Thaum lub sij hawm txhaj tshuaj molding txheej txheem, nws yog ib qho uas yuav ntsib ntau yam tsis xws luag nyob rau hauv molded qhov chaw, uas yuav cuam tshuam qhov zoo thiab kev ua tau zoo ntawm cov khoom.Kab lus no yog txhawm rau tshawb nrhiav qee qhov tsis xws luag hauv kev txhaj tshuaj molded qhov chaw thiab sib tham txog txoj hauv kev los daws cov teeb meem no.

1.Flow Marks:

Flow kab yog cov khoom siv kho kom zoo nkauj uas muaj cov kab tawm xim, streaks, lossis cov qauv uas pom ntawm qhov chaw ntawm qhov molded.Cov kab no tshwm sim thaum cov yas molten txav ntawm qhov sib txawv nrawm thoob plaws hauv kev txhaj tshuaj pwm, uas ua rau muaj qhov sib txawv ntawm cov resin solidification.Cov kab ntws feem ntau yog qhov qhia txog kev txhaj tshuaj tsawg thiab / lossis siab.

Tsis tas li ntawd, cov kab ntws tuaj yeem tshwm sim thaum cov thermoplastic resin ntws los ntawm thaj chaw ntawm cov pwm nrog cov phab ntsa sib txawv.Yog li ntawd, kev tswj xyuas cov phab ntsa tuab tuab thiab ua kom qhov ntev ntawm cov chamfers thiab fillets yog qhov tseem ceeb kom txo qis qhov tshwm sim ntawm cov kab ntws.Lwm qhov kev ntsuas tau zoo yog tso lub rooj vag rau hauv ib qho nyias-walled seem ntawm cov cuab yeej kab noj hniav, uas yuav pab txo qhov tsim ntawm cov kab khiav.

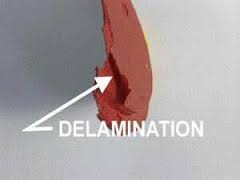

2. Nto Delamination:

Delamination yog hais txog kev sib cais ntawm nyias txheej ntawm ib feem, zoo li cov coatings peelable.Qhov xwm txheej no tshwm sim vim muaj cov kab mob tsis sib haum xeeb hauv cov khoom, ua rau muaj qhov tsis zoo hauv cheeb tsam.Delamination kuj tuaj yeem tshwm sim los ntawm kev cia siab ntau dhau ntawm cov pwm tso tawm cov neeg ua haujlwm.

Txhawm rau hais thiab tiv thaiv delamination, nws raug nquahu kom nce pwm kub thiab ua kom zoo dua cov pwm ejection system kom txo qis kev cia siab ntawm pwm tso tawm cov neeg ua haujlwm, vim tias cov neeg ua haujlwm no tuaj yeem ua rau delamination.Tsis tas li ntawd, ua ntej ziab ntawm cov yas ua ntej molding tuaj yeem pab tiv thaiv delamination.

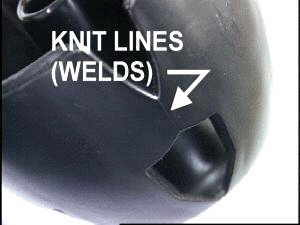

3.Knit kab:

Knit kab, tseem hu ua weld kab, yog qhov tsis xws luag uas tshwm sim thaum ob qhov ntws ntawm molten resin converge thaum lawv txav mus los ntawm cov pwm geometry, tshwj xeeb tshaj yog nyob ib ncig ntawm thaj chaw nrog qhov.Thaum cov yas ntws thiab qhwv ib ncig ntawm txhua sab ntawm ib lub qhov, ob qhov ntws sib ntsib.Yog hais tias qhov kub ntawm cov molten resin tsis zoo, ob qhov ntws yuav ua tsis tau zoo, ua rau pom cov kab vuam.Qhov no weld kab diminishes tag nrho lub zog thiab durability ntawm cov khoom.

Txhawm rau tiv thaiv cov txheej txheem ntxov ntxov, nws yog qhov zoo los ua kom qhov kub thiab txias ntawm cov molten resin.Tsis tas li ntawd, tsa qhov kev txhaj tshuaj nrawm thiab siab tuaj yeem pab txo qhov tshwm sim ntawm cov kab knit.Resins nrog qis viscosity thiab qis melting cov ntsiab lus tsis tshua muaj kev cuam tshuam rau kev sib txuas kab tsim thaum txhaj tshuaj molding.Tsis tas li ntawd, tshem tawm cov partitions los ntawm pwm tsim tuaj yeem tshem tawm qhov tsim ntawm cov kab.

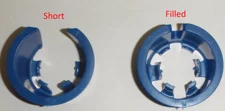

4. Short Shots:

Kev txhaj tshuaj luv luv tshwm sim thaum cov resin tsis ua kom tiav cov pwm kab noj hniav, ua rau cov khoom tsis tiav thiab siv tsis tau.Ntau yam tuaj yeem ua rau luv luv txhaj tshuaj molding.Cov laj thawj feem ntau suav nrog kev txwv tsis pub khiav hauv pwm, uas tuaj yeem raug ntaus nqi los ntawm nqaim lossis thaiv cov rooj vag, lub hnab ntim cua, lossis tsis txaus txhaj tshuaj.Cov khoom viscosity thiab pwm kub kuj tuaj yeem ua rau kev txhaj tshuaj luv luv.

Txhawm rau tiv thaiv qhov tshwm sim ntawm kev txhaj tshuaj luv luv, nws yog qhov zoo los ua kom cov pwm kub, vim qhov no tuaj yeem txhim kho resin txaus.Tsis tas li ntawd, kev sib txuas ntxiv qhov cua nkag mus rau hauv cov pwm tsim tso cai rau cov cua nkag kom khiav tau zoo dua.Los ntawm kev hais txog cov xwm txheej no, qhov tshwm sim ntawm kev txhaj tshuaj luv luv hauv kev txhaj tshuaj molding tuaj yeem txo qis.

5. Warping:

Warping hauv kev txhaj tshuaj molding yog hais txog qhov tsis xav tau kev sib tw lossis khoov rau hauv ib feem uas tshwm sim los ntawm qhov tsis sib xws hauv lub ntsws thaum lub caij txias.Qhov kev tsis zoo no feem ntau tshwm sim los ntawm qhov tsis sib xws lossis tsis sib haum pwm txias, ua rau muaj kev ntxhov siab sab hauv hauv cov khoom siv. Txhawm rau tiv thaiv kev tsis sib haum xeeb hauv kev txhaj tshuaj molding, nws yog ib qho tseem ceeb los xyuas kom meej tias cov khoom tau txias txaus ntawm tus nqi maj mam, tso sijhawm txaus. rau cov khoom kom txias uniformly.Kev tuav cov phab ntsa tuab hauv cov pwm tsim yog qhov tseem ceeb rau ntau qhov laj thawj, nrog rau kev ua kom yooj yim ntawm cov yas ntws los ntawm cov pwm kab noj hniav kom zoo ib yam.Los ntawm kev siv cov tswv yim txias kom zoo thiab tsim cov pwm nrog cov phab ntsa tuab, qhov kev pheej hmoo ntawm warpage tsis xws luag hauv Kev txhaj tshuaj molding tuaj yeem txo qis, ua rau cov khoom zoo thiab qhov ruaj khov.

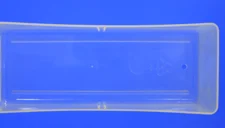

6.Jetting:

Jetting tsis xws luag hauv kev txhaj tshuaj molding tuaj yeem tshwm sim thaum cov txheej txheem solidification tsis sib npaug.Jetting tshwm sim thaum thawj zaug resin dav hlau nkag mus rau hauv pwm thiab pib ua kom khov ua ntej cov kab noj hniav puv tag.Qhov no ua rau pom cov qauv squiggly ntws ntawm qhov chaw thiab txo nws lub zog.

Txhawm rau tiv thaiv jetting tsis xws luag, nws raug nquahu kom txo qhov kev txhaj tshuaj siab, kom ntseeg tau tias cov pwm ua tiav ntau dua.Ua kom cov pwm thiab resin kub tuaj yeem pab tiv thaiv kom tsis txhob ntxov ntxov ntawm cov jets resin.Tsis tas li ntawd, tso lub qhov rooj txhaj tshuaj rau hauv txoj hauv kev uas coj cov khoom ntws los ntawm qhov luv tshaj plaws ntawm cov pwm yog ib txoj hauv kev zoo rau kev txo qis.

Los ntawm kev ua raws li cov kev ntsuas no, kev pheej hmoo ntawm jetting tsis xws luag hauv kev txhaj tshuaj molding tuaj yeem raug txo, ua rau kev txhim kho saum npoo zoo thiab txhim kho ib feem ntawm lub zog.

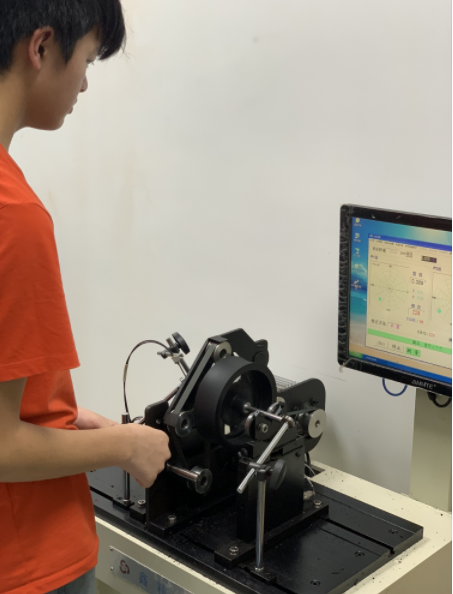

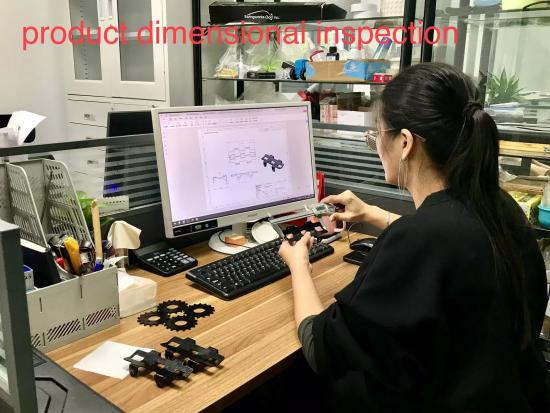

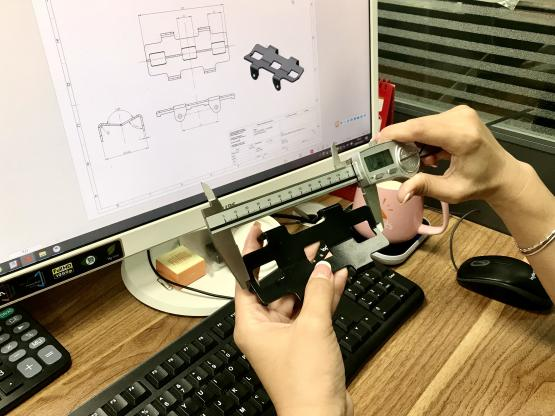

Peb lub tuam txhab siv ntau yam kev ntsuas los tiv thaiv kev txhaj tshuaj molding tsis xws luag thiab xyuas kom zoo zoo txhaj tshuaj molded qhov chaw.Cov yam tseem ceeb muaj xws li xaiv cov khoom zoo tshaj plaws, kev tsim pwm zoo, kev tswj xyuas cov txheej txheem, thiab kev tswj xyuas nruj.Peb pab neeg tau txais kev cob qhia kev cob qhia thiab txuas ntxiv txhim kho thiab txhim kho cov txheej txheem ntau lawm.

Peb lub tuam txhab siv ntau yam kev ntsuas los tiv thaiv kev txhaj tshuaj molding tsis xws luag thiab xyuas kom zoo zoo txhaj tshuaj molded qhov chaw.Cov yam tseem ceeb muaj xws li xaiv cov khoom zoo tshaj plaws, kev tsim pwm zoo, kev tswj xyuas cov txheej txheem, thiab kev tswj xyuas nruj.Peb pab neeg tau txais kev cob qhia kev cob qhia thiab txuas ntxiv txhim kho thiab txhim kho cov txheej txheem ntau lawm.

Peb lub tuam txhab ua kom cov khoom zoo los ntawm kev ua raws li ISO 9001 kev tswj xyuas qhov zoo.Peb tau tsim kom muaj kev tswj xyuas zoo nrog cov txheej txheem thiab cov txheej txheem.Peb txhawb kom cov neeg ua haujlwm koom nrog thiab muab kev cob qhia thiab kev kawm.Los ntawm cov kev ntsuas no, peb lav tias peb cov khoom xa tuaj tau zoo heev thiab ua tau raws li cov neeg xav tau.

Kev xaiv rau tus neeg tsim khoom lag luam xws li Xiaenruicheng, uas muaj kev paub dav dav ntawm kev txhaj tshuaj molding tsis xws luag thiab lawv cov kev daws teeb meem, tuaj yeem ua rau muaj kev cuam tshuam loj rau cov txiaj ntsig ntawm koj qhov project.Nws tuaj yeem yog qhov kev txiav txim siab ntawm qhov tau txais cov khoom zoo, xa tawm raws sijhawm thiab nyob rau hauv kev siv nyiaj, lossis ntsib teeb meem xws li cov kab sib txuas, jetting, flash, cov cim dab dej, thiab lwm yam tsis zoo.Dhau li ntawm peb cov kws tshaj lij ua lub khw tsim khoom raws li qhov xav tau, peb kuj muaj kev sib tham tsim thiab kev pabcuam zoo.Qhov no ua kom ntseeg tau tias peb pab txhua pab pawg hauv kev tsim kom muaj kev ua haujlwm zoo, ua kom zoo nkauj, thiab ua haujlwm siab nrog qhov ua tau zoo tshaj plaws.Hu rau peb hnub no los tshawb txog peb cov kev txhaj tshuaj molding kev daws teeb meem.

Post lub sij hawm: Dec-15-2023