Warpage deformation yog hais txog qhov tsis sib xws ntawm cov duab ntawm cov khoom txhaj tshuaj molded thiab warpage, deviating los ntawm cov duab raug qhov yuav tsum tau ntawm ib feem, nws yog ib qho tsis xws luag los daws qhov kev txhaj tshuaj pwm tsim thiab ntau lawm.

Dab tsi ua rau cov teeb meem thiab yuav ua li cas txhim khonws?

Cov qauv ntawm cov pwm, cov khoom siv thermophysical ntawm cov khoom siv yas thiab cov xwm txheej thiab cov txheej txheem molding txhua tus muaj qhov sib txawv ntawm kev cuam tshuam ntawm kev ua tsov rog thiab deformation ntawm cov khoom.

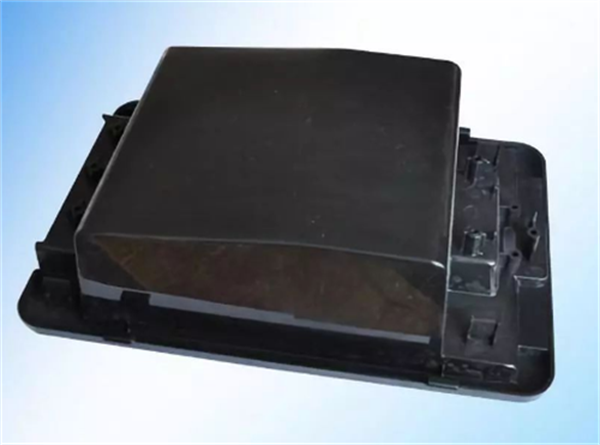

1. Pwm tsis xws luag

Kev tsim cov pwm txiav txim siab qhov kev xav ntawm kev sib tw ntawm ib feem, thiab nws yog qhov nyuaj heev rau kev txwv qhov kev nyiam no los ntawm kev hloov cov pwm pwm, yog li qhov kev daws teeb meem kawg yuav tsum pib los ntawm pwm tsim thiab txhim kho.

(1) Txhim kho cov pwm kom cov tuab thiab qhov zoo ntawm qhov zoo sib xws.

(2) kev tsim cov cua txias kom cov pwm kab noj hniav kub tsis sib xws nyob rau hauv txhua qhov chaw, tsim nyog thickening ntawm qhov nyuaj rau tsim ib feem ntawm lub manifold, lub ntsiab ntws channel, shorten lub ntws nrug, kom deb li deb li deb li sai tau tshem tawm cov kab noj hniav sib txawv, siab sib txawv, kub sib txawv.

(3) Qhov chaw hloov pauv thiab cov fab ntawm lub thickness ntawm ib feem yuav tsum du txaus thiab muaj cov pwm tso tawm zoo, xws li nce qhov tso tawm, txhim kho polishing ntawm pwm nto, txo cov thickness ntawm cov txheej khov thaum sau pwm. , txo cov kev ntxhov siab sab hauv thiab ua kom qhov sib npaug ntawm cov ejector system.

(4) Ua kom muaj qhov cua zoo.

(5) Ua kom cov phab ntsa tuab ntawm cov ntu los yog ua kom muaj kev tiv thaiv kev tiv thaiv, los ntawm kev ntxiv dag zog rau lub zog los txhim kho qhov kev tiv thaiv warp.

2. Kev tswj tsis raug ntawm kev ua thiab molding tej yam kev mob

Nyob rau hauv cov txheej txheem txhaj tshuaj molding, molten yas nyob rau hauv lub txhaj tshuaj molding theem vim yog cov txheej txheem ntawm cov polymer molecules raws li cov kev taw qhia ntws kom cov yas nyob rau hauv lub ntws kev taw qhia ntawm lub shrinkage npaum li cas tshaj ntsug kev taw qhia ntawm lub shrinkage tus nqi, thiab txhaj molded. qhov chaw warpage deformation (ie anisotropy).Feem ntau, cov shrinkage tsis sib xws tsuas yog ua rau kev hloov pauv ntawm cov ntim ntawm cov yas, tsuas yog shrinkage tsis sib xws yuav ua rau warpage deformation.

Kev txhaj tshuaj siab, tus nqi thiab lwm yam tsis zoo ntawm lub tshuab txhaj tshuaj, filling thiab txias theem ntawm qhov kub thiab txias, siab, ceev ntawm peb qhov sib txuas ua ke, cov txheej txheem txhaj tshuaj, qhov kub ntawm qhov sib txawv ntawm cov cheeb tsam sib txawv tshwm sim los ntawm thermal stress, thermal deformation los yog tsis sib xws shrinkage uas ua rau lub sijhawm khoov, tuaj yeem ua rau cov khoom yas warpage deformation

(1) Txo qhov kev txhaj tshuaj siab thiab txo lub sijhawm tuav kom paub meej qhov kub txaus ntawm cov yaj kom tsis txhob muaj kev sib ntaus sib tua vim muaj kev ntxhov siab sab hauv.

(2) Txo cov pwm kub thiab nce lub sij hawm txias kom tsis txhob overheating ntawm ib feem thaum demoulding thiab ejection deformation.

(3) Txo cov ntsia hlau ceev thiab rov qab siab kom txo qhov ntom ntom thaum tswj hwm tus nqi tsawg kawg nkaus kom tsis txhob muaj kev ntxhov siab sab hauv.

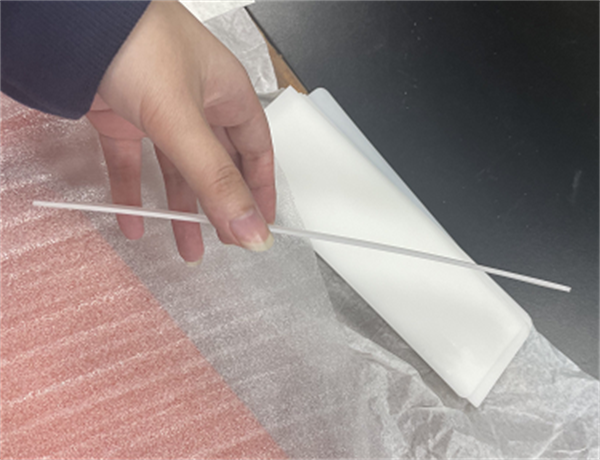

(4) Yog tias tsim nyog, muag pwm shaping lossis demoulding tom qab demoulding tuaj yeem nqa tawm rau qhov chaw uas muaj kev sib tsoo thiab deformation.

Thaum txhaj tshuaj molding, yuav muaj ntau yam teeb meem, Xiamen Ruicheng muaj ntau tshaj 20 xyoo dhau los hauv daim teb no, uas tuaj yeem muab kev txhawb nqa thiab kev pab rau koj.Koj puas xav paub ntxiv?Tiv tauj peb tam sim no!

Post lub sij hawm: Feb-03-2023