Dhia mus rau ntu

→ Muaj peev xwm

→ Khoom siv

→ Nto tiav

→ Kev ua haujlwm thib ob tom qab txhaj tshuaj molding

→ Vim li cas thiaj xaiv peb rau Kev Txhaj Tshuaj Molding Service

→ Peb cov txheej txheem txhaj tshuaj molding

→ Txhaj Moulding los ntawm Prototyping mus rau ntau lawm

→ Qhov zoo ntawm Txhaj Molding

→ Kev txhaj tshuaj molding

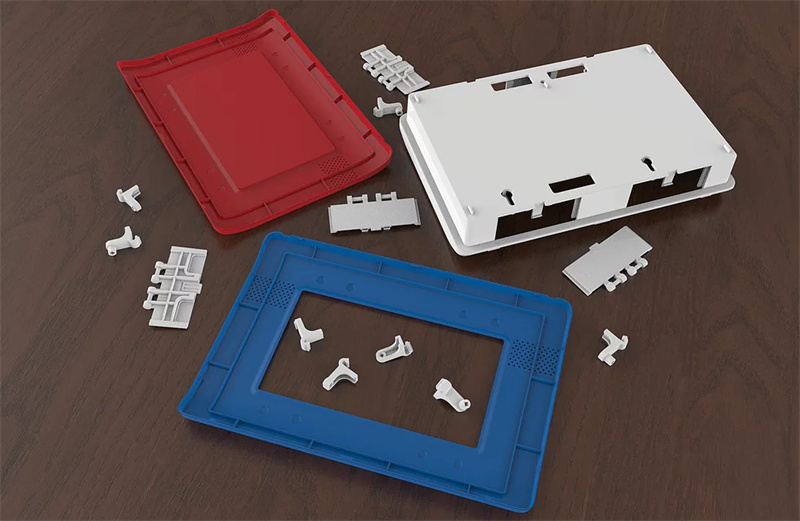

Peb cov txheej txheem yas txhaj tshuaj molding ua cov kev cai prototypes thiab siv cov khoom siv kawg nrogceevcoj.Peb sivsoft toolinguas muaj nqi-npaum tooling thiab accelerated manufacturing cycles, thiab Tshuag txog100 txawv thermoplastic resins.

Cov ntawv thov rau cov yas txhaj tshuaj molding:

- tsawg ntim ntau lawm

- pilot khiav

- functional testing thiab prototyping

Yas Moulding Peev Xwm

Peb cov lus qhia yooj yim rau kev txhaj tshuaj molding muaj xws li kev tsim qauv tseem ceeb los pab txhim kho ib feem pwm muaj peev xwm, txhim khu kev zoo nkauj zoo nkauj, thiab txo tag nrho lub sijhawm tsim khoom.

Tsis pub dhau ob peb teev tom qab peb tau txais 3D CAD qauv, peb mam li xa koj tsim rau manufacturability (DFM) tsom xam thiab real-time pricing .Nrog rau tus nqi, peb cov nqe lus yuav kuj hu tawm tej yam nyuaj rau manufacture nta raws li cov txheej txheem tsim. koj tau xaiv.Qhov no tuaj yeem muaj los ntawm qhov nyuaj rau pwm undercuts mus rau qhov sib sib zog nqus ntawm cov khoom siv machined.

Cov khoom siv thermoplastic

Peb muaj kev xaiv ntau dua 100 cov ntaub ntawv thermoplastic.Thiab yog tias koj tab tom nrhiav rau lwm txoj kev xaiv cov ntaub ntawv, mus saib pebcov khoom hauv qab norau ABS, PC, PP, thiab lwm yam molded yas.

ABS

Acrylonitrile Butadiene Styrene (ABS) yog ib qho thermoplastic uas yog tsim los ntawm emulsion.Nrog nws lub zog, hloov tau, tsis tshua muaj pwm shrinkage (nruj tolerances), tshuaj tsis haum, electroplating muaj peev xwm, ib txwm opaque, qis / nruab nrab nqi..

Cov ntawv thov siv:Automotive (consoles, panels, trim, vents), thawv, gauges, vaj tse thiab khoom ua si.

TPV (Thermoplastic Vulcanizates)

TPV yog ib feem ntawm TPE khoom tsev neeg.Nws muaj qhov ze tshaj plaws hauv cov khoom rau EPDM roj hmab thiab muaj qhov kub thiab txias tsis kam thiab elastisity zoo heev.

Cov ntawv thov siv: Automotive daim ntaub ntawv, khoom siv hauv tsev, sealing daim ntaub ntawv

PEI (ULTEM)

PEI yog cov yas xim amber nrog kub tsis kam thiab siab dielectric zog, ua rau nws zoo rau cov khoom siv kho mob thiab cov hluav taws xob rwb thaiv tsev.

Cov ntawv thov siv: Cov khoom siv hluav taws xob (connectors, boards, keyboards), npog, Cov khoom siv kho mob

Cov iav uas muaj Polycarbonate yog cov khoom siv muaj zog thiab tawv zoo tagnrho rau ntau daim ntawv thov kev lag luam.

Cov ntawv thov siv: Pulleys, khoom siv kho mob

PMMA (Acrylic)

PMMAyog pob tshab polymer nrog zoo tensile, khawb resistant, taupob tshabthiaboptical clarityin tus nqi qis / nruab nrab

Cov ntawv thov siv:zaub sawv, pob qhov rooj, lo ntsiab muag, lub teeb vaj tsev, panels, reflectors, kos npe, txee, tais

PP++ iav-Filled

Iav Filled PP Compound yog tsim los ntawm kev sib xyaw Polypropylene Homo-Polymer nrog qib zoo ntawm iav, nrog rau qib tsim nyog ntawm kev pab cuam, Thaum tshav kub kub stabilizer thiab Anti-oxidant.

Cov ntawv thov siv: Housing handles, enclosures

HDPE (Polyethylene - High Density)

HDPE yog tawv thiab tawv nrog cov tshuaj tiv thaiv zoo heev, lub zog tensile siab, siab cuam tshuam tsis kam thiab siab melting point.

Cov ntawv thov siv: Lub rooj zaum, vaj tse, npog, ntim thiab kaus mom

LDPE(Polyethylene - Tsawg ntom)

LDPE yog mos, hloov tau, tawv, thiab lub teeb yuag nrog zoo corrosion kuj nyob rau hauv tej yam ntuj tso waxy tsos thiab tsis tshua muaj nqi.

Cov ntawv thov siv:Ntim, hnab, tubing, chav ua noj, vaj tse, npog

ASA (Acrylonitrile Styrene Acrylate)

ASA yog ABS lwm txoj hauv kev nrog kev txhim kho huab cua.

Cov ntawv thov siv: Automotive qhov chaw Enclosures, loj panels

HIPS(High Impact Polystyrene)

HIPS yog ib qho yooj yim rau pwm, rov ua dua, thiab muaj kev cuam tshuam siab zog thiab nruj.

Cov ntawv thov siv: Packing, tais diav, zaub

GPPS (Polystyrene - Lub hom phiaj dav)

GPPS yog nkig, pob tshab tab sis tus nqi qis.

Cov ntawv thov siv: Kev ntim cov tshuaj pleev ib ce, cwjmem

PPO (Polyphenylene Oxide)

PPO muaj qhov zoo ntawm qhov ruaj khov thiab cov khoom siv hluav taws xob zoo nrog kev nqus dej tsawg thiab tus nqi siab

Cov ntawv thov siv: Automotive (tsev, vaj huam sib luag), cov khoom siv hluav taws xob, vaj tse, cov kav dej

PET (Polyethylene terephthalate)

PET yog cov khoom siv ntau tshaj plaws rau lub raj mis yas dej thiab lwm yam dej haus.Nws tseem yog feem ntau hu ua polyester thiab yog siv los ua hluavtaws fibers.

Cov ntawv thov siv:Yas dej fwj, ntim

PBT (Polybutylene Terephthalate)

PBT zoo ib yam li PET yas thiab ib tug tswv cuab ntawm tsev neeg polyester.PBT yog qhov zoo dua los ua kom qis molding thiab siv qhov kub thiab txias.Nws muaj kev kub siab thiab tshuaj lom neeg.

Cov ntawv thov siv: Automotive (filters, handles, twj), bearings, cams, hluav taws xob Cheebtsam (connectors, sensors), gears, vaj tse, rollers, keyboards

PPA (Polyphthalamide)

PPA yog piv rau nylon nrog ntau zog, lub zog, thiab thermal zog.Nws muaj zoo creep kuj thiab dimensional stability.

Cov ntawv thov siv: Automotive, roj thiab roj, cov kav dej

PE (Polyethylene)

PE muaj qhov tsis tshua muaj melting point, siab ductility, siab cuam tshuam lub zog, thiab tsis tshua muaj kev sib txhuam.

Cov ntawv thov siv: Zaj duab xis, hnab, hluav taws xob rwb thaiv tsev, khoom ua si.

PP (Polypropylene)

PP yog nyob rau hauv lhnyavnrogtshav kub tsis kam, siab tshuaj tsis kam, khawb kujthiabnatural waxy tsosuas yogtawv thiab tawvin tus nqi qis.

Cov ntawv thov siv: Automotive (bumpers, npog, trim), fwj, kaus mom, crates, tes, vaj tse

PC/ABS

PC / ABS yog kev sib xyaw ntawm polycarbonate thiab ABSuas yog kom tau covCov khoom zoo tshaj plaws ntawm ob qho tib si hauv paus cov ntaub ntawv - tshav kub tsis kam thiab yoog raws.Qhov kev sib xyaw no tseem ua tau yooj yim dua thaum txhaj tshuaj molding dua li ntawm cov ntaub ntawv hauv paus.

Cov ntawv thov siv: Enclosures, loj panels;

PBT +iav puv

iav puvPBTNws muaj zog tensile ntau dua li tus qauvPBT.Nws kuj muaj qhov kub thiab txias thiab tshuaj tiv thaiv.

Cov ntawv thov siv: automotive applications, Fire-retardant applications

PC(Polycarbonate)

PC yog heevtawvnrogkub tsis kamthiabdimension stability,tuaj yeem ua taupob tshabtab sis hauvtus nqi siab.

Cov ntawv thov siv:Automotive (panels, lo ntsiab muag, consoles), fwj, ntim, vaj tse, lub teeb npog, reflectors, kaus mom hlau thiab ntaub thaiv npog

PVC (Polyvinyl Chloride)

PVC muaj zog hardness, mechanical thiab hluav taws xob rwb thaiv tsev.Nws yog tshuaj resistant rau ntau cov kua.

Cov ntawv thov siv: Cov thawv kho mob, cov khoom siv hauv tsev, cov kav dej, cables

PEEK (Polyetheretherketone)

PEEK muaj qhov kub thiab txias, tshuaj lom neeg, thiab hluav taws xob tiv thaiv nrog kev nqus dej tsawg.

Cov ntawv thov siv:Aircraft Cheebtsam, hluav taws xob connectors, twj impellers, seals

PPS (Polyphenylene Sulfide)

PPS muaj lub zog siab heev thiab kub ua haujlwm nrog cov dej ntws zoo thiab qhov ruaj khov.

Cov ntawv thov siv:roj system Cheebtsam, kev taw qhia, keyboards, hluav taws xob rwb thaiv tsev, daim nyias nyias, ntim

SAN (Styrene Acrylonitrile)

SAN (AS) yog cov khoom siv polystyrene nrog cov thermal thiab tshuaj lom neeg ntau dua thiab muaj zog hydrolytically ruaj khov.

Cov ntawv thov siv: Cov khoom siv hauv tsev, pob qhov rooj, koob txhaj tshuaj

TPE (Thermoplastic Elastomer)

TPE muaj lub ntsej muag zoo li cov khoom siv roj hmab tab sis yog cov thermoplastic uas tuaj yeem rov ua dua.TPE muaj cov khoom siv thermal zoo thiab ruaj khov ntawm ntau qhov kub thiab txias uas tuaj yeem ua rau sib txawv hardness.

Cov ntawv thov siv: Automotive applications, khoom siv hauv tsev

TPU (Thermoplastic polyurethane)

TPU yog cov khoom siv elastic nrog zoo tiv taus roj, roj, thiab puas.

Cov ntawv thov siv: Kev siv cov cuab yeej kho mob, mobile electronic devices

Acetal / POM (Delrin)

POMyog ib qho kev sib txhuam qis, lub teeb yuag thermoplasticuas yog muaj zog thiab nruj nrog zoo heev qaug zog kuj, zoo heev creep kuj, tshuaj tiv thaiv thiab noo noo kuj nyob rau hauv ib txwm opaque dawb nrog tsawg / nruab nrab nqi.

Cov ntawv thov siv: Bearings, cams, gears, handles, rollers, rotors, swb guides, li qub

Nylon - iav ntim & 6/6

Nylon 6/6 muaj zog txhua yam thiab rigidity nrog qaug zog tsis kam, tshuaj tiv thaiv nyob rau hauv qis creep thiab tsis tshua muaj kev sib txhuam nrog nruab nrab / siab nqi

Cov ntawv thov siv: kov, levers, me me vaj tse, zip ties & zog, bushings

Nylon - iav puvNws muaj zog tensile zoo dua li tus qauv Nylon.Nws kuj muaj cov coefficient tsawg ntawm kev sib txhuam thiab siab thermal kuj.

Cov ntawv thov siv: Bearings, ntxhua khaub ncaws, lub teeb yuag hloov rau cov hlau yog qhov tsim nyog

Nto Finish Options

Cov kev xav tau ntawm lub kaum sab xis yuav txawv ntawm qhov kev thov tiav.Ntawm Xiamen Ruicheng,Kev lag luam tus qauvSPI thiab VDI classification systemstiav lawm muaj.

Saib peb nplooj ntawv qhia kev tsim qauv kom paub meej ntxiv

| Glossy | Semi-Glossy | Matte | Textured |

| SPI-A1 | SPI-B1 | SPI-C1 | SPI-D1 |

| SPI-A2 | SPI-B2 | SPI-C2 | SPI-D2 |

| SPI-A3 | SPI-B3 | SPI-C3 | SPI-D3 |

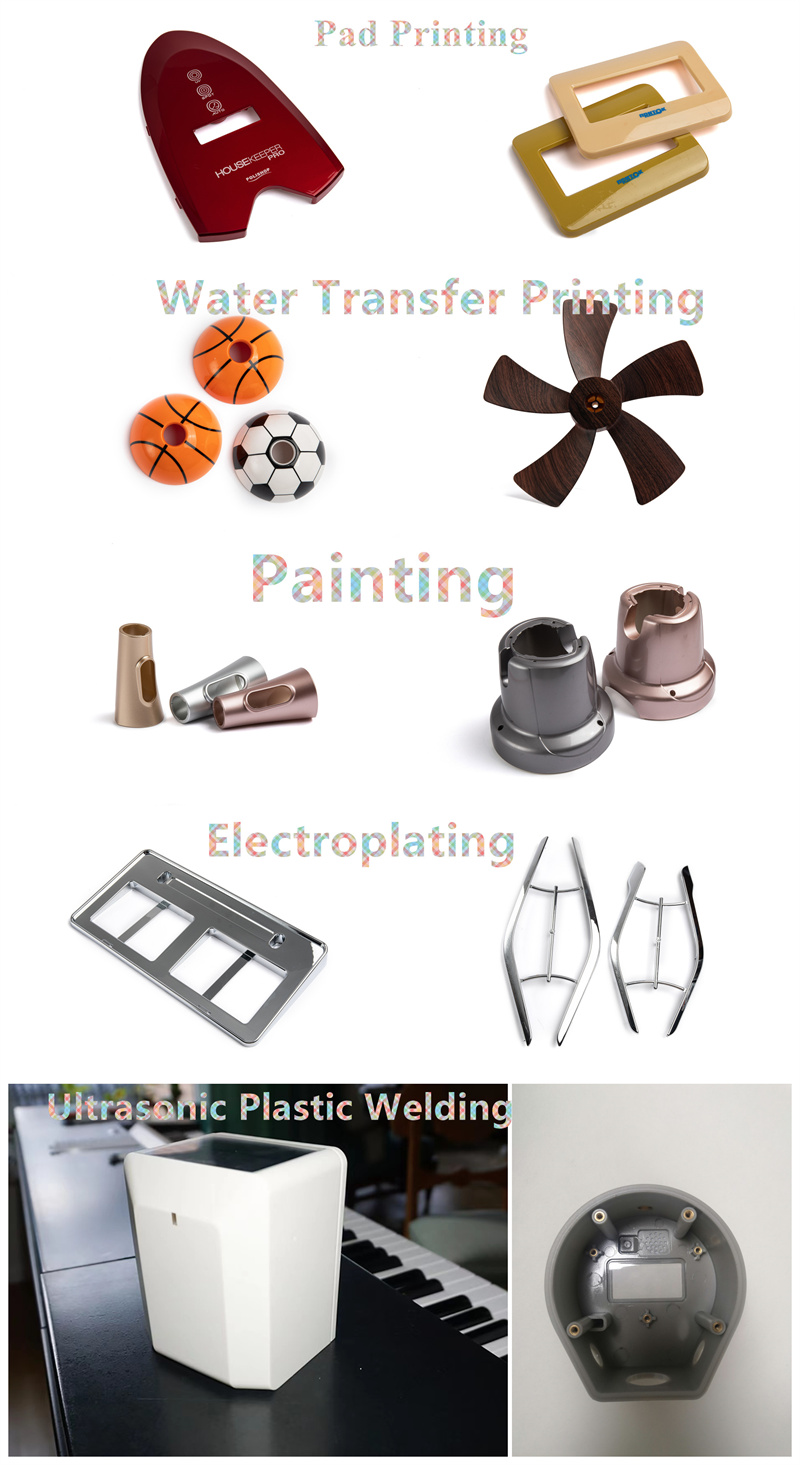

Kev ua haujlwm thib ob tom qab txhaj tshuaj molding

Kub Staking

Cov txheej txheem ntawm cov cua sov hauv zos rau cov khoom siv yas kom hloov kho thiab ntxig rau lwm cov khoom (xws li threaded insert).

Laser Engraving

Engraving ntawv los yog tsim nrog kev siv lub laser.

Pad Printing

Pad printing yog txheej txheem luam ntawv uas tuaj yeem hloov 2D duab / logo / ntawv mus rau 3D nto.

Kev pleev xim

primer thiab sab saum toj txheej;txheem xim los yog Pantonelos yog RAL ximsib txuam;daim npog qhov ncauj muaj;EMI (tooj liab).Glossy, Matte thiab Smooth Texture yog txhua yam muaj los siv rau

Electroplating

Nws yog txheej txheem tsim cov hlau txheej ntawm cov khoom siv hauv qab los ntawm kev txo cov cations ntawm cov hlau los ntawm kev siv hluav taws xob ncaj qha.

Ultrasonic Yas Vuam

Lub tshuab hluav taws xob ntau zaus tsim hluav taws xob los koom lossis hloov kho cov thermoplastics.

Vim li cas thiaj xaiv peb rau Kev Txhaj Tshuaj Molding Service

Xiamen Ruichengmuab kev txhaj tshuaj molding siab heev, nrog cov kev daws teeb meem npog cov khoom pov thawj, cov cuab yeej tsim, prototyping & ntau lawm, xov, thiab kev ruaj ntseg zoo.Peb pab pawg kws tshaj lij tau cog lus los muab kev txhawb nqa kev tshaj lij.Nrog cov prototypes meej thiab ntau lawm,Xiamen Ruichengpab koj mus txog koj lub hom phiaj tsim khoom.

Peb cov txheej txheem txhaj tshuaj molding

Xiamen Ruicheng's txhaj tshuaj molding txheej txheem suav nrog cov ncauj lus kom ntxaws tsim kev tsom xam thiab cov kws tshaj lij pwm cov cuab yeej tsim khoom.Ua kom zoo dua ntawm kev ua tib zoo tsim thiab tsim cov cuab yeej txhaj tshuaj pwm rau koj qhov kev cai yas.Peb yuav ua haujlwm nrog koj los tshuaj xyuas cov qauv T1 ua ntej peb pib tsim cov ntim qis.Txhua qhov kev tsim khoom xaus nrog kev tshuaj xyuas nruj thiab kev tswj xyuas kom ntseeg tau tias koj cov khoom ua tau raws li cov qauv thoob ntiaj teb.

Thov Instant Quote

Peb lub vev xaib kev tshaj tawm online tuaj yeem pab koj kom tau txais cov lus qhia tam sim raws li qhov kev thov kom peb cov engineers tuaj yeem xa cov lus tsocai li ntawm 24 teev kom pib tsim khoom.

DFM Report

Peb tus qauv tsim rau kev tshuaj xyuas kev tsim khoom ua rau peb pom qhov tsis xws luag lossis kev txhawj xeeb ua ntej thiab muab cov lus pom zoo rau kev tsim ua tau zoo dua.

Pwm Flow Analysis

Siv cov qauv kev twv ua ntej tso cai rau peb pom tias cov khoom siv molten yuav coj li cas thaum nws nkag mus rau hauv pwm, tso cai rau kev txhim kho ntxiv rau kev tsim.

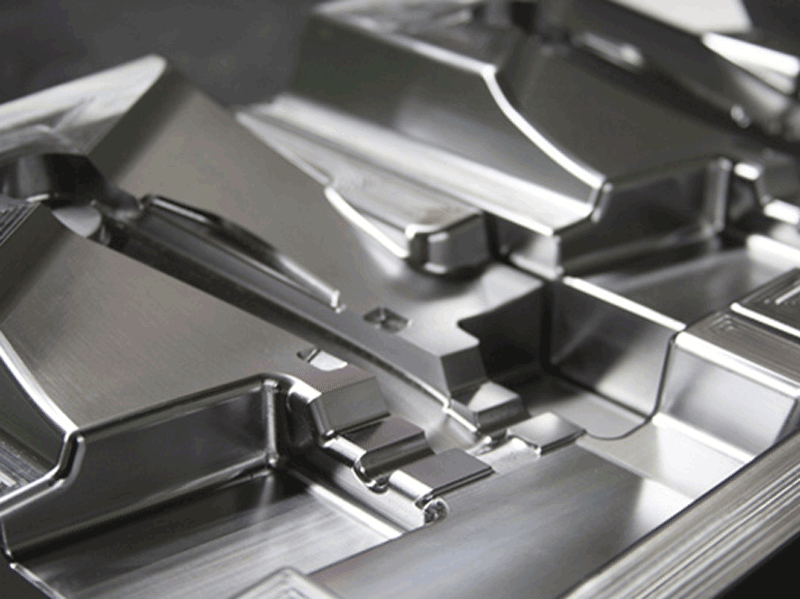

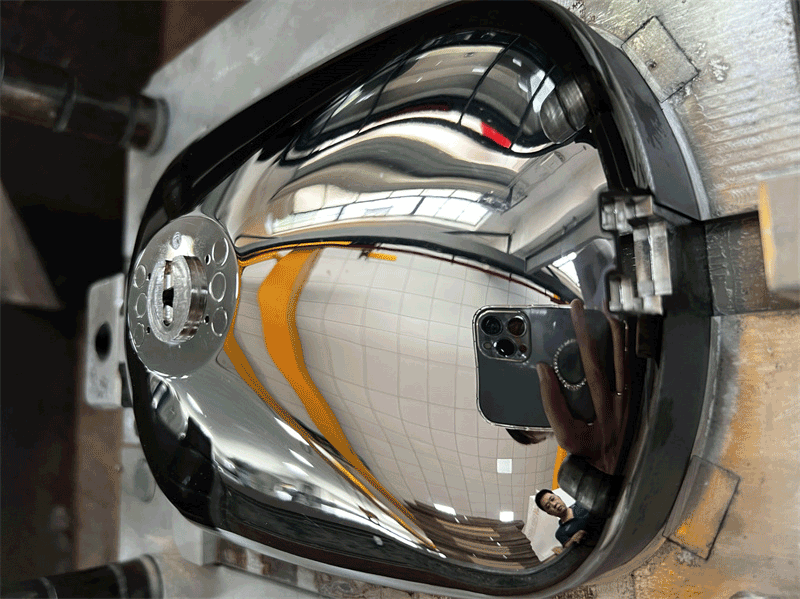

Pwm Tooling Production

Peb siv cov cuab yeej zoo CNC machining los pab tsim cov pwm txhaj tshuaj, ua kom cov pwm npaj siv.

T1 Sample Inspection

T1 qauv yuav raug xa tuaj rau koj los tshuaj xyuas ua ntej tsim cov khoom yas kom paub meej thiab zoo.

Tsawg Volume Production

Tom qab lub sijhawm sim ntau lawm, peb pib batch ntau lawm los tsim cov khoom ntawm tus nqi nrawm kom txuag tau sijhawm thiab nqi.

Kev soj ntsuam nruj

Peb ua raws li cov qauv kev kam rau siab thoob ntiaj teb kom ntseeg tau tias peb cov khoom ua tau raws li koj qhov kev txwv

Kev xa khoom

Peb koom tes nrog cov tuam txhab logistics los teem sijhawm xa tuaj rau koj cheeb tsam.

Txhaj Molding los ntawm Prototyping mus rau ntau lawm

Soft Tooling

Tau txais kev tawm tswv yim tsim tau yooj yim thiab siv tau los ntawm kev ua haujlwm zoo tshaj Soft tooling.Tsim cov khoom me me ntawm cov yas molded qhov chaw nrog zoo heev txhaj tshuaj molding prototypes.Peb ua tau zoo ntawm kev tsim pwm pwm nyob rau hauv hnub kom paub tseeb tias koj ua cov kev ntsuam xyuas ua haujlwm thiab ua kom muaj txiaj ntsig kev lag luam.(Soft Tooling Hom Muaj Ntau <2,000)

Kev tsim khoom siv zog

Peb tsim cov khoom lag luam zoo siab tawv pwm rau cov khoom ntim yas ntau lawm.Nrog lub zog siab, cov khoom siv ruaj khov steel, peb cov cuab yeej tsim khoom tsim nyog rau kev tsim ntau pua txhiab qhov chaw.Peb tuaj yeem sib txawv cov ntaub ntawv thiab kev tsim kho raws li koj qhov kev xav tau tshwj xeeb.

Qhov zoo ntawm Txhaj Molding

Txhaj tshuaj molding yog cov txheej txheem tsim khoom yas uas tuaj yeem tsim cov khoom zoo ntawm cov nplai.Nws feem ntau yog siv rau qis-rau siab-ntim ntau lawm tab sis peb cov cuab yeej siv txhuas tuaj yeem ua rau kev tsim qauv siv nyiaj txiag.

✔ Tus nqi qis ntawm cov ntim ntau dua

✔Exceptional ib feem tshuaj pleev ib ce thiab nto tiav

✔Rov ua dua

✔Qhov nyuaj

✔Tsawg seem seem

✔Kev xaiv loj ntawm cov khoom siv thermoplastic thiab cov khoom siv thermoset

Kev txhaj tshuaj molding

Kev txhaj tshuaj molding yog dav siv rau cov khoom siv yas hauv kev kho mob, cov neeg siv khoom, thiab kev lag luam tsheb.Yam khoom muaj xws li:

✔ Tsev nyob

✔Brackets

✔Gears

✔Ib leeg siv cov khoom kho mob

✔Hluav taws xob connectors

✔Cov koob txhaj tshuaj

✔Ntim

Txuas ntxiv thiab cov peev txheej

Txhaj tshuaj molding nto tiav daim ntawv qhia - DFM

Txhaj tshuaj molding nto tiav raws li SPI thiab VDI kev faib cov tshuab - Gloss, semi-gloss, matte thiab textured nto tiav.Cov ntsiab lus nyob rau hauv tsab xov xwm no Dab tsi yog Kev Txhaj Tshuaj molding nto tiav?Vim li cas thiaj siv cov khoom tiav hauv kev txhaj tshuaj molding?Txhaj...

Puas Yog Yas Txhaj Pwm Hnav Tawm lossis Muaj Lub Neej Ntau Lawm?

Cov yas txhaj tshuaj pwm tuaj yeem hnav tawm vim kev sib txhuam lossis rov sib cuag ntawm qhov chaw ntau txhiab lub voj voog.Kev hnav feem ntau cuam tshuam rau lub rooj vag, swb, ejectors thiab lwm yam txav hauv cov pwm.Thaum cov khoom swb los yog kov ib ...

Xaiv cov khoom siv rau koj cov yas txhaj tshuaj pwm

Txij li thaum muaj ntau yam khoom siv rau kev cai yas molding, nws yog qhov zoo tshaj plaws rau cov khoom engineers tsom rau qhov tseem ceeb ntawm kev ua haujlwm thiab kev ua haujlwm ntawm lawv qhov chaw.Qhov no tso cai rau kev nqaim ntawm cov khoom siv zoo rau koj cov kev cai txhaj tshuaj mo ...