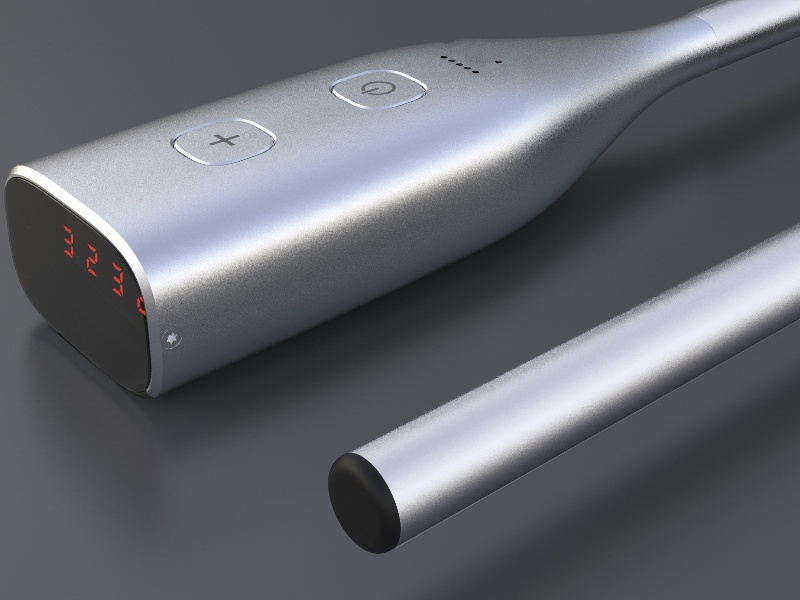

Khoom siv tes ua

CNC

Xyoo tsis ntev los no, CNC tshuab siv los siv rau hauv kev kho mob kev lag luam hauv wildly, cov chaw tsim khoom tuaj yeem tso siab rau tsim los tsimCNC pwm thiab ua rau cov khoom thaum kawg.Thaum cov khoom siv kho mob yas tuaj yeem tsim los ntawm molded, cam khwb cia, lossis extruded,CNC raws li thawj kauj ruam ntawm cov txheej txheem, nws yog feem ntau siv los tsim cov pwm los yog extrusion tuag yuav tsum tau rau cov txheej txheem ntau lawm.

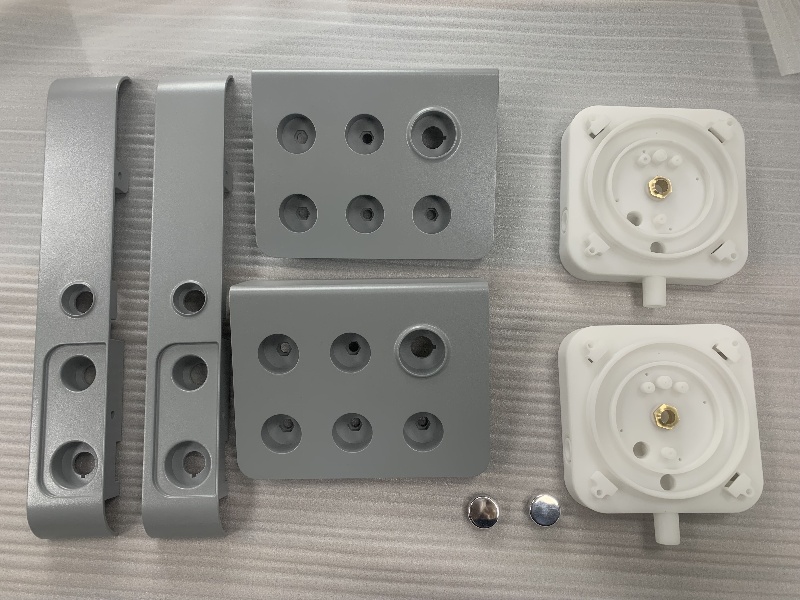

Txhaj tshuaj

Kev nce qib hauv cov txheej txheem tsim khoom thiab thev naus laus zis tau coj mus rau kev siv cov yas hauv kev lag luam niaj hnub no.Hauv kev kho mob thiab kev lag luam tshuaj, cov yas feem ntau siv nrog cov txheej txheem txhaj tshuaj molding los tsim cov qauv thiab cov khoom siv tag nrho ntawm cov cuab yeej kho mob thiab cov khoom siv.Raws li cov ntaub ntawv yas tshiab thiab cov qauv tsim tau tsim, cov yas txhaj tshuaj molded tau nce ntxiv kom txo cov kab mob sib kis, tswj kev mob zoo dua, thiab txo nqi kho mob.

Khoom siv

1. yas

Cov txheej txheem txhaj tshuaj molding haum rau ntau yam ntawm cov ntaub ntawv yas, ua kom nws zoo tsim los tsim cov khoom kho mob thiab tshuaj los ntawm txhua yam kev kho mob-qib yas yuav tsum tau ua rau qhov project.Muaj ntau cov yas tsim nyog rau kev kho mob kev txhaj tshuaj molding, txhua tus muaj cov khoom tshwj xeeb thiab cov yam ntxwv ua haujlwm.Cov khoom siv yas uas siv rau kev txhaj tshuaj molding muaj xws li: Polyethylene, Polypropylene, Polystyrene, Polycarbonate.

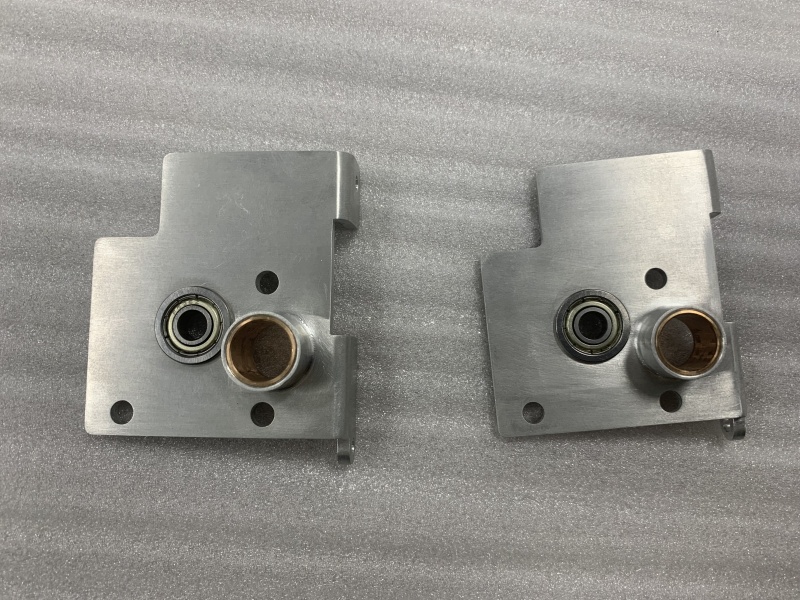

2. Hlau

Txhua yam khoom siv tau pom zoo rau cov cuab yeej kho mob yuav tsum ua tau raws li cov qauv kev ntseeg siab thiab kev ua tau zoo.Hauv qab no yog qee cov ntaub ntawv siv rau kev kho mob CNC machining:

• Aluminium

Aluminium feem ntau yog siv rau hauv kev lag luam kho mob vim nws lub teeb yuag, siab zog-rau-hnyav piv, durability, thiab corrosion kuj.Nws kuj yog biocompatible thiab tuaj yeem siv rau kev siv sab hauv hauv tib neeg lub cev.

• Stainless hlau

Stainless hlau cov khoom tsim nyog suav nrog lub zog, toughness, corrosion resistance, impact resistance, thiab biocompatibility ua rau nws zoo tagnrho rau ntau siv hauv kev kho mob kev lag luam.Nws cov thermal stability thiab txheej txheej passivation sab nraud tso cai rau cov khoom kom huv thiab ntxuav tau yooj yim.

•Titanium thiab Titanium Alloys

Titanium thiab nws cov alloys yog siv nyob rau hauv kev kho mob kev lag luam vim lawv lub zog, tsis tshua muaj hnyav thiab ceev, thiab corrosion kuj.Titanium yog ib qho ntawm ob peb cov hlau tsis muaj zog thiab tsis cuam tshuam los ntawm lub cev thiab cov ntaub so ntswg.

•Brass Polyethylene (PE)

Polyethylene (PE) feem ntau yog siv rau hauv kev kho mob vim nws muaj peev xwm khaws cov qauv kev ncaj ncees txawm tias tom qab ob peb lub voj voog kev huv thiab kev lom neeg tsis zoo.Xometry tuaj yeem ua ob qho tib si ncaj qha tshuab PE rau cov khoom tiav thiab ntau yam khoom siv yas uas xav tau los tsim cov khoom.

• Polyvinyl Chloride (PVC)

Polyvinyl chloride (PVC) yog cov khoom siv zoo tshaj plaws rau kev siv hauv kev kho mob.Qee yam ntawm nws cov khoom tsim nyog muaj xws li nplaim taws, tshuaj tiv thaiv, thiab kav ntev.

Xav kawm ntxiv?

Txhawm rau pom cov khoom lag luam ntawm peb cov haujlwm hauv kev lag luam kho mob, tshawb xyuas cov ntaub ntawv tshawb fawb no uas peb tau ua cov pwm tsim rau aABS TEST TUB.

Tiv tauj peb!Koj tseem yuav kawm txog peb cov peev xwm kev cai li cas.

Post lub sij hawm: Mar-28-2024