Kev sib raug zoo ntawm cov yas txhaj tshuaj pwm thiab shrinkage tus nqi yog complex thiab cuam tshuam los ntawm ntau yam, xws li:

1.Khoom siv:Cov yas sib txawv muaj qhov sib txawv shrinkage tus nqi, uas tuaj yeem nyob ntawm 0.5% mus rau 2% uas muaj kev cuam tshuam loj rau qhov raug thiab qhov zoo ntawm qhov kawg.Nov yog qee qhov piv txwv ntawm cov ntaub ntawv yas nrog lawv cov nqi shrinkage:

2.Polyethylene (PE):PE muaj qhov qis qis ntawm 0.5% mus rau 1%.Qhov no ua rau nws zoo rau cov ntawv thov uas qhov kev ruaj ntseg yog qhov tseem ceeb, xws li ntim khoom thiab cov khoom siv.

Polypropylene (PP):PP muaj ib tug nruab nrab shrinkage tus nqi ntawm 0.8% mus rau 1.5%.Cov khoom no yog dav siv rau ntau yam kev siv, nrog rau cov khoom siv hauv tsev, ntim khoom, thiab cov khoom siv tsheb.

Acrylonitrile-Butadiene-Styrene (ABS):ABS muaj qhov qis qis qis ntawm 1% txog 1.5%.Cov khoom siv no feem ntau yog siv rau hauv cov ntawv thov uas yuav tsum tau muaj kev cuam tshuam, toughness, thiab seem stability, xws li cov khoom ua si, electronics, thiab automotive qhov chaw.

Nylon (PA):Nylon muaj qhov shrinkage siab ntawm 1.5% mus rau 2%.Cov khoom siv no feem ntau yog siv rau hauv cov ntawv thov kev ntxhov siab, xws li lub zog thiab cov kabmob, thiab hauv cov ntawv thov uas qhov kev ruaj ntseg tsis yog qhov tseem ceeb.

2, Phab ntsa thickness:

Phab ntsa thickness yog ib qho tseem ceeb uas yuav cuam tshuam rau shrinkage hauv yas txhaj tshuaj molding.Nov yog li cas:

Cov phab ntsa Thicker yuav muaj cov nqi shrinkage ntau dua,raws li cov khoom siv ntau dua yuav tsum tau ua kom tiav cov pwm, ua rau muaj kev sib zog ntau dua.Lub thickness ntawm phab ntsa, lub sij hawm ntau nws yuav siv sij hawm rau cua sov kom dissipate, uas yuav ua rau ib tug qeeb qeeb qeeb thiab shrinkage ntau dua.

Cov phab ntsa tsis sib xws tuaj yeem ua rau tsis sib xws, raws li qhov sib txawv ntawm qhov yuav txias thiab khov ntawm cov nqi sib txawv.Qhov no tuaj yeem ua rau warping, distortion, thiab lwm yam tsis raug ntawm qhov kawg.

Txhawm rau txo qis qis thiab ua tiav qhov zoo sib xws, cov khoom zoo, feem ntau yuav tsum tau ua kom zoo dua cov phab ntsa thickness faib thiab siv cov txheej txheem tswj xws li kev tswj kub, kev txhaj tshuaj qeeb, thiab sib npaug ntawm cov pwm kab noj hniav.Tsis tas li ntawd, cov cuab yeej simulation, xws li finite element tsom xam (FEA), tuaj yeem siv los kwv yees qhov shrinkage thiab ua kom zoo dua cov pwm tsim kom txo nws qhov cuam tshuam rau qhov zoo.

3, Ntu geometry:

Lub geometry ntawm ib feem yas tuaj yeem muaj qhov cuam tshuam loj rau qhov shrinkage vim nws cuam tshuam rau txoj kev uas cov yas ntws, txias, thiab solidifies hauv nws cov pwm.

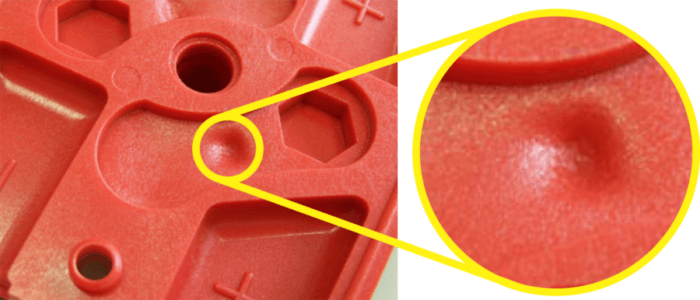

Complex geometries: Cov khoom uas muaj cov geometries complex, xws li undercuts, sib sib zog nqus hnab tshos, thiab nkhaus, tuaj yeem ua rau thaj chaw uas cov yas ntim khoom thiab tsis tuaj yeem ua kom sib npaug.Qhov no tuaj yeem ua rau cov nqi qis dua hauv cov cheeb tsam no thiab tuaj yeem ua rau warping, distortion, thiab lwm yam tsis raug ntawm qhov kawg ntawm qhov kawg.

Cov khoom ntws: Txoj kev uas cov yas ntws mus rau hauv thiab ntim cov pwm tuaj yeem cuam tshuam los ntawm ib feem geometry.Yog tias cov yas tsis ntws sib npaug mus rau txhua qhov chaw ntawm cov pwm, nws tuaj yeem ua rau cov nqi qis dua hauv qee qhov chaw.

Txias tus nqi: Cov cua txias ntawm cov yas kuj cuam tshuam los ntawm qhov chaw geometry.Nyob rau hauv cov cheeb tsam uas nyuaj geometries, cov yas yuav siv sij hawm ntev dua kom txias thiab solidify, uas yuav ua rau kom shrinkage ntau dua.

4, pwm kub:

Qhov kub ntawm pwm cuam tshuam tus nqi ntawm cov yas txias thiab solidifies.Cov pwm kub ntau dua tuaj yeem ua rau qeeb qeeb qeeb, uas tuaj yeem ua rau kom muaj zog.Conversely, qis pwm kub tuaj yeem ua rau cov cua txias sai dua, uas tuaj yeem txo qis qis tab sis kuj tseem tuaj yeem ua rau muaj kev kub ntxhov thiab lwm qhov tsis raug ntawm qhov kawg.

Xiamen Ruicheng muaj ntau pab neeg ua haujlwm paub txog kev txhaj tshuaj pwmuas koom nrog kev siv cov txheej txheem tswj, xws li kev tswj qhov kub thiab txias ntawm pwm sensors, nrog rau kev ua kom zoo dua cov pwm tsim thiab kev ua haujlwm kom ntseeg tau tias qhov txias txias thiab zoo ib yam.

Xiamen Ruicheng ceeb toom: kev ceev faj prototyping thiab kev sim tuaj yeem pab txheeb xyuas cov teeb meem muaj peev xwm thiab ua kom zoo dua cov pwm tsim kom zoo ib yam, cov khoom zoo.

Post lub sij hawm: Feb-14-2023