Stamping yog txheej txheem kev tsim khoom siv los tsim cov ntawv hlau los yog ib daim hlab los ntawm kev siv lub zog los ntawm kev tuag los yog kev tuag.Nws suav nrog kev siv xovxwm, uas siv lub siab rau cov khoom siv hlau, ua rau nws deform thiab coj mus rau qhov zoo li ntawm qhov tuag.

Dab tsi yog cov txheej txheem ntawm stamping?

① Tsim thiab Engineering: Cov txheej txheem pib nrog kev tsim thiab kev tsim vaj tsev ntawm qhov chaw stamped.Qhov no suav nrog kev tsim cov ntu geometry, txiav txim siab cov khoom siv tshwj xeeb, thiab tsim cov tuag thiab cov cuab yeej xav tau rau txheej txheem stamping.

② Kev Npaj Cov Khoom Siv: Cov ntawv hlau lossis cov strips, lub npe hu ua cov khoom lag luam lossis cov khoom seem, tau npaj rau txheej txheem stamping.Qhov no yuav cuam tshuam txog kev txiav cov khoom lag luam rau hauv qhov loj me thiab cov duab kom haum rau cov tuag thiab tshem tawm cov kab mob los yog qhov tsis zoo.

③ Kev teeb tsa tuag: Cov tuag, uas muaj cov punch thiab cov kab noj hniav tuag, raug ntsia rau hauv cov xovxwm stamping.Cov tuag yog precisely aligned thiab securely clamped nyob rau hauv qhov chaw los xyuas kom meej meej thiab zoo ib yam stamping.

④ Kev pub mis: Cov khoom lag luam yog pub rau hauv cov ntawv xovxwm stamping, manually lossis txiav.Lub tshuab pub mis ua kom ntseeg tau tias cov khoom lag luam zoo nyob hauv qab qhov tuag rau txhua lub voj voog stamping.

⑤ Kev Ua Haujlwm Stamping: Cov xovxwm stamping siv ntau lub zog rau cov khoom siv, ua rau nws deform thiab ua rau lub cev tuag.Cov kauj ruam no feem ntau suav nrog ib lossis ntau qhov kev ua haujlwm, xws li blanking (txiav tawm cov duab uas xav tau), khoov (tsim cov ces kaum los yog nkhaus), kos duab (stretching cov khoom mus rau hauv ib txoj kev sib sib zog nqus), los yog tsim (tsim tshwj xeeb nta lossis qauv).

⑥ Kev tshem tawm ib feem: Tom qab kev ua haujlwm stamping tiav, qhov seem stamped raug tshem tawm ntawm qhov tuag.Qhov no tuaj yeem ua tau manually lossis nrog kev pab ntawm automation, xws li caj npab robotic lossis conveyor systems.

⑦ Kev Ua Haujlwm Thib Ob: Nyob ntawm qhov kev xav tau tshwj xeeb ntawm ntu, kev ua haujlwm theem nrab ntxiv tuaj yeem ua.Cov no tuaj yeem suav nrog kev deburring (tshem tawm cov npoo ntse lossis burrs), nto tiav (xws li polishing lossis txheej), sib dhos, lossis kev tshuaj xyuas zoo.

⑧ Kev Tshuaj Xyuas Zoo: Cov khoom siv stamped raug kuaj xyuas kom ntseeg tau tias lawv ua tau raws li cov qauv kev cai.Qhov no tuaj yeem suav nrog kev ntsuas qhov ntev, kev tshuaj xyuas qhov muag, kuaj cov khoom siv, lossis lwm cov txheej txheem tswj kom zoo.

⑨ Ntim thiab Shipping: Thaum cov khoom stamped dhau qhov kev kuaj xyuas zoo, lawv tau ntim raws li cov kev cai tshwj xeeb thiab npaj rau kev xa khoom lossis kev ua haujlwm ntxiv.

Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias cov txheej txheem cov kauj ruam yuav txawv nyob ntawm qhov nyuaj ntawm ib feem, txoj kev xaiv stamping, thiab lwm yam tshwj xeeb rau kev tsim khoom.

Saib Dab Tsi Ua Stamping Thiaj Nrov

Nqi-zoo: Stamping muab cov nqi zoo vim nws cov kev ua haujlwm siab.Cov txheej txheem tso cai rau kev ua haujlwm sai thiab ua haujlwm ntawm cov khoom loj ntawm cov khoom, txo cov nqi zog thiab ua kom tag nrho cov nqi-zoo.

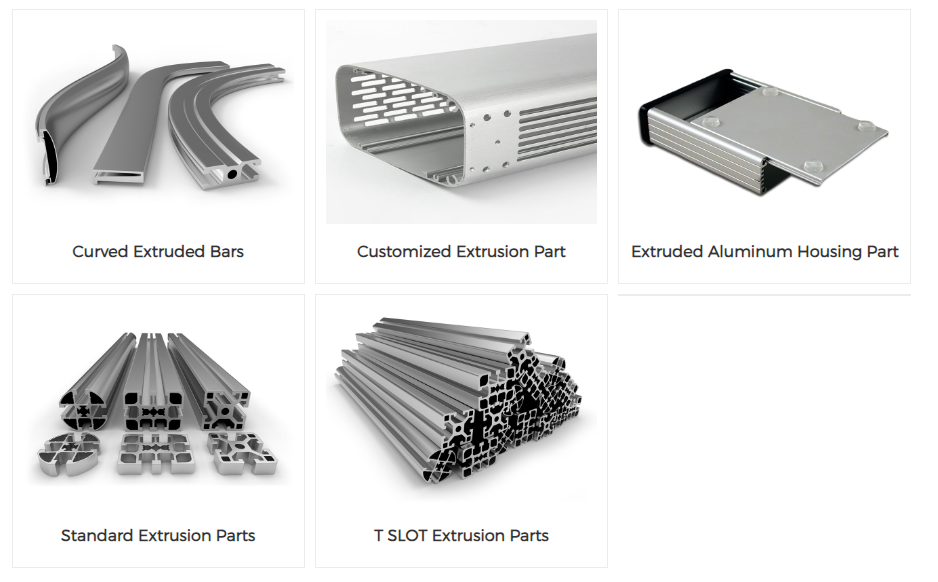

Material Compatibility: Stamping tuaj yeem siv rau ntau yam ntaub ntawv, suav nrog hlau (xws li steel, aluminium, thiab tooj liab) thiab qee cov yas.Qhov kev hloov pauv no tso cai rau cov tuam txhab xaiv cov khoom tsim nyog tshaj plaws rau lawv cov kev thov tshwj xeeb, xav txog yam xws li lub zog, durability, thiab conductivity.

High Precision: Stamping txheej txheem tuaj yeem ua tiav qib siab ntawm qhov raug thiab rov ua dua.Los ntawm kev siv cov cuab yeej siv qib siab thiab kev tuag thev naus laus zis, cov khoom raug thiab zoo ib yam tuaj yeem tsim tau, ua tau raws li kev ua siab ntev thiab cov qauv zoo.

Ceev thiab Ua Haujlwm: Kev ua haujlwm stamping feem ntau yog ceev thiab ua haujlwm tau zoo.Nrog automated pub thiab xovxwm tshuab, stamping tuaj yeem ua tiav cov nqi ntau lawm, txo cov sij hawm txhuas thiab ua kom tag nrho cov khoom tsim tau.

Strength and Durability: Stamped parts feem ntau muaj cov khoom siv zoo heev, suav nrog lub zog, nruj, thiab kav ntev.Lub deformation thiab ua hauj lwm hardening uas tshwm sim thaum lub sij hawm stamping txheej txheem txhim kho cov txheej txheem kev ncaj ncees ntawm cov khoom, ua rau lawv tsim nyog rau kev thov.

Scalability: Stamping tuaj yeem ua raws li qhov xav tau ntawm cov khoom ntim qis thiab siab.Nws yog qhov zoo rau kev tsim khoom loj vim nws qhov kev kub ceev, cov txheej txheem automated.Nyob rau tib lub sijhawm, nws kuj tuaj yeem hloov kho rau kev tsim khoom me me los yog kev tsim qauv, muab kev yooj yim hauv kev ua kom tau raws li cov kev xav tau sib txawv.

Kev koom ua ke nrog lwm cov txheej txheem: Stamping tuaj yeem yooj yim sib xyaw nrog lwm cov txheej txheem tsim khoom xws li vuam, sib dhos, thiab ua kom tiav.Qhov no tso cai rau streamlined ntau lawm workflows thiab creation ntawm complex sib dhos los yog tiav cov khoom.

Thaum xaiv cov txheej txheem stamping raws li qhov tseeb, ntau yam yuav tsum tau xav txog:

Khoom siv: Txheeb xyuas hom hlau lossis alloy yuav tsum tau stamped.Cov hlau sib txawv muaj cov yam ntxwv thiab cov khoom sib txawv, xws li lub zog, ductility, thiab thickness.Xav txog cov kev cai tshwj xeeb ntawm ib feem lossis cov khoom lag luam thiab xaiv cov txheej txheem stamping uas haum rau cov khoom xaiv.

Complexity ntawm Part: Ntsuas qhov complexity ntawm ib feem los yog cov khoom tsim.Txiav txim siab yog tias nws muaj cov duab zoo sib xws, khoov, lossis nta xws li embossing lossis tho.Txawv stamping txheej txheem, xws li blanking, dabtsi yog khoov, los yog sib sib zog nqus daim duab, yog haum rau ntau hom geometries.

Qhuav Volume: Xav txog qhov yuav tsum tau ntim ntau lawm.Cov txheej txheem stamping tuaj yeem hloov kho rau ob qho tib si ntim qis thiab ntim ntau lawm.Rau cov khoom ntim siab, kev nce qib tuag stamping lossis hloov stamping tuaj yeem tsim nyog, thaum lub ntim qis lossis cov qauv tsim, ib-theem lossis compound tuag stamping tuaj yeem siv.

Tolerance thiab Precision: Ntsuam xyuas qhov yuav tsum tau muaj qhov raug thiab kam rau ua ntawm qhov chaw stamped.Qee cov txheej txheem stamping, xws li nplua blanking lossis precision stamping, tuaj yeem ua tiav nruj dua thiab siab dua piv rau cov txheej txheem stamping.Xav txog qib ntawm precision yuav tsum tau rau ib feem los yog cov khoom.

Surface Finish: Ntsuam xyuas qhov xav tau qhov chaw tiav ntawm qhov chaw stamped.Cov txheej txheem stamping tej zaum yuav tawm cov qhab nia lossis xav tau cov kauj ruam ntxiv kom ua tiav qhov zoo ntawm qhov chaw.Xav txog yog tias yuav tsum tau ua haujlwm thib ob xws li deburring lossis polishing.

Cov cuab yeej thiab cov cuab yeej siv: Ntsuas qhov muaj thiab tus nqi ntawm cov cuab yeej thiab cov cuab yeej xav tau rau txheej txheem stamping.Cov txheej txheem stamping sib txawv yuav xav tau kev tuag tshwj xeeb, xuas nrig ntaus, lossis khoom siv xovxwm.Xav txog lub sij hawm ua tus thawj coj thiab tus nqi ntawm cov cuab yeej, nrog rau qhov muaj peev xwm tau txais lossis hloov kho cov cuab yeej tsim nyog.

Nqi thiab Efficiency: Ntsuam xyuas tag nrho cov nqi-zoo thiab efficiency ntawm cov txheej txheem stamping.Xav txog yam xws li cov nqi ntawm cov khoom siv, cov nqi siv, lub sij hawm ntau lawm, kev siv hluav taws xob, thiab kev ua haujlwm.Sib piv qhov zoo thiab cov kev txwv ntawm cov txheej txheem stamping sib txawv los txiav txim siab qhov kev xaiv zoo tshaj plaws rau cov kev tsim khoom tshwj xeeb.

Los ntawm kev ua tib zoo xav txog cov xwm txheej no thiab sab laj nrog cov kws tshaj lij hauv kev lag luam stamping, xws li Xiaenruicheng, koj tuaj yeem txiav txim siab paub thiab xaiv cov txheej txheem stamping tsim nyog tshaj plaws rau koj qhov xwm txheej tshwj xeeb.

Post lub sij hawm: Feb-21-2024